In this modern era, whereas everything is connected to power, we need to look into quality of power as well. Hence, poor power quality issues can and will affect the productivity, performance of machines, and electrical bills.

Usually, management of the company tends to focus on the mechanical problem often because they are not having enough knowledge about electrical power quality issues, or how to solve them.

Care Labs is providing electrical study, inspection, testing, calibration and certification services for electrical projects. By hiring a professional from Care Labs you can ensure that the quality of power is up to code with NEC regulations.

Electrical power quality testing parameters

Power quality analyzer measures and test the following parameters using cloud analytics to diagnose failure of heater, motor as well as issue of line such as harmonics, unwanted signals, surge, sag and swell, etc…

Care Labs testing parameters for power quality analysis

- Power factor

- Reactive non-working power and Active working power.

- Average 3rd phase voltage and 3rd phase current.

- Current and voltage power quality harmonics distortion.

- Report phase imbalances.

- Cumulative active and reactive energy.

A recent survey of NFPA 70 shows that the United States lost revenue of 188 billion dollars in just one year due to problem faced with the quality of power. These issues need to be diagnosed to ensure that this doesn’t happens again and again.

Steps taken by Care Labs for power quality analysis

Care Labs power quality analyzer helps you to analysis the quality of power you are using in your company. While performing power quality analysis we follow below mentioned steps:

- Our aim of the survey is to utilize report during survey.

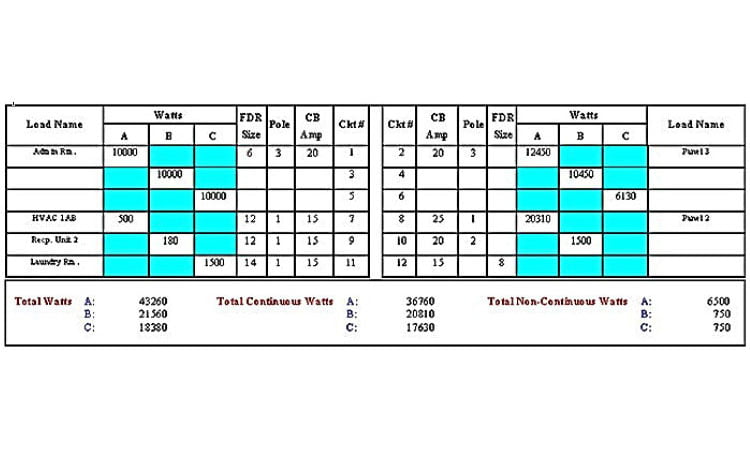

- Collect one-line diagram of the site.

- Analyzer need to connected end of the main breaker.

- Drill down distribution system by following one liner.

- Obtain data at source.

- Print out digital picture of survey, can be useful at data study.

- Analyze that there is no any harmonics, transient, sags and swells in the system.

The vast majority of motor failures in the whole US are somewhere due to bad power quality, which need to improve.

In electrical systems more than 80% are going through a breakdown in industrial plants due to poor power supply quality, which can be easily identified and diagnosed by our Care Labs professional and ensure everything works well without any interruption or disturbance.

In commercial places, issues faced by employees are on the electrical system, like elevators, air conditioners, appliance and machine breakdown, and the typical action taken by plant manager are expensive instrumentation and highly paid consultants to figure what’s going on.

Care Labs always show their responsibility to their clients and help you to analyze power quality analysis and take action to provide the best.

Using the right solution is always better than an easy and expensive quick fix, which is needed to be avoid during diagnosing the issue, hiring a Care Labs technician can help you to avoid easy and expensive quick fix mistakes.

We offer our services in California, New York, Illinois, Ohio, Texas, New Jersey, Pennsylvania, Georgia, Washington, Florida, Massachusetts, Michigan, North Carolina, New Mexico, Virginia, and all the major states and cities in the United States of America.

Contact us to get an appropriate information regarding Care Labs power quality analysis services and how it works for your company.

The Importance of Relay Coordination in Power System

Introduction Relays are protective elements that help control faults in a power system. Proper relay coordination helps isolate the fault sections from healthier sections in a power system. Being a fundamental part of ensuring reliability and operational continuity, the strategic configuration of protective relays is imperative in the design of a power system. One way […]

Which of these Facts About Arc Flashes are True?

Introduction In electric hazards, arc flashes are among the most dreadful threats. Despite their criticality, many myths surround arc flashes. Although IEEE and NFPA continuously strive to enhance awareness, five to ten arc flashes happen in the USA daily. We, at Care Labs understand the importance of maintaining a healthy electrical infrastructure. To help companies […]