Carelabs is authorized provider of Electrical Installation’s Study, Analysis, Inspection, and Certification services in UAE, and offer GFCI Standard Inspection Service.

One of the most important aspects of being a home inspector is detecting safety hazards. Unsafe electrical practices are common safety hazards home inspectors will come across.

One area of the electrical inspection in particular is Ground Fault Circuit Interrupters (GFCI). OSHA 1910.399 defines a ground fault circuit interrupter, or GFCI, as “a device whose function is to interrupt the electric circuit to load when a fault current to ground exceeds some predetermined value, that is less than that required to operate the over-current protective device of the supply circuit.

Charles Dalziel first developed a transistorized version of the ground-fault circuit interrupter in 1961. Through the 1970s, most GFCIs were of the circuit-breaker type. This version of the GFCI was prone to frequent false trips due to poor alternating-current characteristics of 120-volt insulations. Especially in circuits with long cable runs, current leaking along the conductors’ insulation could be high enough that breakers tended to trip at the slightest imbalance. Since the early 1980s, ground-fault circuit interrupters have been built into outlet receptacles, and advances in design in both receptacle and breaker types have improved reliability while reducing instances of false trips.

A Ground Fault Circuit Interrupter, commonly called a GFI or GFCI, is most commonly installed on exterior outlets, or in areas where there is a water source (bathroom or kitchen sink) near the outlet. They are easily identified by two buttons in the middle of the receptacle, sometimes the buttons are coloured.

A GFCI is typically a receptacle with small buttons on it that usually say “Test” and “Reset”. It can also be built into a circuit breaker that is installed in an electric panel.

GFCI units are designed to guard the users of electrical appliances from electrocution because of dangerous ground faults or short circuits, by mechanically turning off electricity when a fault is detected. Home inspectors test the operation of GFCI’s as part of their evaluation. They may also recommend the installation of GFCI receptacles near plumbing fixtures. But they weren’t always required. GFCI wiring regulations only apply to recent wiring installations and constructions. Older homes are not obliged to install GFI’s unless they are been rewired or a new outlet is being added in a location that would require a GFCI in a new house.

As per the 2011 NEC, GFCIs are required in the following areas of the home, excluding pools, spas & boathouses.

- Required to be in readily accessible locations

- All bathroom receptacles

- All garage receptacles and accessory building receptacles

- All indoor receptacles in unfinished basements, excluding permanently installed fire alarm or burglar alarm systems

- All outdoor receptacles, excluding GFPE circuits dedicated to non-readily accessible receptacles for snow-melting or deicing equipment

- All receptacles in crawl spaces or below grade level

- All kitchen receptacles serving kitchen counters

- Receptacles within 6 ft. of all non-kitchen sinks

- Whirlpool tubs receptacles

How does a GFCI Work?

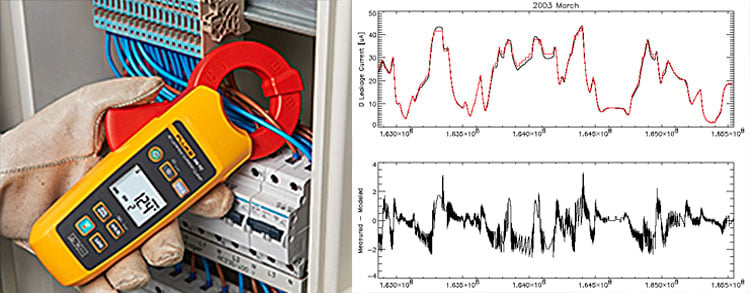

The GFCI has a sensor inside that detects variations in current that flow through the appliance that is connected to it, by comparing the current flow to the appliance and the current flow from the appliance. If there is a potentially dangerous drop off in the current, then the GFCI turns off all power by tripping a relay within it in less than one second. If a GFCI turns off your appliance, then you will have to press the reset button. A GFCI has two buttons: a test button and a reset button. If a GFCI turns off your appliance, then you will have to press the reset button. On a home inspection you should be testing each GFCI for proper operation with a GFCI 3 –prong tester.

Inspectors need to remember that they are not there to detect cite code violations, but rather, are there to make recommendations to the client if additional safety can be added or upgraded. For example if inspecting a bathroom in a house that was built in 1987, or for that fact 2007, and the receptacle is checked and is properly grounded but does not have GFCI protection, it should not be written up as a safety hazard, even though the code for GFCI protection in a bathroom went into effect in 1975. Instead, this should be expressed verbally and should be written in the report as, “for additional safety, recommend GFCI protected receptacles in the bathroom.” It is okay to recommend GFCI protected receptacles in locations that typically require them but do not currently have them.

There are three types of GFCIs

Receptacle Type

The Receptacle Type incorporates a GFCI device within one or more receptacle outlets. Such devices are becoming popular because of their low cost.

Portable Type

Portable Type GFCIs come in several styles, all designed for easy transport. Some are designed to plug into existing non-GFCI outlets, or connect with a cord and plug arrangement.

Cord-Connected Type

The Cord-Connected Type of GFCI is an attachment plug incorporating the GFCI module. It protects the cord and any equipment attached to the cord. The attachment plug has a non-standard appearance with test and reset buttons.

Ground Fault Circuit Inspection Requirements

Employers provide:

- Written description of program

- Competent person to implement the program

- Inspection and testing

- Records of test results

Inspections/Tests:

- Visual inspection of the following equipment is required:

- Cord sets

- Cap, plug and receptacle of cord sets

- Equipment connected by cord and plug

Exceptions:

- Receptacles and cord sets that are fixed and not exposed to damage

Conduct tests for:

- Continuity of equipment of grounding conductor

- Proper terminal connection of equipment grounding conductor

Frequency of tests:

- Before first use

- After repair and before placing back in service

- Before use after suspected damage

- Every three months—however, cord sets and receptacles exposed to damage must be tested at regular intervals not to exceed six months

All GFCIs shall be tested once every three months using the following procedures to make sure they are working properly and protecting the employees from electric shock.

- To test a GFCI, first plug a test-light or shop-light into the outlet, the light should be ON. Then press the TEST button on the GFCI , the GFCIs RESET button should pop-out and light should go out.

- If the RESET button pops out and the light doesn’t go out the GFCI has been improperly wired.

- If the RESET button doesn’t pop out the GFCI is defective and should be replaced.

- If the GFCI is functioning properly, and the lamp goes out. Press the RESET button to restore power to the outlet.

The GFCI will not protect you from line contact hazards (i.e. a person holding two “hot” wires, a hot and a neutral wire in each hand, or contacting an overhead power line). However, it protects against the most common form of electrical shock hazard, the ground-fault. It also protects against fires, overheating, and destruction of wire insulation.