The cause of an arc flash can be minor injuries, third-degree burns, and potential death as well as other harms too, including hearing loss, nerve damage, and cardiac arrest. Performing arc flash analysis can help you to identify the arc flash energy available at specific electrical systems that employees would be exposed at the duration of “interacting with” the electrical equipment at the workplace.

What Care Labs do?

Care Labs performs arc flash analysis for study and safety purposes, it helps facility employees to identify the danger level you are interacting with and how you can minimize it.

Care Labs deliver workplace electrical compliance services, including testing, calibration, safety inspection, study and analysis, and thermography.

Why we do arc flash analysis?

We live in a world where demand for high-efficient electrical equipment rapidly increasing. Interacting with more equipment also increases the risk of exposing the workers to numerous hazards, the uglier consequences are arc flash or arc blasts. An arc flash incident can be the reason for emotional and financial effects, which can be catastrophic. To avoid these hazardous incidents commercial industry or company prefers arc flash analysis.

To avoid financial losses, performing an arc flash study is the best choice, otherwise, it can also cause equipment to destroy and damage.

Arc flash study

It is an engineered incident energy analysis to establish a safety protocol for electricians and electricity interacting person.

A protocol such as wear proper level PPE based on arc hazards boundaries is defined by incident energy calculation.

It is necessary to understand the function and the” behind the scenes” details of an arc flash analysis.

Care Labs provide complete arc flash hazard study and analysis:

- We provide you full, on-site assessment.

- Next to go, arc flash modeling.

- Analysis of the equipment linked with fault current.

- Using a one-line electrical model diagram, clear the coordination of your system.

Services provided by Care Labs are handsomely effective for the electrical system, and even our professionals are members of IEEE, NFPA, and IEC which are standards of arc flash studies.

Standards and Regulations

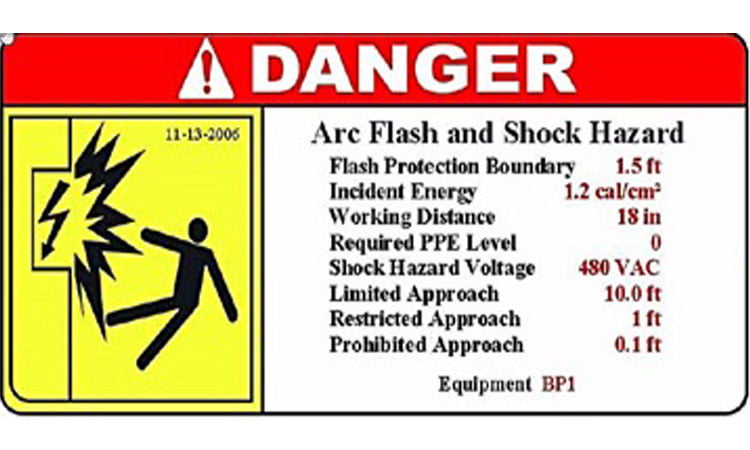

The 2002 edition of National Electrical Code (NEC) 110.16 Arc-Flash Hazard Warning: To install arc flash warning labels on industry control panels, motor control centers, panelboards, and switch-board that are required examination, adjustment, servicing, or maintenance while energized.

The 2004 edition of NFPA 70E 110.8(B) Working On or Near exposed Electrical Conductors or circuit parts that are or might become energized.

Care Labs steps to perform arc flash analysis

i. Acquire existing as-built documentation or collect data and determines modes of operation. Collected data should be the facility’s power distribution system, including a one-line drawing. This mode of operation is used to study the worst scenarios that may lead to arc flash or arc blasts.

ii. Engineering analysis of the data: Once Care Labs completed the first step, a short circuit analysis followed by a coordination study is performed. A short circuit helps to determine the magnitude of current flow, and calculate incident energy.

iii. Protective device coordination: After completing the arc flash analysis, we discover category 4 PPE will be required. This coordination has been done to ensure that selection and arrangements limit the over current situation, under IEEE standards.

iv. Arc flash calculation: In this step, we determine incident energy and arc flash protection boundaries, we can calculate incident energy by above (ii) and (iii) steps.

v. Arc flash study and analysis report: Upon completion of the calculation, we will prepare your digital format arc flash report. The report has mentioned every detail of our survey including a one-line diagram.

vi. Label installation: Creating and installing arc flash warning labels is our final step. Details mentioned in the label comply with NEC, NFPA, and OSHA std.

The industry that utilizes high electrical power has always a major chance of arc flash hazards, but we can categorize it as manufacturer, operational, and IT.

Moreover, commercial, institutional, and industrial electrical systems are most haunted by arc flash hazards, Care Labs can help you to analyze the risk by performing arc flash analysis and assist you to save from future financial expenses.

Care Labs provides you services like electrical safety inspections, electrical system design simulations, power systems study & analysis and arc flash study & analysis, by following guidelines of NEC, NFPA, and OSHA std. in the United States.

We offer our services in California, New York, Illinois, Ohio, Texas, New Jersey, Pennsylvania, Georgia, Washington, Florida, Massachusetts, Michigan, North Carolina, New Mexico, Virginia, and all the major states and cities in the United States of America.

Contact us today to get your company infrastructure inspected for arc flash.

The Importance of Relay Coordination in Power System

Introduction Relays are protective elements that help control faults in a power system. Proper relay coordination helps isolate the fault sections from healthier sections in a power system. Being a fundamental part of ensuring reliability and operational continuity, the strategic configuration of protective relays is imperative in the design of a power system. One way […]

Which of these Facts About Arc Flashes are True?

Introduction In electric hazards, arc flashes are among the most dreadful threats. Despite their criticality, many myths surround arc flashes. Although IEEE and NFPA continuously strive to enhance awareness, five to ten arc flashes happen in the USA daily. We, at Care Labs understand the importance of maintaining a healthy electrical infrastructure. To help companies […]