Polarity in electrical terms refers to the Positive or Negative conductors within a DC circuit, or to the Line and Neutral conductor within an AC circuit. In the context of electricity installations, a polarity test is used to confirm the correct connection of the line and neutral conductors. For example, for an Edison-screw lamp holder, it is important that the line conductor is connected to the centre terminal and the neutral conductor is connected to the outer conductor. Similarly, it’s important to confirm that switches are located in the line conductor not the neutral conductor.

Most multimeters, including digital multimeters, can do this. Regarding alternating current in the context of an AC supply, a polarity test is done to ensure that the line and neutral conductors are connected the correct way around at, for example, electrical sockets, Edison-screw lamp holders, etc.

Why do a Polarity Test?

The purpose of a polarity test to ensure that all single pole devices (fuses, switches and circuit breakers) are connected in the phase conductor only. We cannot simply trust that the electricians have connected things up the right way; everyone makes mistakes, even if it’s your own work. Since ac installations consist of a Live and a Neutral conductor, it is extremely important that these conductors are connected the right way around, within all electrical accessories such as wall sockets or plugs. To ensure this, polarity test is done at each relevant point. This simple test is just as important as all the others, and many serious injuries and electrocutions could have been prevented if only polarity checks had been carried out.

There are 4 different scenarios that require a polarity test, these are.

- All single pole devices (fuses, switches and circuit breakers) are connected in the phase conductor only.

- The phase conductor must be connected to the centre terminal of an Edison screw lamp holder (with the exception of E14 & E27 lamp holders, these are European and occasionally crop up in the exam).

- All polarities of socket outlets (ring & radial) must be verified.

- The polarity of the mains supply must be correct, using an approved voltage tester. (This is done with the supply connected, therefore carried out at a different stage then the above three).

What is Polarity Testing?

A test that creates a circuit using the phase conductor and the single pole device in question, breaking the circuit when operating the device, means that the reading on the instrument will change, and thus confirming that that device must be connected in the phase conductor.

This test will verify that all the switches installed in the system are connected in current carrying conductor and not in neutral. For example, if you isolate or switch the neutral of a circuit via a single-pole circuit breaker or switch, it would appear that the circuit is dead where in fact it is still live.

If polarity is not correctly determined there may be a risk of electric shock during maintenance procedures.

There are 2 methods that can be adopted when conducting a polarity test. These are described below:

Method 1 for Polarity Test

This method is exactly the same as test method one for ‘Continuity Of Protective Conductors’ if we take a lighting circuit, by putting a temporary link between phase and circuit protective conductors (cpc), at the consumers unit and our instrument at lamp holders themselves, we are creating a circuit. When we operate the light switch, the instrument changes, and then changes back to the original reading on operation of the switch again. If the reading did not change, then the switch is likely to be connected in the Neutral. (Not good!) With a little foresight this could be carried out at the same time as the continuity test. The only difference being, for radial circuits every point must be tested. The main benefit with this is it allows you to conduct 2 tests at the same time, polarity and R1 + R2.

Method 2 for Polarity Test

This method, like wise is similar to test 2 of the continuity test, we simply use a wander lead as the return lead. There is little use for this method, within the polarity test. Method 1 is less clumsy, and is far more flexible and useful.

How is Polarity Test Done?

We perform following steps for polarity testing:

Step 1: Polarity by Visual Inspection

By using our knowledge and sight, correct termination of cables relating to core colours can be established. It is essential that polarity is checked visually during the process of installation, especially in cases where checking by testing is impractical.

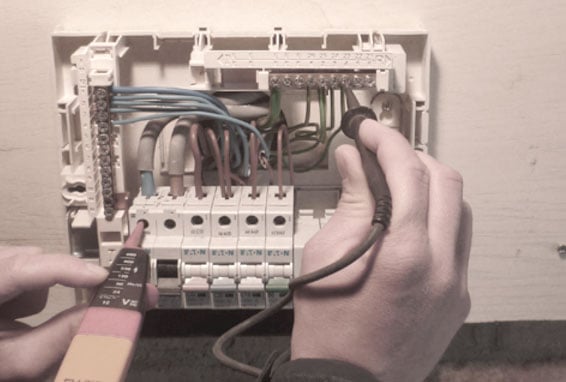

Step 2: Polarity by Continuity Testing

If visual inspection is not possible, we will need to use a low-resistance ohmmeter for this test. When we perform continuity test radial and ring final circuits, part of the process is to test and visually inspect the polarity of fixed equipment and socket outlets.

Steps:

- We switch off the circuit breaker supplying the circuit.

- From the specific circuit, we put a temporary link that will connect the line conductor and the CPC or any equipotential bonding conductors. It will serve as a testing point for convenience.

- Continuity test is conducted by placing the test leads across the line conductor and the nearest CPC or any exposed conductive parts of the circuit.

- If the instrument shows zero reading (with continuity sound) then the switch is connected properly to the line conductor.

- If the instrument shows some significant ohmic value then the switch is not connected to the line conductor. We will interchange the connections to fix the problem.

Step 3: Live Testing for Polarity

If the two methods are not possible due to urgency we can perform live polarity testing by using the approved voltage GS38.

Steps:

- We test between LINE and NEUTRAL terminals.

- We test between LINE and EARTH terminals.

- We test between NEUTRAL and EARTH terminals.

The test instrument should indicate full voltage (230V) between Line-Neutral and Line-Earth conductors. No voltage should be detected between Neutral-Earth

The requirements for polarity test are:

- All fuses and single pole switches are in the phase conductor.

- The centre contact of equipment like lamp holder is connected to the phase conductor.

- All socket outlets and similar accessories are correctly wired.

Although polarity is towards the end of the recommended test sequence, it is sensible, on lighting circuits, for example, to conduct this test at the same time as that for continuity of CPCs. (When recording R1+R2).

We conduct Polarity test for Transformers too. You can contact Carelabs anytime to conduct Polarity test and ensure your apparatus is properly connected to the circuit and save it from damaging.

Carelabs is authorized provider of Electrical Installation’s Study, Analysis, Inspection, and Certification services in UAE, and conduct Polarity Test.