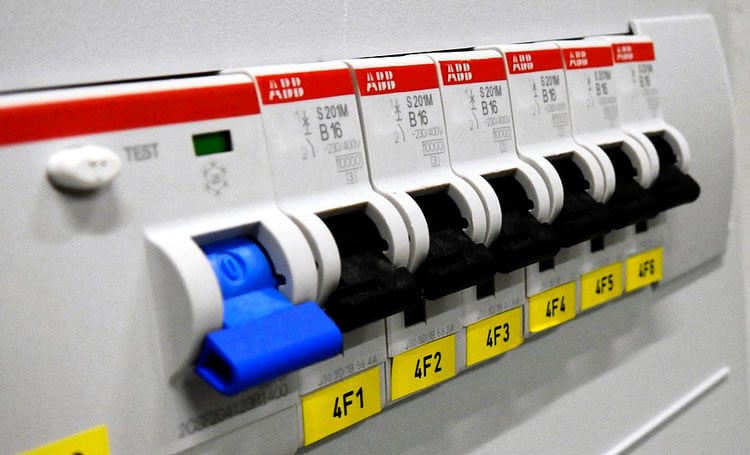

Main Task of Circuit Breakers

- When sealed, they must let the current flow as effectively as possible

- When open, they must insulate the contacts from one another as effectively as possible

- In the event of a malfunction, they must disconnect the fault current as quickly and reliably as possible, thereby protecting all subsequent equipment

A circuit breaker might remain idle for many years, and then, in the occasion of a malfunction, it has to cut off fault currents of several kiloamps reliably within just milliseconds. Typical errors that occurs on circuit breakers are short circuits in the coils, for example because of damaged mechanical connections, because of worn contacts, or damaged insulation. Thus, circuit breakers needs to be carefully tested regularly.

Why Circuit Breaker Testing is Done?

The circuit breakers should carry out the crucial protective function of attaching and detaching the electrical power in a consistent manner; this needs proving their consistency on field tests while installation and with periodical maintenance tests during its lifespan to avoid expensive failures and glitches that could even compromise the safety of the substation.

By studying the current used by the trip coil throughout the circuit breaker’s operation, it is likely to find out if there are any mechanical or electrical issues. Most times, such issues can be limited to assist in finding the core cause. Optionally, checking the tripping supply’s voltage through the operation can help find out problems rising with tripping batteries.

Part of a diagnostic maintenance program includes:

- Finding an early indication of possible problems

- Preventing problems rather than picking up pieces

- Building up a test record database for trending

- Picking out the bad actors

Performing Timing Tests is the best way to verify the control circuit, check motion of the moving parts, validate time of operation, verify manufacturer specifications, determine contact wear, demonstrate results of maintenance and assess overall breaker capability.

What is Done During Circuit Breaker Testing?

In comparison to other electrical equipment such as transformer or machine, testing of circuit breakers is much more challenging because the short circuit current is larger. Separate circuit breaker test equipment are employed to verify the working and state of circuit breakers on the power systems.

How to test a circuit breaker consists of a lot of different test techniques and type of testers; there are few primary deliberations on how to test a circuit breaker, which guides to various preferred functions in the test set, the way to test a circuit breaker varies with the type of breaker (MV/HV/LV) and depends on the element to be verified to find out potential performance problems (tripping time, synchronism, etc.).

For testing a circuit breaker, it is essential that a vast information about the breaker is available, about how it works, reference values of previous tests, its tolerances or initial values with which to compare the actual results, sometimes defined by a rated timing graph. In this way, the way to test a circuit breaker becomes a trending analysis since test results are not always definitive but have meaning just when compared to previous data or results.

How is Circuit Breaker Testing Done?

Routine field testing doesn’t necessarily consists of complicated equipment in order to check a circuit breaker is in operational state. Few regulations and suggestions for these tests consists of regular maintenances and checking that that circuit breaker performance is in order with manufacture’s calibration curves. It is vital that these tests are performed under organised conditions at ambient temperature so will be no alterations in the data. For every breaker resistance testing, load and line conductors must be detached. If not then the test calculations will also consists of the traits of the connected circuit.

Few of the routine maintenance tests are:

Insulation Resistance Test

Resistance testing is important for checking that the insulating material, which renders the moulded cases, of breakers are working properly. In order to check for insulation resistance, an equipment called as “megger” is employed. A megger applies an identified DC voltage to a provided wire for a determined period of time in order to check the resistance within the insulation on that specific wire or winding. It is vital that voltage is applied because resistance tested with an ohm meter may differ if there are no potential differences existing. It must also be observed that if you apply a voltage that is too large for that insulation to endure, then you might potentially harm the insulation. Meggers are rated and have particular settings that range from 300V to 3000 V. Carelabs technicians and engineers are skilled in megger usage and insulation resistance testing.

Connection Test

Connection testing is important to make sure that an appropriate electrical connection exists and to find out any indications of overheating marked by discoloration. It is vital that electrical connections are correctly set up to the Circuit Breaker to avoid and decrease overheating. Carelabs concentrates on connection testing and are skilled enough to know that aluminium connectors are plated and should not be harshly cleaned. Carelabs will fix and substitute broken aluminium connectors (lugs) to avoid future damage.

Contact Resistance Test

Usual wear and tear of contacts in the Circuit Breaker rises after lengthy use. A simple method to find out traces of deterioration within the Circuit Breaker is to calculate the resistance across each pole of the breaker. Carelabs induces a current through a CB and uses a voltmeter to find out the voltage across the breaker. By understanding the current induced and the

measured voltage, Carelabs is able to determine the contact resistance based on ohms law. Signs of irregular conditions within the CB such as corrosion and corruption of contacts are obvious if there are too much millivolt drops across the breaker. The contact resistance test is important in finding out whether or not a CB is still suitable for operation.

Overload Tripping Test

Overload tripping modules of Circuit Breakers can be checked by injecting (3*100) % of the breaker rating into every pole of the circuit breaker to establish that it will open involuntarily. The reason for this test is to make sure that the CB will work. Carelabs refers to NETA standards for trip times that are suitable for the overload tripping test. When attempting to determine tripping characteristics other than whether or not the CB works or not, it is clever to check with manufacturer’s trip curves and instruction manuals.

Instantaneous Magnetic Tripping

It is much more appropriate to find out that the magnetic feature is working or not and will trip the CB rather than determining the precise value at which the instantaneous magnetic feature works.

Benefits of Circuit Breaker Testing

Circuit Breaker Testing is vital to make sure a safe and reliable performance of the circuit:

- Quick and easy to perform on site

- Circuits can be tested on or off load

- Tests performance of whole tripping cycle

- Tests overall timing of tripping system

- Identifies need for maintenance