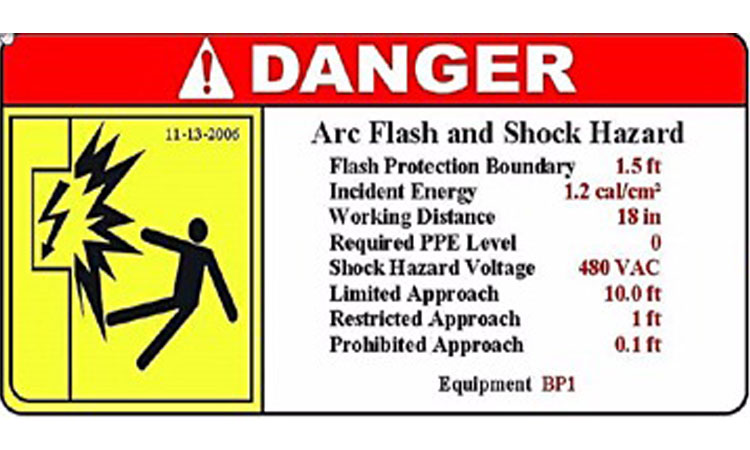

Working near electricity is dangerous, and accidents are often fatal. Since no device can provide you with 100% protection against electric shock, it is important to consider safety.

Electricity can cause harm in two ways.

First of all, electric shock (the electric current passing through your body) can cause severe burns and a potential risk of involuntary body movement. Secondly, electric arcs (release energy) can cause explosive injuries, lung injuries, ruptured eardrums, shrapnel wounds, severe burns, and blindness.

Electrical safety is an eternal topic. For electrical reasons, the manufacturing industry is likely to catch fire, especially industries that use flammable chemicals.

In service industries such as information technology, telecommunications, banking, and other enterprises, the risk of electric shock may cause business interruption and loss.

The electrical equipment you use presents a great risk in the form of equipment damage, wrong work tools, and abandoned tools pose the greatest risk when it comes to the equipment itself. The environment you work in can have a number of hazards, such as power lines, underground utilities, and excessive amounts of water.

The power supply you are using can easily be overloaded when there are many contractors on-site, make sure the outlets are not overloaded and the power supply is grounded.

So we need to take enough measures to prevent them.

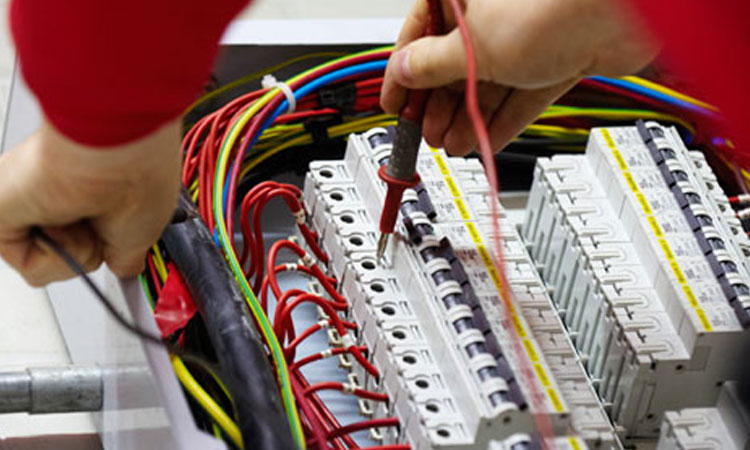

For safety reasons, additional electrical inspections should be performed at the recommended time under the guidance of a qualified electrician or electrician, usually 1 to 4 years.

Why is an Electrical Safety Audit Necessary?

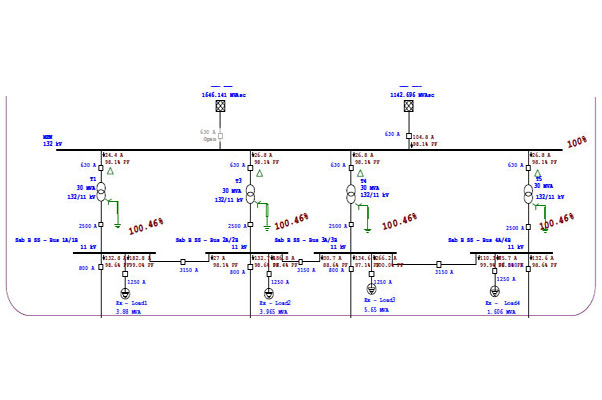

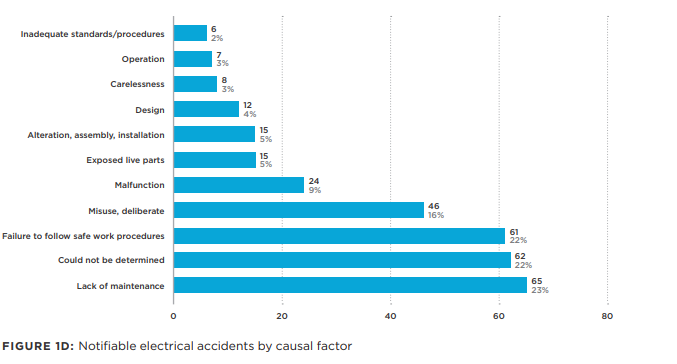

Electricity has now become the most important part of our lives, but it also brings serious risks, which may put life and property in great danger. These electrical hazards and dangers may appear in the form of electrical fires and explosions, electric shocks, short circuits, and malfunctions.

Therefore, not only important but also effective and effective management and control of these electrical hazards also take time, especially in industries where these hazards will have a greater impact and may cause huge losses.

The need to identify and eliminate potential hazards and accidents can be met through electrical safety audits. Pass the electrical safety audit to effectively create the company’s reliable safety system.

If implemented properly, it will bring many obvious benefits and help management to develop emergency preparedness plans

Benefits of Electrical Safety Audit by Care Labs:

- comply with regulations

- Higher security

- Use resources more efficiently

- Clarify electrical safety responsibilities

- The maintenance of electrical equipment must avoid hazards and ensure that the equipment continues to be used under operating conditions.

- Identify and eliminate security threats

- Ensure the durability of high-value electronic equipment (such as computers and other machines).

- Prepare dynamic reports on safety performance

- Establish a positive safety improvement cycle

- Comply with safety regulations and industry best practices.

Electrical Safety Standards and Guidelines for New Zealand:

- Electricity Act 1992

- Occupational Health and Safety Act 2015(Health and Safety at Work Act 2015)

- AS/NZS 3760: 2010 Operational Safety Inspection and Electrical Test

- AS/NZS 3012: 2010 electrical installation -demolition and construction site

Approved code of practice for demolition

Electrical safety auditing services in New Zealand is a standardized approach to evaluate potential hazards and recommend suggestions for improvement.

Care Labs provides electrical safety audit services that are conducted by experienced professionals who’ll ensure compliance with applicable standards and statutory rules and regulations.

Care Labs offers its services across New Zealand including Auckland, Wellington, Canterbury, Waikato, Bay of Plenty, and Otago. Book your electrical safety audit in New Zealand or get a quote today by contacting us!