Electric motors are utilized in a broad variety of applications, ranging from huge industrial equipment such as turbines to domestic products such as blenders.

In New Zealand, around 70% of the electrical energy generated on average is consumed by electric motors. Among the 70%, the majority of electricity is consumed by medium-sized motors, with output power ranging from 0.75 to 375 kW. These motors are widely used in industrial applications such as power pumps, compressors, alternators, rolling mills, movers, etc. Thus, the downtime costs of malfunctioning motors can amount to tens of thousands of dollars an hour.

Given their vital significance for industrial operations, maintaining the efficiency and reliability of motors is one of the most critical duties faced by maintenance engineers every day.

Care Labs offers an all-inclusive Motor Start Study and Analysis service to cater to your electric motor efficiency needs.

Cause of Inefficiency in Electric Motors:

Machines gradually lose efficiency by wear, lubricant decomposition, and alignment. Potential sources of efficiency loss are:

- High winding resistance

- Misalignment of shaft

- Improper installation or adjustments.

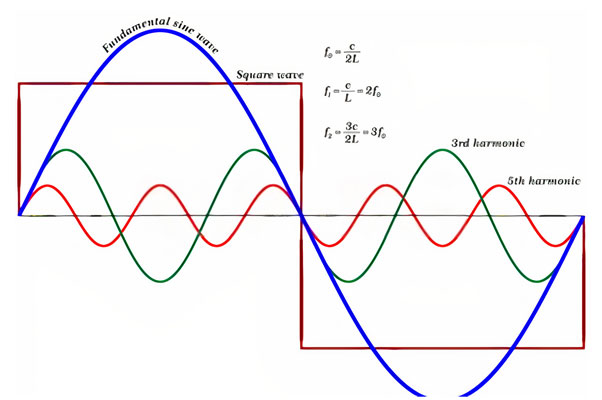

- Poor power quality

- Poor lubrication

- Heat dissipation

- Plugged ventilation slots

- Induced vibrations

- Accumulation of dust and dirt.

- Presence of moisture

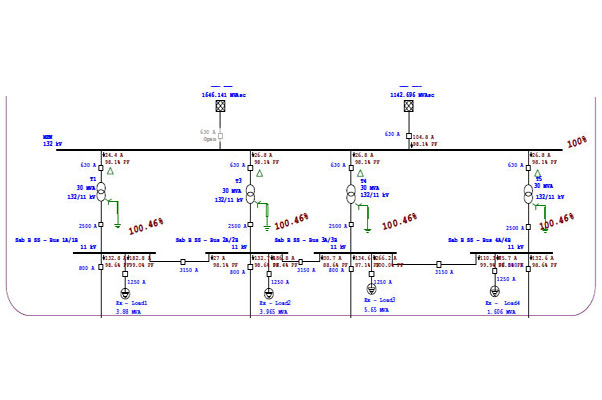

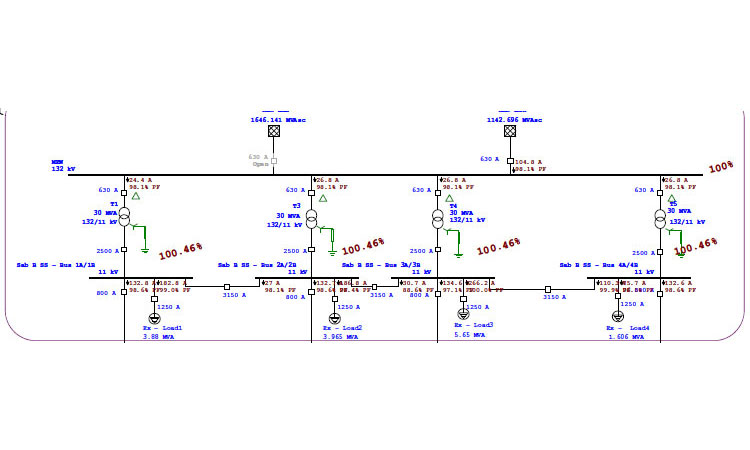

In large motors connected to the line, starting operation may cause severe disruptions to the electric motor, to the locally attached loads, and to the buses that are electrically distant from the motor’s starting point.

The motor terminal voltage should be maintained at least 80% of the rated voltage or greater while starting an electric motor. If there is a significant drop in the voltage, operating machines can exceed their torque and result in severe deceleration, or even stalling.

The voltage drop also impacts other types of loads such as electronic equipment, sensitive control units, lighting loads, etc. In such cases, a motor start study and analysis will help identify the voltage dip and acceleration time. Thus, evaluate the correct starting and running of electric motors without leading to system instability.

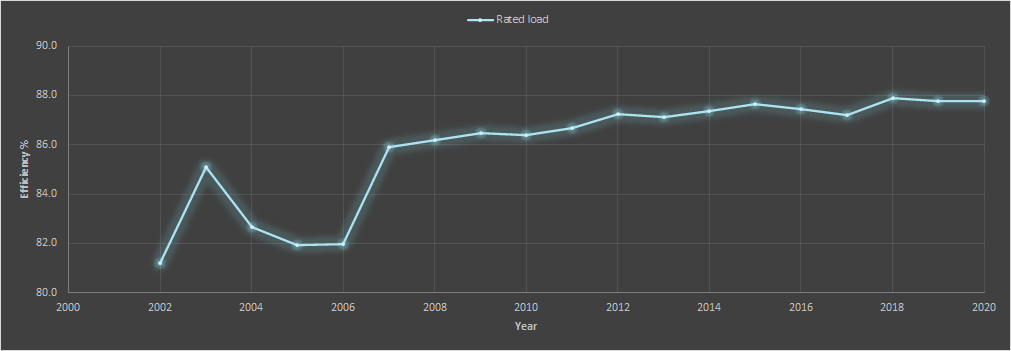

Energy Efficiency and Conservation Authority in New Zealand has provided the efficiency of three-phase cage induction motors from 2002 to 2020.

Figure. Average full load efficiency of three-phase cage induction motors in New Zealand

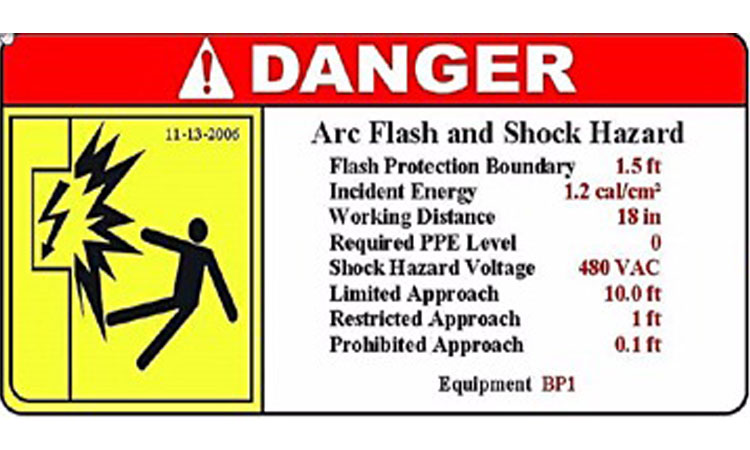

Electrical Safety Standards:

The Cabinet the International Electrotechnical Commission (IEC) has adopted in New Zealand for three-phase cage electric induction motors test method; the IEC 60034-2-1 Ed 2.0, Rotating electrical machines Part 2 1: gives the standard methods for determining losses and efficiency from tests.

Technical regulatory requirements are contained in the New Zealand Standard AS/NZS 1359.5:2004 – Rotating electrical machines—General requirements for motors—High efficiency and minimum energy performance standards requirements.

Minimum Energy Performance Standards (MEPS) were developed to remove poor-performing motors from the market. MEPS covers New Zealand’s three-phase cage induction electric motors with rated output ≥ 0.73kW & < 185kW, in 2, 4, 6, and 8-pole configurations, and voltages rated up to 1100V (AC).

New Zealand Electrical Safety Guidelines:

In the rules provided in AS/NZS 1359.5:2004, there are two distinct test methods, test method A or test method B. Both are valid test methods for MEPS.

Method A: Measured as per AS/NZS 1359.5:2004, sec 5-7. It involves precise and direct measurement of stray load losses.

Method B: As defined in AS/NZS 1359.102.1-1997 or IEC 60034-2-1 It assumes a fixed figure of 0.5 percent for additional load losses. Therefore, the required efficiency levels for Method B are higher than for Method A.

Key Benefits of Getting a Motor Analysis from Care Labs:

- Enhanced efficiency leading to increased energy savings

- Operating reliability

- Reduced losses

- Minimal vibration and noise

- Help to achieve a high-power factor.

- Reduction in operating temperatures improves motor life and reduces maintenance expenses.

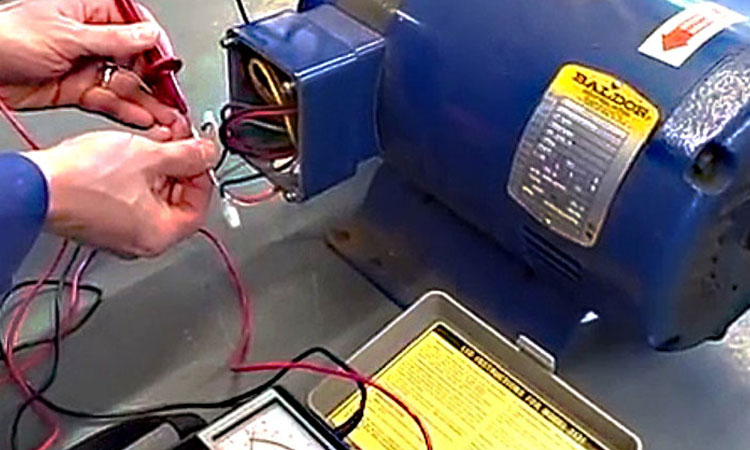

Care Labs offers motor start study and analysis to evaluate the mechanical power, speed, torque, and power quality attributes of your electric motor. Our experts carry out preventive maintenance to minimize downtime and focus on getting maximum efficiency through optimization.

Care Labs offers its services across New Zealand including Auckland, Wellington, Canterbury, Waikato, Bay of Plenty, and Otago. To get your motor start analysis, book an inspection or get a quote by contacting us! Our service representatives will reach out to you within 24 hours.