Secondary injection tests are done to ensure proper functioning of the protection system. Secondary protection system consists of auxiliary relays, protective relays, protection circuits, metering devices, communications and control systems, low-voltage devices etc. Secondary injection test comprises not only the testing of protective relays and their tripping settings, but also the verifying of all related circuits and gears included in the correct functioning of the secondary protection system.

Why is Secondary Current Injection Test Important?

The purpose of secondary injection testing is to check that the protection scheme from the relay input terminals onwards is functioning correctly with the settings specified.

Secondary injection test is done prior to primary injection test, Due to the threats associated with the initial testing to the low voltage side of the device under test are reduced. The primary or high voltage side of the device is detached, so that no harm can occur.

It is a crucial test that should be carried out on a trip unit in the course of a service. By connecting secondary injection test sets we can ensure that the trip unit, associated components and its settings or factory parameters are functioning as they should. It is also an important test for a circuit breaker once a mechanical inspection and service is performed as the breaker is recurrently closed, opened and charged.

What is Done During Secondary Injection Test?

The extent of testing will be largely determined by the client specification and relay technology used, and may range from a simple check of the relay characteristic at a single point to a complete verification of the tripping characteristics of the scheme, including the response to transient waveforms and harmonics and checking of relay bias characteristics. This may be important when the protection scheme includes transformers and/or generators. It is clear that a modern test set can facilitate these tests, leading to a reduced time required for testing.

The secondary injection test involves disconnection of the device and/or circuits and consists of following tests:

- Test all kind of relays: the relay testing through secondary injection test may range from a simple check of some points of the relay characteristic to a complete verification of the protection scheme logic, even including the response to transient waveforms, harmonics, etc.

- Test switches and connections

- Check on-load wiring, trips, alarms and communications circuits, currents and voltage wiring, phase by phase.

- Check phasing and polarity up to the relay terminals.

- Test current, voltage and energy meters, transducers, sensors, motor overload units, etc.

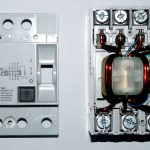

- Check low voltage circuit breakers (if solid-state trip units have accessible terminal blocks for secondary injection test, otherwise the primary current injection is preferred because verifies all the breaker, and not only the trip unit)

How is Secondary Injection Test Performed?

Following are the various tests in secondary injection test:

- Three phase non-directional pick up and drop off accuracy over complete current setting range for both stages

- Three phase directional pick up and drop off accuracy over complete RCA setting range in the forward direction, reverse direction in current angle sweep and forward direction, reverse direction in voltage angle sweep.

- Three phase polarising voltage threshold test

- Precision of DT timer across whole setting range

- Precision of IDMT curves with appealed precision range

- Accuracy of IDMT TMS/TD

- Minimum Pick-Up of Starts and Trips for IDMT curves

- Accuracy of reset timers

- Effect of any blocking signals, opto inputs, VTS, Auto reclose

- Voltage polarisation memory

All the results should be carefully noted and filed for record purposes. Departures from the expected results must be thoroughly investigated and the cause determined. After rectification of errors, all tests whose results may have been affected, even those that may have given correct results, should be repeated to ensure that the protection scheme has been implemented according to specification.

For protection relays, testing at site itself is a usual procedure, but the other equipment in most occasions are sent to a laboratory for calibration, leading to significant costs and efforts.

Testing Modes of Secondary Injection Test

No-Trip Mode

The protective functions of the electronic trip device can be tested, but the trip device won’t send a trip signal to the circuit breakers trip actuator. This test can be performed while the circuit breaker is energized and carrying load current because a no-trip test won’t cause the circuit breaker to open.

Trip Mode

The protective operations of the electronic circuit are checked similar to a no-trip mode test, with the exception that the trip unit will launch a signal to the circuit breakers trip actuator. This will lead to the opening of circuit breaker, this is the reason this test is normally done only when a circuit breaker is removed from its section and therefore detached from the switchgear bus.

Trip test is most suitable for correct a distrusted circuit breaker operation. The self-test function does not validate the functioning of the circuit breakers current sensors and the associated current wiring.

Self-test Mode

Few new solid-state trip gears and protective relays consists of built in self-test operations that needs no discrete test kit. Trip unit self-tests are much simpler to do than any other test and can be performed more often.

Self-test operation doesn’t validates the operation of the circuit breakers current wiring and current sensors.

Circuit Breaker:

- Prior to the installation of a new circuit breaker or returning it back to its service following a maintenance inspection, the breaker must be positioned at its section in the test position and electrically drove by opening and closing its contacts from as many control devices as possible. Verifying proper operation of circuit breaker electrical controls, validates the reliability of control components, control wiring and the source of control power.

- While a circuit breaker is in its test position, the terminating its main contacts may not attach the switchgear line bus with associated load circuit. In such occasions, a circuit breaker must never be verified inside its switchgear section while workers are doing operations on electrical gear that is attached and is live, to the associated load circuit.

Benefits of Secondary Injection Test

- Can test electronic breakers

- Quick

- Tests trip unit

- Easier

- Takes less expertise to run the test

- Test kit is small and portable

- Less expensive