Do you work with electrical equipment and/or live wiring? Then you are indebted to provide a safe working environment for yourself and those around you. With an earth loop impedance test from Carelabs, you can avoid electrical hazards and ensure your worksite is compliant.

Why Earth Fault Loop Impedance Test Done?

Because of the severity of coming into contact with an electrical fault, having your electrical installations and power points tested for earth fault loop impedance is crucial. In most homes, basic shock protection is done by organising an earthing circuit with automatic switches in the indoor wiring circuits. This quickly cuts off supply to an earthing circuit where a fault occurs and touch voltage exceeds an acceptable limit.

According to the current national safety standards, you are required to conduct loop impedance test on your premises to ensure the safety of all guests and employees. The electrical earth of all your electrical installations and power points has to be tested to discover any faults within your electric circuit. Having a functional earth return circuit will allow the detection of circuit faults and facilitate a reaction from your MCB (miniature circuit breaker).

What is Done During Earth Fault Loop Impedance Testing?

Proper protection against electric shock hazards is given when the TT wiring system complies with:

Ra x Ia <50,

Where “Ra” is the sum of the resistances of earth bars and protective conductors and “Ia” is the maximum current of the protection system. Ra multiplied by Ia should not be more than 50 V, i.e. the maximum voltage one can touch will not exceed 50 V in the event of an earth fault.

A fault loop impedence test is done between the active conductor and the earth. To test the loop impedance our technician will use an earth loop impedence tester which is plugged into the power socket (GPO) to take a reading.

Carelabs technician will detect the resistance level in your earth return circuit and notify you if it is at the wrong level – it needs to be low enough to allow the circuit breaker to function correctly. Carelabs will inspect and test your electrical wiring and by asking us to test you are protecting both your employees and your liability. It is important to adhere to national legislation to avoid harsh penalties.

Our highly-trained staff are fully mobile and offer earth loop impedance test services across the nation.

How Carelabs Conduct Earth Loop Impedence Test?

- External Earth Fault Loop test sequence:

- Step 1: Earth Fault Loop Tester or Earth Fault Loop Test option is selected on a multifunctional tester such as the Megger 1553.

- Step 2: Test is done on the incoming side of the installation. Connect one test lead to the Line terminal, the second test lead to the Neutral terminal and the third (usually green) test lead to the incoming Earth conductor.

- Step 3: We press the TEST button. The measurement should be a low reading ohm value.

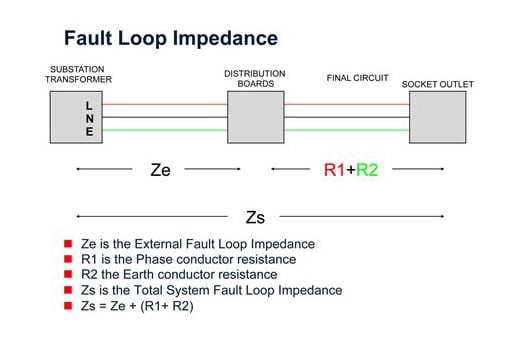

- We record this value of `Ze` on the Electrical Installation Certificate.

- Having obtained the `Ze` value for the installation, the value of `Zs` can be easily calculated for every circuit.

The formula for determining `Zs:

Zs=Ze + (R1+R2)

Zs – earth fault loop impedance of the circuit tested

Ze – earth fault loop impedance external to the supply

(R1+R2) – Sum of the resistance of Line and Earth for the tested circuit.

2. The Earth Fault Loop test sequence:

- Step 1: We locate the furthest point on the circuit to be tested (such as the furthest socket)

- Step 2: With the appropriate Earth Fault Loop Tester, we connect the test leads to the Line, Neutral and Earth terminals.

- Step 3: We measure and write down the test results on the Schedule Of Test Results.

- If the circuit is RCD protected than we will have to select the “No trip” function of the Megger 1553 to avoid nuisance tripping of the RCD. If the tester does not have this option then we will have to link out the RCD.

- Having obtained the value of Zs for every circuit, we will be verifying that these values are within the accepted limits described by BS 7671.

Since the test result is dependent on the supply voltage, small variations will affect the reading. Thus, the test should be repeated several times to ensure consistent results.

A circuit protected by an RCD will need special attention, because the earth-fault loop test will draw current from the phase which returns through the protective system, leading to tripping the RCDs during the tests. Therefore, any RCDs must be bypassed by short circuiting connections before earth-fault loop tests are carried out. It is, of course, of the greatest importance to ensure that such connections are removed after testing. At Carelabs we use an earth loop impedence tester that will not trip out the circuits RCD that we are testing.

After testing is complete, we will give you a retest date (for your next earth loop impedance test) that complies with the national standards. When the time comes, our team will notify you of the retest. All results will be documented in a detailed report that is supplied to each client. Within this report, your equipment will be assigned either a pass or a fail. This document will be kept on file should you need to access it in the future for compliance verification.

Loop Impedance Tests Methods

- 2-wire high current test: This is the traditional loop impedance test. Using a test current of up to 20 A and a simple 2 wire connection, it is most accurate test available.

- 2-wire “No-Trip” dc saturation test: A DC test current was injected in to the circuit prior to carrying out a standard 2 wire high current test. The aim of this DC test was to saturate the monitoring coil within the RCD, allowing enough time for the high current AC test to be carried out.

- 3-wire “No-Trip” test: This test method overcame the need to by-pass even the new electronic protection devices by utilising a low current Line-Earth test current, whilst still returning a degree of accuracy. Not having to by-pass the RCD/RCBO obviously introduced a time saving factor.

- 2-wire “No Trip” test: They allow testing most RCDs and RCBOs without having to bypass them. With no neutral connection required, they maintain a true 2-handed operation, but will no longer indicate reverse polarity or warn of a missing neutral.

- 4-wire grid impedance test: The test uses a 4 wire Kelvin connection, negating internal lead and contact resistance; such is the accuracy of the test. With test currents up to 1000 A, measurements down as low as 10 MOhm can be accurately made.

Earth fault loop impedence testing is a way of insuring that you have made an electrically safe ground connection having a suitably low residual resistance. Short-circuit current in a faulty installation is of insufficient level and the protection device would thus take too long to activate. The delay can be disastrous for life and property. It is therefore necessary to know if the impedance of the path that any fault current would take is low enough to allow sufficient current to flow in the event of a fault and that any installed protective device will operate within a safe time limit.

Carelabs team will conduct all tests and inspections according to the current safety standards. Earth fault loop impedence testing is mandatory for the safety of all employees. Get tested today to make sure your workplace is safe. We are here to assist with all your compliance requirements.

Carelabs is authorized provider of Electrical Installation’s Study, Analysis, Inspection, and Certification services in UAE, and provide Earth Fault Loop Impedence Testing Service.