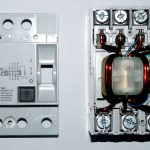

Fixed Electrical Testing involves the testing of electrical services and systems that conduct electricity around a building. It covers all of the hard wiring in a building and includes items such as main panels, distribution boards, lighting, socket outlets, air conditioning and other fixed plant.

Why is Fixed Electrical Testing Required?

The best way to find out if your electrical equipment is safe is to have it inspected and tested by a person who is competent to do so. Many of the potential faults in electrical equipment can be identified with thorough inspection and testing by a competent engineer, but electrical equipment should be tested more thoroughly on a regular basis. The test should be carried out often enough that there is little chance that the equipment will become unsafe between tests. Equipment for use in harsh conditions may need very regular testing whilst equipment in clean, dry, well-controlled environments may need less regular testing. Thus it ensures compliance with the Electricity at Work Regulations 1989 and IEE Wiring Regulations. It reduces costly failures and downtime of the electrical installation. It aids plant managers to budget for electrical work.

What is Done in Fixed Electrical Testing?

Testing electrical installations is always an interesting task. We often get to see the nuts and bolts of most buildings during this process. The whole purpose of electrical inspection and testing is to determine if the wiring within a building is safe for continued use. Referencing the current wiring regulations and the regulations in force at the time of the original installation. It is important to note that we can’t or at least should not make recommendations based on what our ideal installation would look like. Safety is the prime goal and anything unsafe or something that could develop into an unsafe installation is highlighted and coded within our documentation referencing the regulations that apply to such issues. Things that do not meet the current wiring regulations but that are not unsafe or dangerous will be coded or noted for information during future testing or to bring the installation right up to date.

How fixed electrical testing is done?

Step 1: Programming of Works and Progress Meeting

A programme of the sequence of works should be agreed between the users and Carelabs. Prior to commencement on site, a pre-contract meeting with the client end users and our team will be scheduled. The pre-contract meeting will be to discuss the detailed day- to-day arrangements for safe methods of working. Notes of any decisions taken will be circulated and incorporated into the contract arrangements.

Step 2: Method of Inspection and Testing

- First our team shall carry out a Risk Assessment and generate a Method Statement

- We inspect and test all circuits and make all reasonable attempts to identify the full extent of the circuit. Circuits that remain unknown will be identified as such and maximum details possible will be recorded on the test sheets

- In addition, we make all reasonable attempts to identify causes of circuit faults found, including disconnection of fixed equipment or luminaires as necessary

- It is not practical to inspect every joint and termination in an electrical installation. However, we will inspect every termination within distribution systems and distribution boards to ensure that the connections of the conductors are properly installed and secure

- A sample inspection will be made of all accessible parts of the electrical installation. The inspector will make allowance to inspect at least 10% of the termination points per power circuit and at least one luminaire and one switch per lighting circuit. At least one socket outlet in every room should be inspected, regardless of room size

Step 3: Warning Signs

We ensure to provide adequate warning notices, displayed at each entry point, confirming the status of each site area and prohibiting when appropriate.

Step 4: Electrical Safety

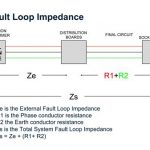

The inspector will not work on any electrical circuit in which all phase (live and neutral) conductors have not been isolated, except where this is necessary to carry out a particular test or procedure (for example: polarity, earth fault loop impedance and the functional testing of RCDs, RCBOs, switchgear and control gear). Before commencing work, isolation should be carried out by either physically removing the links or fuses and by a locking device securing the isolation in an “off” position.

Step 5: Switching off Supplies

The Periodic Inspection and Testing procedure will require isolation of all electrical circuits for various periods of time. It is our responsibility to liaise directly with the building occupants prior to switching off any electrical supplies to agree upon suitable When agreeing the programme of circuit isolation with the occupants, we will make it clear to the occupants that they require total isolation of the electricity supplies to enable the testing to be carried out correctly and in safety as required by the Electricity at Work Regulations (1989). In the event of a project over-running, our inspectors will be prepared to temporarily cease operations until further agreement has been reached with the occupants.

The following list of services can be affected by the isolation of local electrical circuits:

- Intruder alarms

- Mechanical services control systems

- Loop alarms for equipment protection

- Fume extract systems

- CCTV security cameras and recorders

- Lift installations and associated control equipment

- Security screens

- Data network communications racks

- Emergency escape doors

- Fire alarm systems

- Door access systems

- Emergency escape lighting

- Mechanical services plant

- User’s equipment

We also consider the effects on adjacent buildings and systems of such isolations and advise accordingly i.e. Fire Detection and Alarm Systems, Communication Systems, Data Hubs, Computer Systems and Security Systems. We always try to minimise the disruption to supplies, particularly to essential equipment.

- Any requirement to save IT software is identified and actioned prior to the commencement of any electrical operations.

- Any contingency arrangements arising from the absence of electrical supplies are facilitated.

- Appropriate access and relocation/removal of any obstacles will be undertaken.

- All freezers/ fridges contain a minimum amount of perishable food stuffs.

Step 6: Temporary Supplies

Where required, we shall make allowance to provide temporary supplies to the specific locations previously agreed with the users, for use when these area(s) need to be isolated for testing.

Step 7: Re- Energisation

It is our responsibility to ensure that all circuits are operational on re-energisation. Time clocks for heating will be reset to the correct time and reprogrammed as necessary. Fire Detection and Security systems shall be checked

Step 8: Repairs

No repairs or rectification works shall be commenced without first obtaining the correct authority from an appointed member of Origin Housing staff.

Step 9: Dangerous Installations

Where the inspector determines that the condition or particular circumstances relating to an electrical installation represents immediate danger to our employees or any other person property or livestock, inspector shall take immediate action sufficient to remove the danger. This may include temporarily isolating the equipment, installing warning labels etc.

How Often Should Fixed Electrical Testing be Conducted?

The frequency of fixed electrical testing must be determined taking into account:

- The type of installation

- Its use and operation

- The frequency and quality of maintenance

- The external influences to which it is subjected

All buildings shall be subject to a full fixed electrical Test at the prescribed frequency. Partial testing of circuits or installations is not generally permitted. However, should detailed records, test results and drawings be available, the Duty Holder may relax the requirements subject to Risk Assessment. This is especially relevant to properties which may be the subject of short term lets. The frequency should be increased if the history indicates signs of progressive deterioration.

Fixed electrical testing identifies deficiencies in an electrical installation before they become serious hazards. Over time, all electrical installations deteriorate due to age, loading, wear and tear, mechanical damage, overheating, environment, poor maintenance, etc. Legislation requires that electrical installations are maintained in a safe condition and therefore must be periodically inspected and tested.