Electric motors have broad applications in areas such as industry, business, public service and domestic appliances, powering a variety of equipment. In developed nations and large developing nations, electric motors applied in industries account for a considerable proportion of total national power consumption.

Statistics indicate that electric motors are generally responsible for about 2/3 of industrial power consumption in each nation, or about 40% of overall power consumption, which means that the electric motor system consumes almost 679 billion kWh of electric power each year.

According to estimates, adopting existing well-established energy-conserving technologies and products would result in savings of approximately 11–18%, or 75–122 billion kWh of electric power annually, which would also mean saving US $3.6–5.8 billion in electricity costs.

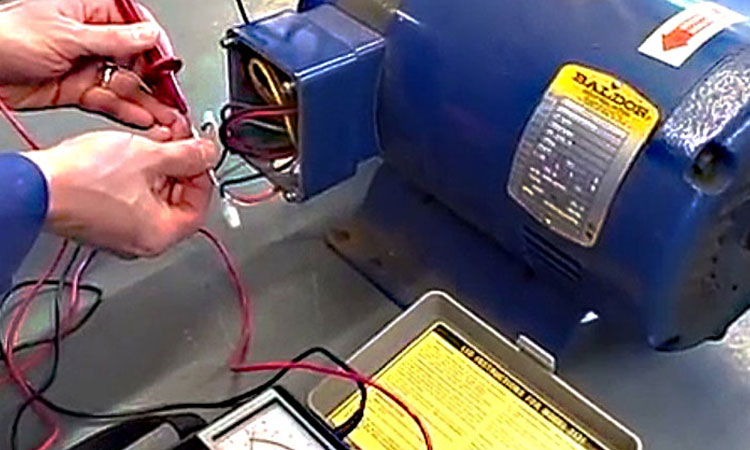

Care Labs has a series of testing methods for customers required to perform motor acceleration analysis of electric motors in accordance with a variety of national and global standards, including IEC 60034-2-1, IEEE 112B, and NOM-016-ENER.

Benefits of Applying Energy Efficient Motor:

Energy-efficient motors use less electricity, less heating loss, less noise, and longer life. Higher efficiency electric motors can lead to significant impact in productivity and sustainability of industrial process and also reduce the environmental impact by contributing to the reduction of the greenhouse effect.

Thus, if 80 percent energy efficient motor means, it can convert 80 percent of the electric supply energy into mechanical energy. The remaining 20 percent of the electric energy is lost as waste.

Although the CO2 emission per kWh of produced electricity differs from country to country, it is expected that between 2010-2030 electricity energy demanded by the electric motor system will increase from 8360 TWh/year to 13360 TWh/year, with the consequent CO2 emission increase from 6040 Metric Tonne to 8570 Metric Tonne (approximately 75%).

Testing Standards for Motor Energy Efficiency as per National/International Standards:

As a global effort for reduction of the fossil fuel usage and greenhouse gas emission are developed by national/international standards for energy of electric motors used around the world. These standards specify how to ensure motors are meeting the efficiency standards.

IEC 60034-2-1: standard on efficiency measurement low voltage AC motors methods,

IEEE 112B: standard test method for polyphase induction motors and generators

IEEE 115:2019:

This standard deals with the performance assessment of synchronous machines.

ANSI/NEMA MG1 – Motors and Generators

This standard helps users for the proper selection and application of motors and generators.

C390-98 (2005)

This Canadian Standard is similar to IEEE 112-B specifies the test methods to be used in measuring the energy efficiency of three-phase induction motors. It applies to motors rated 0.746 kW at 1800 rpm and greater.

CAN/CSA C22.2 No.100-04 – Motors and Generators

This is the Canadian equivalent to ANSI/NEMA MG1.

Mexican Motor Efficiency Testing Standard:

Mexico and Brazil have also worked for their own minimum energy efficient standard electric motors. The NOM-016-ENER- 2016 standard efficiency index of Mexico’s 1997 standard was the same as under NEMA12-9, the earlier U.S. standard for high-efficiency electric motors.

Mexico’s current standard is NOM-016-ENER-2002, whose efficiency index is the same as that of EPACT. The Mexican standard has somewhat broader applications than EPACT, covering power between 0.746 and 373 KW and vertical as well as horizontal installation. This standard took effect in March 2003. See the attached list for standard efficiency indices.

Benefits of Availing Service from Care Labs:

- Get a single point of contact for all your queries throughout the project life cycle

- Offers highly skilled electrical professionals to carry out service availed by you

- Achieve compliance with relevant regulations/standards in Mexico.

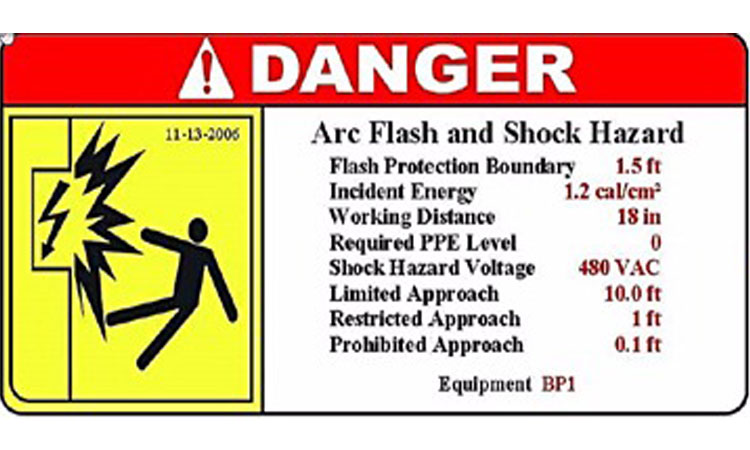

- Meet employee/staff safety demands and dedication to electrical safety

- Identify and eliminate issues of your electrical installation

- Reduce the risk of expensive litigation, penalties for the damages caused by your electrical installation

- Improve productivity of your business by reducing downtime due to electricity-related issues

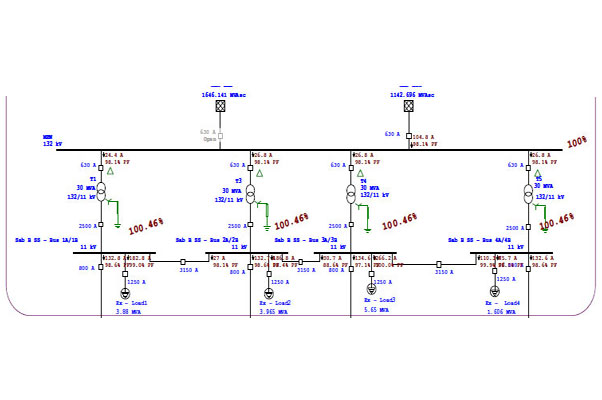

- Get a reliable and trustworthy comprehensive report about your electrical installation using industry-recognized ETAP software

- Care Labs detailed study and analysis report will assist your professionals to find any risks or general wear and tear that could affect your safety

Contact Care Labs today to speak with one of our technicians about motor start study service.