Electrical switchgear is the most valuable element in an electrical system because it ensures and maintains the electrical supply for industries.

Why switchgear is needed?

Switchgear protection has a crucial role in the modern power system network. From power generation to distribution the switchgear has a tremendous role in running the electrical appliances in a streamlined manner and protects the equipment from overload short-circuit damage.

Switchgear can bear voltage up to 1,100 kV and supplies to electrical motors and machines in the industry. Due to the high voltage, it poses a risk of causing an accident to the person who handles the switchgear.

So it’s essential to make sure that workers are adequately trained on the safety procedures while they working with electrical switchgear.

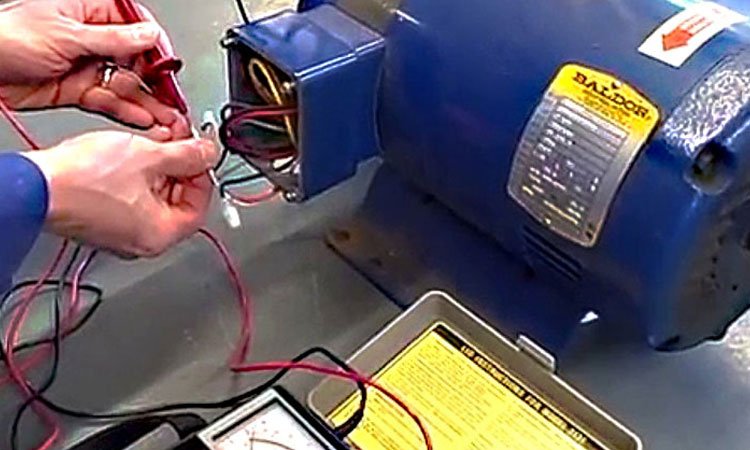

Electrical switchgear risk assessment‘s done by thermal imaging to assess the current state of the system and it helps to predict failures before they occur.

Care Labs is a provider of electrical installation’s study, analysis, inspection, and certification services.We offer a detailed electrical switchgear risk assessment service.

Electrical Switchgear Risks May Occur:

- Due to the lack of maintenance

- Overstressing of switchgear

- Contacts are directly hooked into the movement of the operating handle by the operator

- Absence of anti-reflex control handles

- Inadequate means of protection against fire

- Limited access and outlet

Safety-related risk assessment includes:

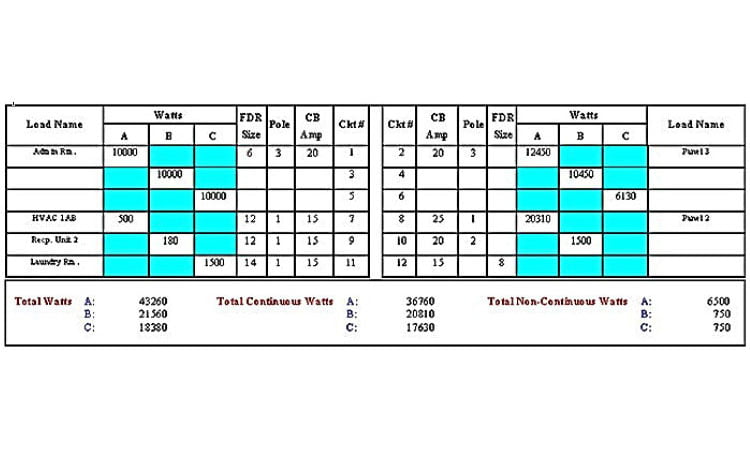

- By analyzing the limits of switchgear assembly like design and type of switchgear, rated values ambient conditions, cable testing, etc.

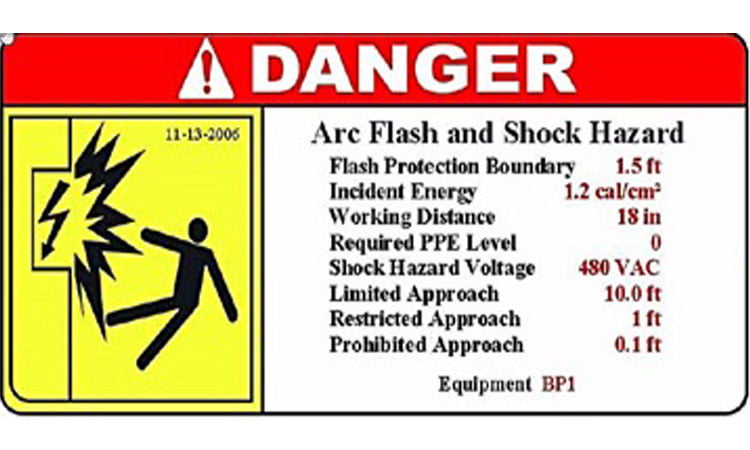

- By the examination of the associated hazards like electric shocks, arc faults, electromagnetic, etc.

- The risk estimation considers the intensity of harms and their probability of occurrence

- The Final evaluation is carried out to determine whether the risk has been achieved or a risk reduction through further measures is required.

Some common electrical accidents include:

Electrical Shock and Burns

When a person comes in contact with a wire or a location with an electrical current, they can be shocked. It is impossible to determine whether the terminal or conductor is live or off without proper electrical testing devices. A blast wave can throw a worker across space, causing injuries.

Electrical burns occur when the present travels through your body. The electric current kills human cells;it may lead to paralysisor even death.

Fire and Explosions

Medium voltage equipment that’s utilized with oil circuit breakers or oil mini sub-stations can cause fires. Excessive flow of current can cause explosions that lead to damage property and hurt workers.

Mechanical Hazards

Electrical switchgear is liable for powering electrical motors, rotating machines, and electrical moving parts during a factory.

Accidental switching of the switchgear happens when the security guards aren’t observing when switching off the switchgear.

Classifications for Switch Gears on ANSI And IEEE Standards:

Low-voltage: up to 600V

Medium-voltage: between 600V and 69 kV

High-voltage: between 69 kV and 230 kV

Medium-voltage switchgear is assessed by the utmost voltage it can service. Switchgear with 15 KV (max voltage rating) is commonly applied at various actual voltages including13.2 kV, 12.47 kV and 14.4 kV.

The switchgears can be used in commercial, industrial, and institutional MV distribution system, its main functions are

- Switchgears provide sufficient segmentation of the MV system to scale back the extent of circuit outages during on cables and power stations.

- Switch gears help within the distribution and carriage of load and overloads during maintenance and repair of various electrical connectors.

- It helps to identify and solve various types of faults and connection failures; moreover, it minimizes the damage and ensures safety.

While using the switchgear you must be aware of the risks and manage to ensure the safe operation and minimize the risk of injury. A electrical switchgear risk assessment in the US deals with identifying and taking sensible and proportionate measures to regulate the risks in your workplace.

The physical body may be a good conductor of electricity. However, coming into contact with a medium or high voltage electrical flow can cause fatal injuries or maybe death.

From this assessment, it is able to identify the process you must to make sure that the equipment and systems are being operated safely.

The switchgear is manufactured to international standards, like IEC 62271 series where design, construction, and testing requirements rule out hazards.

Although IEC standards for HV products focus primarily on electrical safety, they do not explicitly link the requirements to the hazards of a product.

Care Labs provides a reliable and professional service for testing and inspection of all your electrical needs.

We offer our services in California, New York, Illinois, Ohio, Texas, New Jersey, Pennsylvania, Georgia, Washington, Florida, Massachusetts, Michigan, North Carolina, New Mexico, Virginia, and all the major states and cities in the United States of America.

Contact us to get your electrical switchgear risk assessment today!