Running your generator efficiently is the key to ensuring its longevity and avoiding unnecessary downtime. Standby generators can remain unused for long periods of time, awaiting a power cut before smoothly intercepting it. Even a regular no-load test leaves the standby generator prone to faults incurred through under-use or neglect. These diesel standby generators that run rarely and or lightly loaded can build up fuel deposits in parts of the engine over time, which may leave your standby generator with reduced output capacity when it is needed. Policies. Things like light loading a generator or neglecting scheduled maintenance can lead to unexpected operating costs, excessive wear and increased emissions.

A load test in this situation will ensure that your standby generator will support your load when the occasion arises. Annual load testing is imperative to confirm your generator is capable of handling the demanded load when necessary, and some insurance companies demand it as part of their policy agreement.

Why is Generator Load Bank Testing Done?

In the event of a power failure you want to have peace of mind that your backup generator power supply will spring into action seamlessly on a moment’s notice. But what happens when the power goes out and your generator fails function as expected? The result can often be costly and sometimes catastrophic depending upon your application.

This is precisely the reason generator load bank testing is an essential piece of a comprehensive preventative generator maintenance plan, which you should ideally have conducted on your genset(s) each year. Load bank testing helps to ensure that your generator will be fully dependable and operational, as well as completely capable of the highest possible load it may be required to handle at any critical point in time. Load testing your emergency standby generator system should be part of a standard planned maintenance program for all systems.

Following are the Reasons to Test Your Generator

- To make sure the generator will perform as designed, when it is needed most.

- Monitoring the exercise period to ensure the generator starts and runs as programmed is also important, but does not ensure the generator will operate as designed.

- As the generator ages, the possibility of weaknesses in the system will rise. A good planned maintenance program that includes load testing is the best way to spot and minimize potential weaknesses in a generator system.

- Many systems are not loaded appropriately to eliminate wet-stacking. If a diesel system hasn’t been load tested in over a year, longer testing may be required. This annual testing will reduce the impact wet-stacking will have on a generator system.

A good planned maintenance program that includes regular load testing should be a standard component of a generator system. The regular testing of the system will provide the highest comfort level that when the system is required, it will operate as designed.

What is Generator Load Bank Testing?

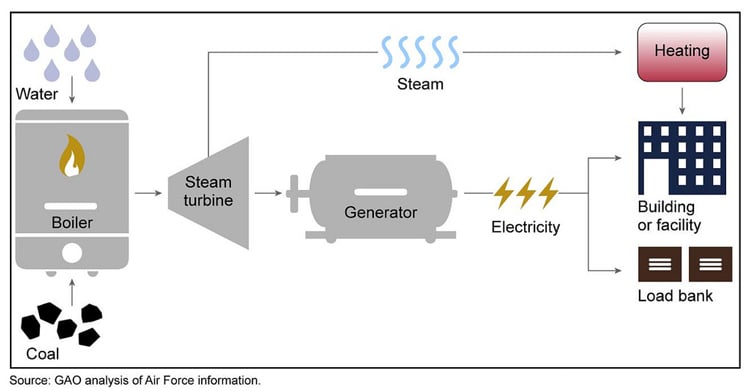

Generator Load Bank Testing is an Important Aspect of Preventative Maintenance. A generator load bank test involves an examination and assessment of a genset. It verifies that all primary components of the generator set are in proper working condition. It involves firing up a standby or prime power generator and running it under an artificial load at its maximum capacity for a specified period of time. Data is recorded that offers a more thorough look into the health of the genset on the whole. The test verifies that the generator is capable of handling incrementally higher kW loads, that it is still capable of accommodating its maximum specified load, and that it can work for an extended period of time.

The equipment used to conduct a load bank test produces artificial loads on the generator by bringing the engine to an appropriate operating temperature and pressure level. This is especially important for standby and emergency generator sets that do not run very often and/or may not be exposed to carrying heavy loads on a frequent basis.

How is a Load Bank Test Work Carried Out?

Placing a 100 percent capacity load on a generator and allowing it to run for a while not only brings to light any problems in the generator and in the engine and its cooling system; it also benefits the engine by properly seating the rings and dislodging build-up in the combustion chambers and on the valves. Diesel engines especially need a periodic load test in order to maintain performance and fuel economy.

At Carelabs we dispatch a portable load bank to the site, allowing the generator to be load-tested safely in controlled conditions, at a time that suits your business. We test the generator over a range of loads, monitoring and gathering data constantly for two to four hours, depending on your requirements.

Step 1

We check all fluid levels in the generator and make sure the fuel tank is full, the oil level is correct, and the radiator or coolant tank is full, if it is a water-cooled generator.

Step 2

The generator is started and allowed to reach normal operating temperature. We watch and listen for any potential problems or abnormal noises. If any problems are noted, the test is stopped until it’s taken care of.

Step 3

Now we begin connecting the loads, beginning with any large 220 volt loads and adding smaller 110 volt loads until each leg carries 50 percent of the maximum continuous rated load of the generator. We do not exceed 50 percent on any one leg. If possible, we use 220 volt resistive loads, such as large space heaters or water heaters. They simplify this step because they apply the load to each leg equally.

Step 4

The amperage of each leg is checked with the ammeter, and the voltage from each leg to neutral is also checked with the VOM set to read AC volts. For a 110/220 volt single phase generator, the voltage of each leg should fall between 105 and 125 volts, and the current should be half of the rated watt output divided by the voltage, for each leg.

Step 5

The generator is monitored while maintaining this load for the duration of the test. We watch for overheating, listen for unusual noises, and monitor the output. If a problem develops, the generator is shut down quickly to minimize damage, and the generator is repaired before returning it to service. How long the test should continue depends upon the type of generator. Light-duty portable generators should not be run at full load for more than three to four hours. Contractor grade generators should be able to run for eight hours. Continuous duty air or water cooled generators should run 24 hours. Larger industrial quality diesel generators should ideally be run under full load for about a week.

Step 6

Last we remove the loads gradually, and allow the generator to run under light load for one hour. All loads are removed for five to ten minutes before shutting the generator down.

Benefits of Load Bank Testing

- Verifies the gensets capabilities opposed to just routinely starting it up.

- Problems discovered early can be significantly less expensive and prevents future major issues.

- Helps to avoid wet-stacking and cleans out carbon deposits.

- Verifies the engine cooling systems will perform while under load.

- Provides assurance that the genset should work properly when you need it most.

- Tests that a gen set is capable of operating at peak specified kW output for a specified amount of time.

- Eases the effects of light loading by burning off the residue that leads to wet stacking.

Carelab’s load testing of generator sets is a wide-ranging service that monitors every critical component of your generator, including the engine temperature as well as the oil pressure. Throughout the testing process, we wisely oversee the entire unit, ensuring that it is run at normal operating pressures and temperatures once optimal levels are achieved. As part of this service, we provide you with a broad report that includes all your generator’s output readings % load, kW meter, engine speed, power factor, frequency meter, lube oil pressure, water temp, ambient room temp, oil temp, battery voltage, fuel pressure and fuel level as well as any comments and recommendations. As a plus when Carelab’s operates, you will experience no disruption to your facility’s operating schedule during the testing process.

Carelabs is authorized provider of Electrical Installation’s Study, Analysis, Inspection, and Certification services in UAE, and provide Generator Load Bank Testing Service.