Serial Blast Chillers lowers food temperature below 40°F which eliminates the bacterial contamination risk and ensure food quality. The capacity range varies depend upon the amount of cooked items for commercial use. Reach-in Blast chillers cut-down the temperature of sultry foods to chilled form to extend food lifetime and improve productivity. Roll-in & Pass-Thru Blast Chillers integrated into a hefty walk-in layout and used as stand-alone units. It includes stainless steel holder to accommodate storage demand and the thick polyurethane isolated panels assure chilling potency. By furnishing kitchen with Residential blast chillers, you will be capable to bring down the temperature of the products over the crisis zone so that bacteria contagion doesn’t evolve.

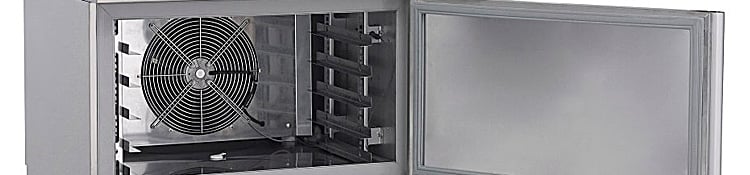

Air Blast Chillers provide soft chilling which cools delicate food without molder, while hard option is used for dense foods. Later it switches to storage mode and holds the food at correct temperature before the operator is ready. Spiral blast chiller calibration helps to prolong the period of the products and maintains the quality. They offer an organized method of cooling the products in a rapid and hygiene manner. Spiral blast chillers cut bacterial growth and conserve food quality. Precision Blast Chiller which lowers the temperature of the product rapidly either fresh or pre-cooked and maintain its traits. The Equipment Calibration gives the rate of chilling or freezing is essential, as it figure out the quality of the product at serving time. Use of blast chillers is prescribed for the restaurants equipment calibration of the European Unions. Blast chillers an exorbitant asset needed in any restaurants equipment calibration.

Depend upon the needs, the range of models vary for the commercial kitchen equipment calibration. Commercial Blast chiller cools food to safe temperature at rapid intervals. The selections of the commercial equipment calibration depends upon the low or high content demand. These calibration not only prevent the contagion threat but also extent the product lifetime. They featured with assorted modes such as quick freeze, soft chill and hard chill so on.

Industrial Blast Chillers used to chill considerable quantities at once. The size and cost range varies depend upon the facility scale demand. Industrial equipment calibration not only reserve appearance and quality of the product but also retains the flovor, the most important nutritional value. Industrial blast chiller maintenance is significant, as temperature stability is key for HACCP industrial equipment calibrations.

- Clean condenser coil at regular intervals to assure unit chills and optimal energy potency.

- Maintain desired airflow

- Sustain proper cleaning routine of blast chiller probes to ensure accurate reading and product safety issues.

- To avoid backups cleanse condense water, if drain lines are in-use.

In Catering Equipment Calibration, the advanced airflow design developed to ensure balanced device either chilling or freezing. It also get rid of product dehydration and assure best food maintenance. Carelabs are the Blast chillers suppliers across the UAE, GCC and Middle East & Africa.