Electric motors are the key element in many industrial processes, and can account for up to 70 % of the total energy consumed in an industrial plant. As per estimation, the EMDS- electric motor driven systems account for total of 43% to 46% of all global electricity consumption, giving rise to about 6040 Mt of CO2 emissions worldwide.

By 2030, without effective and comprehensive energy‐efficiency policy control measures, energy consumption from electrical motors is expected to increase to 13360 TWh per year and CO2 emissions to 8570 Mt per year.

Based on the critical nature of business processes, the outage cost associated with failure of electric motors can be thousands of dollars per hour. Most likely your operation’s motors account for a large part of your monthly electric bill. Very often electric motors are oversized or mismatched for the loads than they are intended to serve.

To compare the operation costs of an existing electrical motor with an appropriately sized energy efficient standard motor replacement, you have to assess it in terms of operating hours, efficiency improvement levels, and load capacity.

Need for Motor Efficiency and Reliability Audit:

The main concerns of commercial and industrial consumers are the motor reliability, and their efficiency. The reliability and energy efficiency factors are directly related to the industrial operation downtime.

Therefore, motor acceleration study and its efficiency are very important for industrial users.

Motor Efficiency and Reliability:

The efficient use of electricity is not just a best practice. The energy efficiency of motor to elates the difference between profitability and financial losses. This is because electric motors consume such a significant amount of energy in industrial process, so directly they have become primary target for cost savings and maintain profitability.

Additional to identify the savings through efficiency improve and reduce natural resources dependency is driving many industries to adopt industry standards such as ISO 50001.

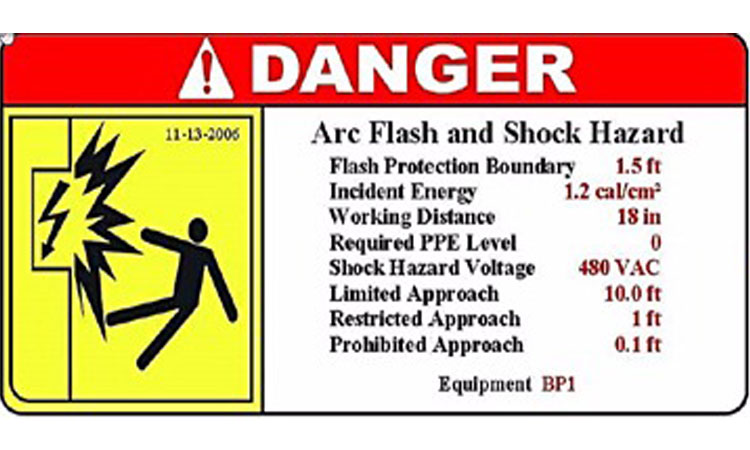

Besides motor efficiency, there are other important operational factors taken into account that decides an efficiency of motor, such as motor reliability, protection, starting torque, and torque-speed capability in modern industries. Reliability assessment of EMDS is essential. Safety is a major concern in such applications, and it is directly relating to reliability.

Process of Motor Efficiency and Reliability Audit:

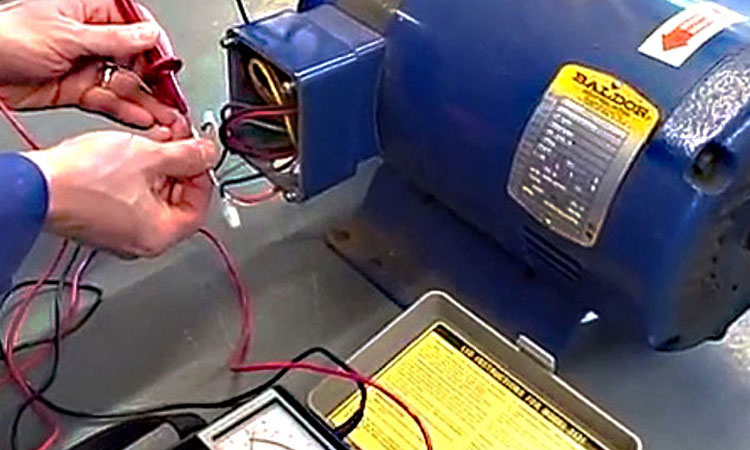

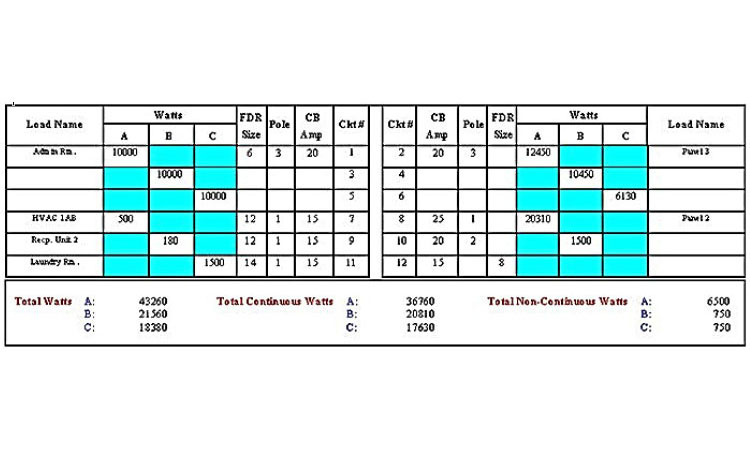

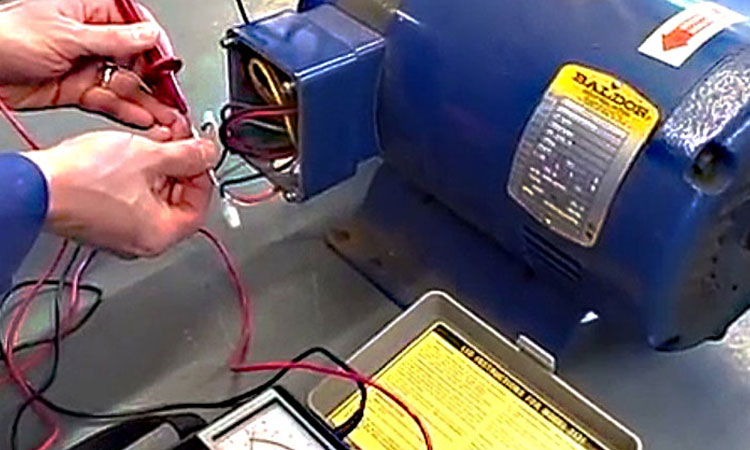

Preliminary tests are performed – These include basic measures of motor performance, current and voltage levels, power, and resistance.

To resolve inefficiency issues, perform motor specific tests as follows:

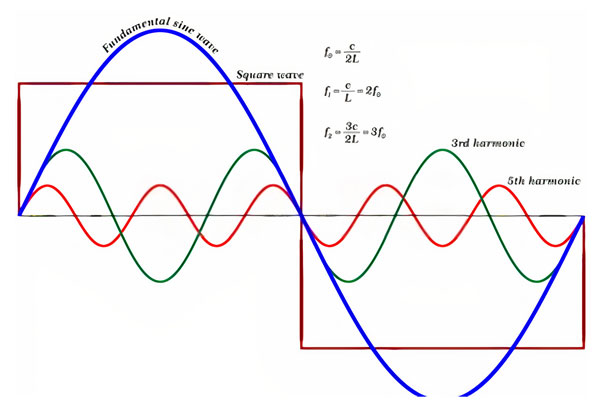

- Core loss Test to evaluate any inherent energy loss/ abnormal power losses

- Hipot Test to determine the efficiency of cable insulation

- Surge testing to detect and predict motor burnout/ failure

- Evaluate the performance of insulation by performing the Megger test

- Performing voltage drop test to evaluate the quality and efficiency of operation.

A comprehensive motor efficiency and reliability audit developed from the facts, figures, observations, and results obtained from performing the above tests. Further, the identified inefficiency issue is identified, isolated and preventive measures are applied.

Key Benefits of Performing Electrical Motor Efficiency and Reliability Audit:

- Improved efficiency resulting in higher energy savings

- Reliability of operation

- Lower operating temperatures increase the life of the motor and reduce maintenance costs.

- Bring down noise and vibration

- Helps gain high power factor and Power factor correction

- Reduced loss

- Save energy, tariff optimization, and billing analysis

- Reduce operating costs

- Minimize downtime

- Increase productivity

- Motor management plan

- Rewinding and use of energy-efficient motors

- Improved performance of pumping systems, fans, and blowers

Benefits of Availing Service from Care Labs:

- Get a single point of contact for all your queries throughout the project life cycle

- Offers highly skilled electrical professionals to carry out motor start analysis service availed by you

- Achieve compliance with relevant regulations/standards in Mexico.

- Meet employee/staff safety demands and dedication to electrical safety

- Find and eliminate issues of your electrical installation

- Reduce the risk of expensive penalties for damages caused by your electrical installations

- Improve productivity of your business due to electrical safety related issues

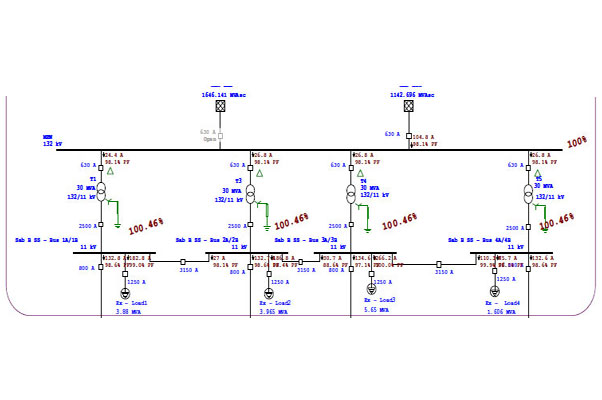

- Get a reliable and trustworthy comprehensive report about your electrical installation using industry-recognized ETAP software

- Care Labs detailed study and analysis report will assist your professionals to find any risks or general wear and tear that could affect your safety

Hire professionals from Care Labs, move towards energy-efficient and environment-friendly industrial operations.

Contact us to know more or to avail of our services.