Arc Flash Analysis in Greece: A Step-by-Step Guide

When a gas is exposed to a voltage greater than its insulation properties, electrical arcs form. The arc is started when the voltage is high enough to ionize the air between the conductors. When gas is ionized, it becomes a good conductor, allowing current to flow and producing the arched-shaped current known as arc flash. An arc fault is an unintentional discharge of electricity that causes.

- Arc flash high temperatures cause blinding light and deafening noise.

- An arc blast is a high-pressure wave capable of ejecting molten metals and shrapnel.

- Toxic fumes

Arc flash hazards can be devastating to industries and electrical infrastructure. Commercial losses caused by arc flash hazards include the following.

- Additional costs for medical treatment, rehabilitation, and worker compensation, as well as the cost of accident investigation and production downtime.

- Litigation-related legal costs and judgments, fines, insurance premiums, repair costs, and replacement worker costs.

- Negative impact on the company’s reputation and name.

- Loss of business opportunities due to a history of accidents, which may result in the cancellation of an electrical license.

Electrical Arc Flash Causes:

- Conductor insulation that has failed

- Live parts that are exposed

- Human negligence

- Improper switch and circuit breaker maintenance

- The presence of water close to the equipment.

- Disconnect panels that are obstructed.

- High-voltage cables

- Electrostatic discharge

- Broken tools and equipment

Arc Flash Analysis Procedure:

Arc flash hazards can occur anywhere there is high voltage or low voltage high current switching.

Step 1: Determine the Risk of Arc Flash:

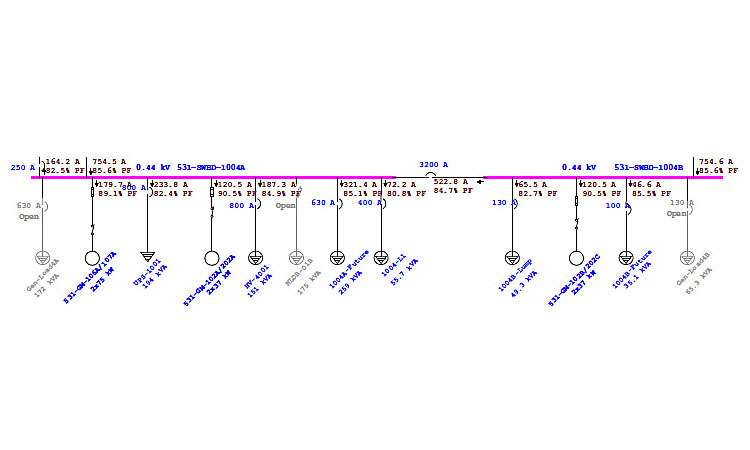

- Conduct an arc flash/fault study or analysis, which includes data collection, power system modeling with software, short circuit analysis, overcurrent protective device coordination study, arc flash analysis, and arc flash evaluation.

- Determination of the likelihood of an arc flash event exposing a worker

Step 2: Address the Risk:

- Reducing worker exposure to arc flash hazards by interacting only with de-energized equipment

- Automated systems should be used instead of manual ones.

- Protect workers from hazards by installing physical barriers between them and energized equipment.

Step 3: Engineering Control:

- Reduce incident energy by lowering fault current.

- Systems for detecting and suppressing arc flashes.

- Switching and remote controls

- Switchboard upgrade/modification

- Setup of fixed circuit breakers

- Insulation for bus bars

- Replacement of blown fuses

Step 4: Administrative Controls:

- Labelling switch rooms, plants, and other pertinent locations to identify incident energy levels.

- Arc boundary labeling

- Recording arc flash information and diagrams

- Ensuring safe policies and procedures to limit exposure.

- Putting incident energy and PPE levels into action

Step 5: Personal Protective Equipment (PPE):

- PPE, despite being the least effective, may reduce the severity of an injury but does not prevent it. The appropriate personal protective equipment (PPE) is chosen based on the incident energy levels.

Care Labs can provide a solution to all your arc flash-related hazards. Professionals who are well-trained and experienced can identify potential arc flash hazard risks and recommending appropriate mitigation and control methods to ensure the safety of your people and property.

Benefits of Care Labs Service:

- More secure power systems in accordance with government standards and guidelines

- Fully integrated power systems save time and money.

- Create a more secure working environment.

- Provide quick alternatives in an emergency.

- Expand safety margins.

- Save time by generating arc flash labels and work permits automatically.

- Avoid potential fines and legal fees.

Care Labs has crew members deployed in various locations, ensuring that our specialists are nearby in the event of a routine or emergency. Care Labs has quickly established itself as an ISO 9001:2008 certified organization and has amassed a reputable client base with positive feedback.

Care Labs offers arc flash examination and analysis services in all major cities, including Athens, Thessaloniki, Patras, Larissa, and Heraklion.

Share Post

Related Posts

-

How to Conduct Power Quality Analysis in Greece

-

Power Quality Working Principles in Greece

-

The Importance of Load Flow and Short Circuit Analysis for a Greek Business

-

Test and Verify Electrical Motor Efficiency in accordance with Greek Guidelines

-

How to evaluate efficiency and dependability of commercial motors?

-

Arc Flash Analysis in Greece: A Step-by-Step Guide

-

Load Flow, Short Circuit, and Relay Coordination in Power System Analysis

-

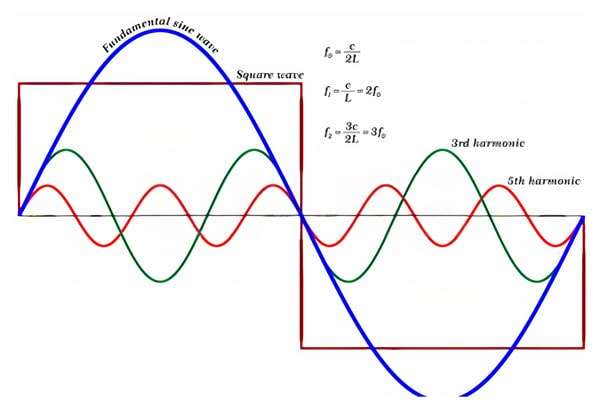

Why is Harmonic Analysis and Study Important for Greek Businesses?

-

Importance of Arc Flash Hazard Analysis and Mitigation Methods

-

Harmonic Analysis in Power System in Greece