Carelabs is authorized provider of Electrical Installation’s Study, Analysis, Inspection, and Certification services in UAE, and offer earth ground testing service.

Electrical safety test is essential to ensure safe operating standards for any product that uses electricity. Various governments and agencies have developed stringent requirements for electrical products that are sold world-wide.

Ground test is the verification that resistance between your grounding system and earth meets the standard specification. Poor grounding not only increases the risk of equipment failure; it is dangerous. Facilities need to have adequately grounded electrical systems so in the event of a lightning strike, or utility overvoltage, current will find a safe path to earth.

Over time, corrosive soils with high moisture content, high salt content, and high temperatures can degrade ground rods and their connections. So although the ground system, when initially installed, had low earth ground resistance values, the resistance of the grounding system can increase if the ground rods are eaten away.

Laboratories are required to maintain earth resistance to less than 1 ohm and earth to neutral voltage to less than 1 volt.

Carelabs follow DEWA recommendation, and adhere to BS7671 IET wiring regulation standards, and as some clients demand, IS 3043 standards also.

Why is Earth Ground Testing Necessary?

The measurement of ground resistance for an earth electrode system is very important. It should be done when the electrode is first installed, and then at periodic intervals thereafter. This ensures that the resistance-to-ground does not increase over time. The International Electrical Testing Association specifies ground electrode testing every three years for a system in good condition with average up-time requirements.

Poor grounding not only increases the risk of equipment failure; it is dangerous too. Facilities need to have adequately grounded electrical systems so in the event of a lightning strike, or utility overvoltage, current will find a safe path to earth. Over time, corrosive soils with high moisture content, high salt content, and high temperatures can degrade ground rods and their connections. So although the ground system when initially installed had low earth ground resistance values, the resistance of the grounding system can increase if the ground rods are eaten away.

It is recommended that all grounds and ground connections be checked annually as a part of normal predictive maintenance plan.

If our technician finds an increase in resistance of more than 20 percent, we will investigate the source of the problem and make the correction to the grounding system to lower the resistance.

How do We Conduct Earth Ground Testing?

We use several methods to do a ground test. All of them use at least two reference ground points and a current source.

Basic tests that we conduct are as follows:

- Soil Resistivity Testing

- Fall-Of-Potential Test

- Ground Impedance Measurements

- Selective Measurement Testing

- Clamp-On Testing

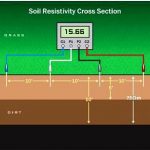

Soil Resistivity Testing

Soil resistivity testing is the process of measuring a volume of soil to determine the conductivity of the soil. The resulting soil resistivity is expressed in ohm-meter or ohm-centimetre. It is most necessary when

determining the design of the grounding system for new installations (green field applications) to meet your ground resistance requirements.

Fall-of-Potential test

This method is used to measure the ability of an earth ground system or an individual electrode to dissipate energy from a site. For the 3-pole Fall-of-Potential test, two earth stakes are placed in the soil in a direct line—away from the earth electrode. The fall-of-potential test method is used to measure the ability of an earth ground system or an individual electrode to dissipate energy from a site. The earth electrode of interest must be disconnected. The tester is then connected to the earth electrode. Then, two earth stakes are placed in the soil in a direct line – away from the earth electrode, for the 3-pole fall of potential test. Spacing of 20 m is normally sufficient.

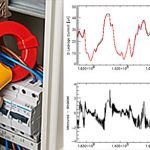

Ground Impedance Measurements

When attempting to calculate possible short-circuit currents in power plants and other high voltage/current situations, determining the complex grounding impedance is important since the impedance will be made up of inductive and capacitive elements.

This test uses a special transformer to induce an oscillating voltage (often 1.7 kHz) into the grounding system. Unlike the 3-point Test which requires the grounding system to be completely disconnected and isolated before testing, this method requires that the grounding system under test be connected to the electric utilities (or other large grounding system such as from the telephone company) grounding system (typically via the neutral return wire) to provide the return path for the signal. This test is the only test that can be used on live or ‘hot” systems.

Selective Measurement Testing

Selective testing is very similar to the Fall-of-Potential testing, providing all the same measurements, but in a much safer and easier way. This is because with Selective testing, the earth electrode of interest does not need to be disconnected from its connection to the site! The technician does not have to endanger himself by disconnecting ground, nor endanger other personnel or electrical equipment inside a no grounded structure.

Clamp-on Testing

The clamp-on methodology is based on Ohm’s Law. A known voltage is applied to a complete circuit and the resulting current flow is measured. The resistance of the circuit can then be calculated. The clamp-on ground tester applies the signal and measures the current without a direct electrical connection. The clamp includes a transmit coil that applies the voltage and a receive coil that measures the current.

Application Sites for Earth Ground Testing are:

- Cellular sites/microwave and radio towers

- Electrical substations

- Remote switching sites

- Lightning protection at commercial/ industrial sites

Carelabs is authorized provider of Electrical Installation’s Study, Analysis, Inspection, and Certification services in UAE, and offer Earth Ground Testing service.