Electric motors are the key element of many industrial processes, which is accounting for almost 70% of the energy used in industries and 46% of global electricity generation.

Given its critical nature in industrial processes, the cost of downtime associated with engine failure can reach tens of thousands of dollars per hour.

Ensuring the efficiency and reliability of the motor is one of them. The most important challenge that maintenance technicians and engineers face every day. In many cases, energy efficiency can mean the difference between profitability and financial loss.

The reduction in motor efficiency leads to higher costs and higher operating temperatures.

Five Factors that Affect Motor Efficiency are:

- Conductor content

- Magnetic steel

- Thermal design

- Aerodynamics

- Manufacture and quality control

The efficiency of a motor depends on the choice of used materials for the magnetic core and windings, their working condition, and the care and precision in handling and assembly.

How to Avoid Motor Efficiency Problems?

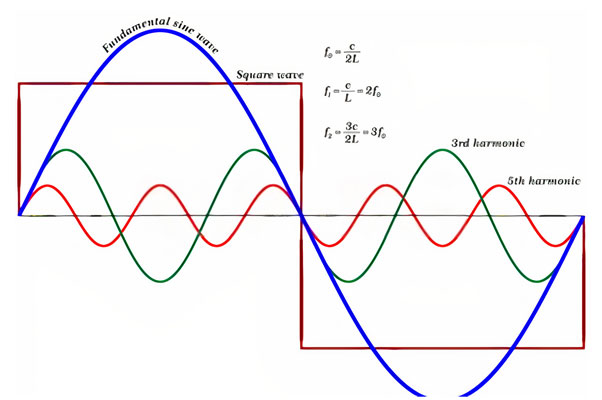

- Eddy current loss is generated by the induced current in the stator plate and can be reduced by reducing the thickness of the plate and providing good insulation between adjacent plates.

- The resistance loss can be reduced by adding more copper to the winding.

- The new simulation technology makes it possible to manufacture motors with the optimized cooling flow, reduced gaps (increased magnetic circuit efficiency), and reduced copper loss.

- A computer simulation was used to optimize the fan and shroud design to provide more effective cooling and lower noise levels.

- By considering the assembly method and paying attention to the processing method at the design stage, the increase in iron loss during the production process has been reduced to a negligible proportion.

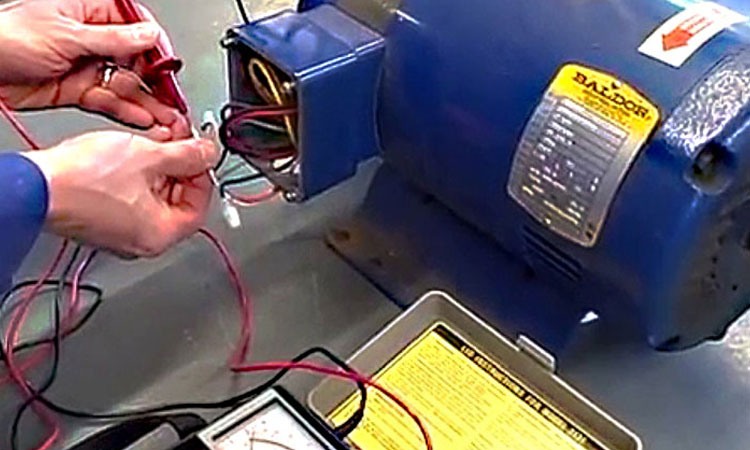

Since motors usually require a lot of power to accelerate to rated speeds, a soft starter can be used to limit overcurrent (called “starting current”) and motor torque to achieve a safer, smoother, and smoother start.

The motor start analysis protects your motor from potential damage by reducing the heat generated by frequent starts/stops, reducing the mechanical stress on the motor and its shaft, and the electrical stress on the power cable while extending the life of the motor and the entire system.

Soft starter operation:

The working principle of a soft starter is to control the amount of voltage passing through the motor circuit. This is achieved by limiting the motor torque. This in turn allows the soft starter to lower the voltage and gradually stop the voltage drop, thereby providing smooth current changes.

How Can Care Labs Help?

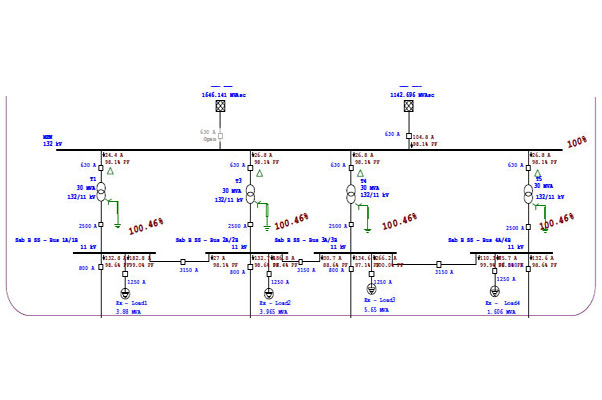

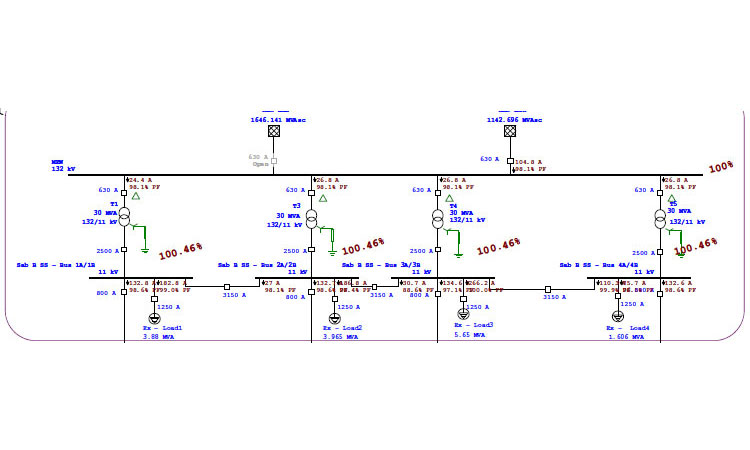

- Based on our computer model using ETAP, we can predict your plant performance and diagnose problems, and propose solutions for existing engine plants.

- We use static and dynamic models to simulate the starting characteristics of the motor, and we mainly rely on dynamic research to simulate the observed and calculated starting characteristics.

- Initially, the investigation process started at the customer site and collected current and historical data on engine performance according to NEC requirements.

- The complete system model and simulation are designed for operation using the measurement data in the ETAP software.

- Calculate the voltage drop across each feeder, bus, and expected power flow.

- Our simulation model allows us to predict the performance of new facilities, diagnose problems, and propose applicable solutions based on data and project requirements.

- The results are then evaluated according to the limits set by the IEEE standard.

- Based on the analysis performed, suggestions are given to minimize the voltage drop and acceleration problems.

Care Labs Service Benefits:

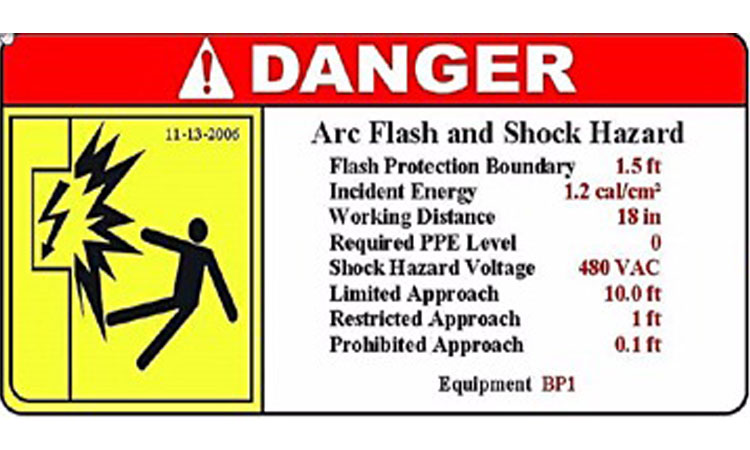

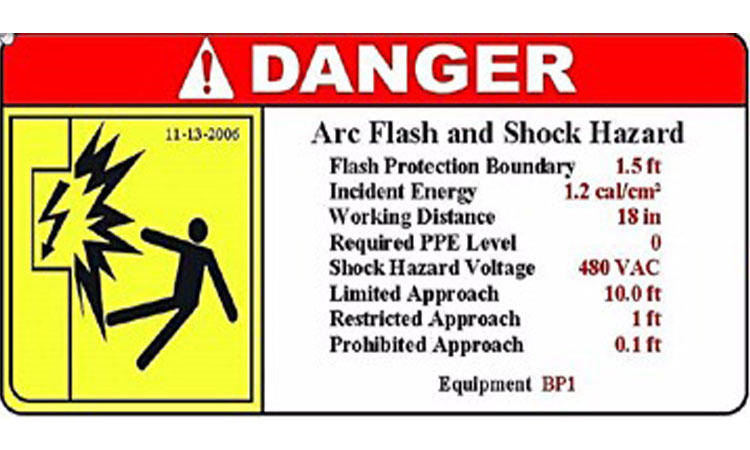

- Our team of professional engineers can help you avoid accidents, productivity losses, and determine the existence and location of potential hazards.

- National registered professional and technical personnel.

- Has extensive experience in various electrical system infrastructure, from industry to all types of commercial companies.

- Reduce the risk of expensive lawsuits due to electric shock injuries.

- A documented quality plan to ensure consistent and consistent service for your business.

- Excellent safety rating, safe work practices.

- Industry-leading customer satisfaction.

- We have highly qualified, experienced, and friendly professionals.

Performing machine efficiency and reliability audits can help your business achieve its goal. You can hire a Care Labs specialist to make your task easier and to make sure that everything in your business complies with government laws and regulations.

Care Labs offers its services across New Zealand including Auckland, Wellington, Canterbury, Waikato, Bay of Plenty, and Otago. Book your inspection or get a quote today!