Importance of Arc Flash Hazard Analysis and Mitigation Methods

Electrical arcs can emerge when a gas is subjected to a voltage greater than its insulative qualities. An arc emerges when the voltage is strong enough to ionize the air between the conductors. Ionized air becomes a good conductor, allowing current to flow. The current generated by air ionization generates heat and bright light in the air. This heat causes the ionized air to rise, resulting in an arched shape of current, hence the name of the phenomenon. An arc flash can generate temperatures of up to 20,000 degrees Celsius.

Arc flash hazards are dangerous to both property and people. Some of the business effects of arc in flash include:

- Direct costs include medical treatments, rehabilitation, and worker compensation, as well as the cost of accident investigation and production loss.

- Legal and judgment costs, litigation costs, fines, insurance premiums, repair costs, and replacement worker costs are examples of indirect costs.

- Negative consequences cost your personal reputation, your ability to compete in the labor market, and the possibility of criminal charges.

- Most customers reject companies with high incident rates, resulting in lost business opportunities and even the loss of the license to perform electrical work.

- Arc-related mishaps Flash tends to leave an impression that is difficult to forget, resulting in missed opportunities and lost profits.

Arc Flash Hazard Causes:

- Using the test probe on the wrong surface

- Inappropriate tools, installation, and work methods

- Making use of faulty electrical components

- Insulation damage or equipment gaps

- Disconnect panel interference

- Electrical equipment dust or corrosion

- Improper circuit breaker and switch maintenance

- Exposed live parts or frayed connection

- High voltage cables or constant power supply

- Electrical equipment dampness

Methods of Arc Flash Hazard Mitigation:

- Deactivating Electrical Components:

It reduces the risk of potential hazards to the greatest extent possible. Working on energized equipment should be avoided, and extra care should be taken when testing the equipment after it has been de-energized or re-energizing it. Remote tracking technology is used to keep circuit breakers away from arc flash boundaries, which could endanger the worker operating them.

- Make Use of Low-Risk Technology:

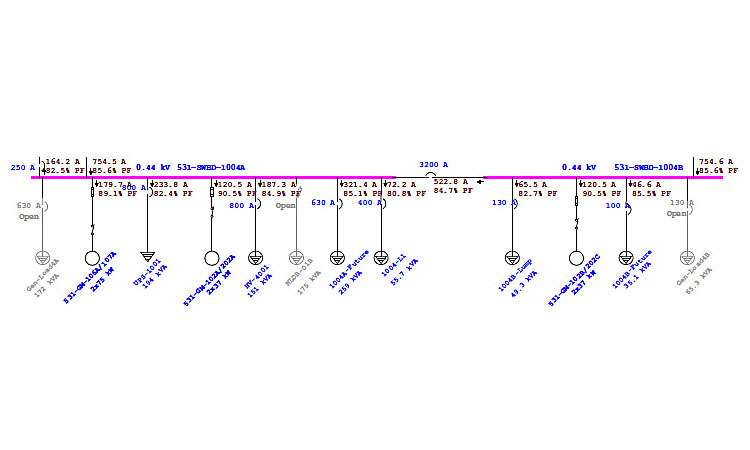

Arc flash analysis and power system studies are performed to identify the risks associated with short circuits and protective device coordination. To keep people and property safe, use low-risk technologies such as remote racking equipment.

- Redesign Electrical and Control Systems:

Ensure that the appropriate level of PPE (personal protective equipment) is available in accordance with the arc flash hazard category. Engineering equipment and processes are being redesigned in order to reduce risks. Circuit breakers and energy distribution systems are configured to reduce incident energy.

- Reduce the Available Fault Current Level:

Non-current limiting breakers will allow industries to reduce the amount of available fault current. During maintenance, these devices can be used with an open tie. By reducing available fault current, the opening tie-in between dual power feeds during maintenance reduces arc flash hazards. Current limiting reactors can be used to create a bottleneck in the flow of electrical current, thereby eliminating current during arc faults.

- Shift the Blast Energy:

Promote arc-resistant materials. Arc-resistant switchgear uses sealed joints, top-mounted pressure relief vents, and reinforced hinges to channel arc flash energy and heat through ducts to an unoccupied location. Care Labs performs complete arc flash analysis. To update your safety program, experts assess arc flash dangers. Care Labs can discover and deploy contemporary arc flash risk prevention methods. Care Labs can research and implement cutting-edge arc flash danger prevention technologies. ETAP software is used in care labs for research and analysis.

We employ crew members in a variety of locations to ensure that our experts are close by in normal or emergency scenarios. We quickly obtained ISO 9001:2008 certification and a loyal clientele. In Athens, Thessaloniki, Patras, Larissa, and Heraklion, Care Labs analyses arc flashes.

Share Post

Related Posts

-

Load Flow, Short Circuit, and Relay Coordination in Power System Analysis

-

Importance of Arc Flash Hazard Analysis and Mitigation Methods

-

Arc Flash Analysis in Greece: A Step-by-Step Guide

-

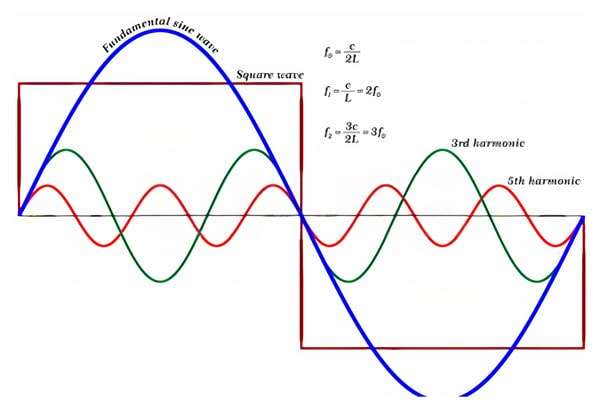

Power Quality Working Principles in Greece

-

Harmonic Analysis in Power System in Greece

-

How to evaluate efficiency and dependability of commercial motors?

-

Test and Verify Electrical Motor Efficiency in accordance with Greek Guidelines

-

How to Conduct Power Quality Analysis in Greece

-

Why is Harmonic Analysis and Study Important for Greek Businesses?

-

The Importance of Load Flow and Short Circuit Analysis for a Greek Business