How to evaluate efficiency and dependability of commercial motors?

Improving energy efficiency is the cleanest, cheapest, and quickest way to get reliable power. Motors consume approximately 46% of total electricity consumed and 69% of total energy consumed in the industrial sector. Energy consumption is one of the most pressing issues confronting many industries. The main concern that needs to be addressed is the poor design and improper use of electricity. Poor design and improper use are the primary causes of high electric bills and struggles to meet the excessive demand for power. Most motors operate at 50% to 100% of the rated load, while the maximum efficiency is 75% of the rated load, which begins to decline with age. After 50% load, the efficiency of an electric motor tends to decrease automatically.

Four Factors Influencing Motor Efficiency:

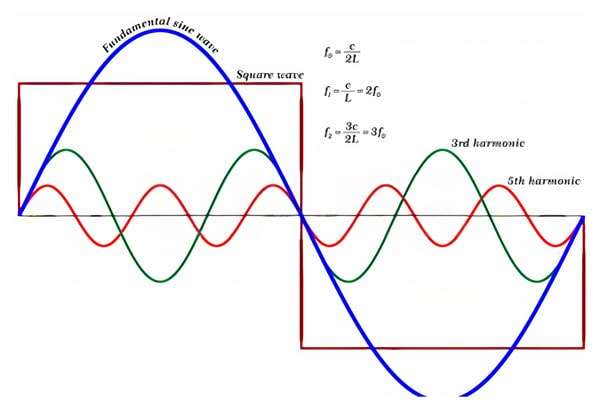

Poor power quality has a direct correlation with motor performance: transient, unbalance, sags, swells, and harmonics can cause critical damage and sometimes malfunction.

The effect of torque on efficiency and overall performance: when a motor generates rotational force to drive a mechanical load at the rotating shaft’s rated speed. The electric motor operates at torque speed at the rated frequency, ensuring dependable operation. Torque measurement provides a direct indication of the condition of the electric motor.

The electric motor running data and its expected performance: Operating the motor at mechanical overload causes stress to motor components such as the coupling, bearing, and insulation, which reduces efficiency and leads to malfunction or premature failure.

Bottom line direct effect of motor efficiency: The first step in predictive and preventive maintenance is to collect baseline data.

75% of industrial motor failures result in 1-6 days of plant downtime per year. Out of 75% of motor failures, 90% occurred within less than a month of warning, with 36% occurring within a day of warning. To avoid motor failure and malfunctioning issues Regular assessments, analyses, inspections, and audits can assist you in mitigating all electrical motor problems and improving motor efficiency and reliability.

Stats on Increasing Motor Efficiency:

Increase the efficiency of an induction motor by 68% over a 53-year period (1960 to 2013). Induction motor energy efficiency has improved over the years (data of 45 kW, 4p design motor). Care Labs audits electrical motor efficiency and reliability for a variety of commercial facilities and industries. We inspect and diagnose problems, assisting you in reducing losses and improving motor efficiency. Our goal as skilled and experienced technicians is to provide quality services to our clients.

Advantages of Using Care Labs Services:

- Is always accountable for our work.

- Offer excellent customer service.

- Prompt responses to your chats.

- Having a qualified and trustworthy electrician elevates our team.

- Understanding of Greek Standards.

- Make an appointment that works with your schedule.

- Provide you with a digital report detailing every detail for your satisfaction.

Procedures for Conducting Electrical Motor Efficiency Audits:

- Prior to beginning the audit, we gather all documents related to the site for research purposes.

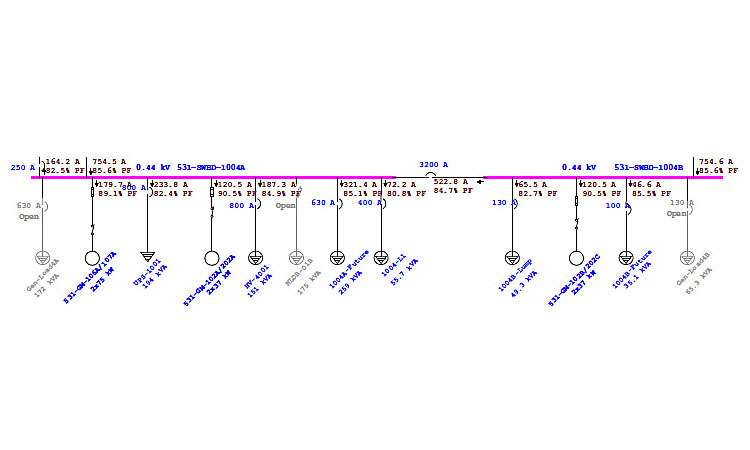

- To improve your standing, create a one-line diagram and an inspection checklist.

- Continue the audit with the electrical motor inspection checklist.

- Following the completion of the checklist, technicians perform electrical motor testing and inspection.

- Gather electric motor inspection results.

- Ensure that there are no problems with load flow or power quality.

- If any problems are discovered, our technician will ensure that they are resolved.

- Confirm that your motor efficiency meets national standards.

- Provide you with a digital format report and safe work recommendations.

Care Labs provides motor acceleration analysis to ensure that the motor performs well under high-rated load conditions and increases productivity (by mitigating the losses). Loss reduction also improves motor reliability.

We offer motor start analysis services in all major cities, including Athens, Thessaloniki, Patras, Larissa, and Heraklion. Contact Care Labs for more information and a quote on commercial electrical motor efficiency auditing.

Share Post

Related Posts

-

How to Conduct Power Quality Analysis in Greece

-

Power Quality Working Principles in Greece

-

The Importance of Load Flow and Short Circuit Analysis for a Greek Business

-

Test and Verify Electrical Motor Efficiency in accordance with Greek Guidelines

-

How to evaluate efficiency and dependability of commercial motors?

-

Arc Flash Analysis in Greece: A Step-by-Step Guide

-

Load Flow, Short Circuit, and Relay Coordination in Power System Analysis

-

Why is Harmonic Analysis and Study Important for Greek Businesses?

-

Importance of Arc Flash Hazard Analysis and Mitigation Methods

-

Harmonic Analysis in Power System in Greece