Motor Start Analysis in USA

Care Labs provides you services like electrical safety inspections, electrical system design simulations, power systems study & analysis and arc flash study & analysis, by following guidelines of NEC, NFPA, and OSHA std. in the United States.

Care Labs offer motor acceleration analysis service to various industries including manufacturers, plants, retailers, traders, governments, NGOs, and various other buyers & sellers in the global markets.

Care Labs is an authorized ETAP service provider and using it to calculate speed, slip, output torque, load current, and terminal voltage of motor at discrete intervals from no load to full load speed

Starting issues of modern industrial motors:

Motors of modern industrial systems are becoming increasingly larger, which are even comparable to the capacity of large industrial power systems. Starting a large motor, can cause severe disturbances to the motor, connected loads, and electrically remote loads from the motor starting.

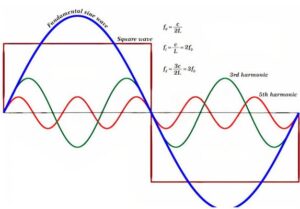

The starting torque of AC motors varies directly as the square of the applied voltage. Most AC motors draw starting inrush current about 5 to 7 times the normal full-rated load current.

In a motor-driven system, the difference between the motor inertia and the load inertia will affect the system’s performance. Inertia (WR2) plays an important role in the dynamic load character and performance of AC motors. These factors are having their effects on starting of motors.

Malfunctioning of Motor Start-up can Cause:

- Voltage dips,

- Damage to the motor,

- Power quality problems, even service disruptions,

- Nuisance tripping,

- Repetitive mechanical stress,

- Excessive running currents,

- Dimming of lights

As a consequence, it will mean production losses, unscheduled maintenance, and high additional cost to get it to start well.

Methods of starting a motor:

- Direct on-line starter

- Auto-transformers

- Soft starters

- Star-Delta Starters

- Variable Frequency Drives

The horsepower of the motor guides the selection of the size of the motor. However, to find whether it will serve a specific application, we must determine that the right combination of speed and torque is delivered.

If the produced acceleration torque by the motor is not sufficient enough to bring the motor to its operating speed within the permissible time, it may suffer from stator or rotor damage.

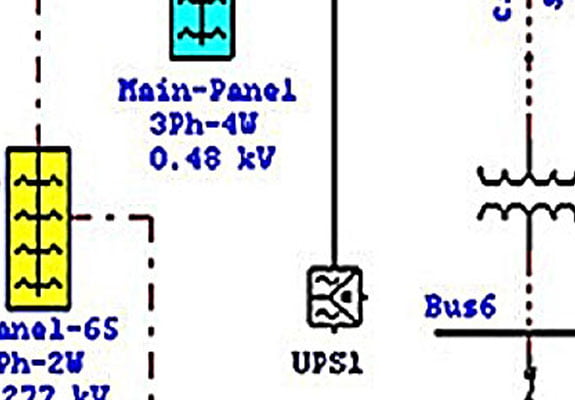

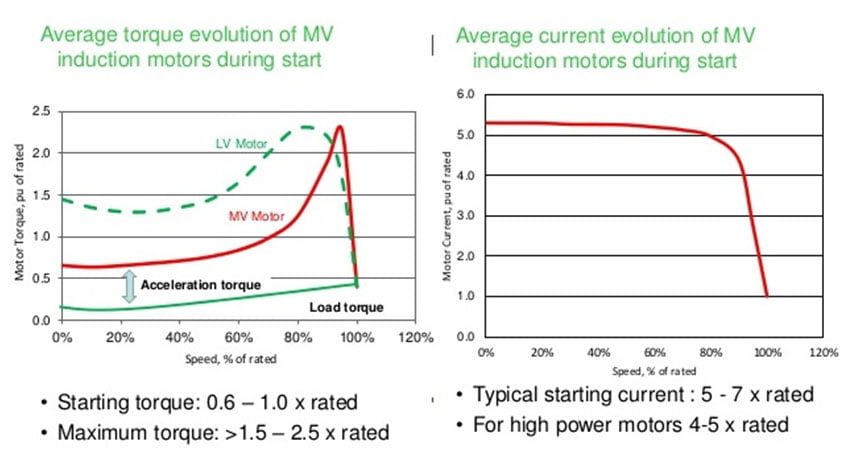

Figure.1: Induction motor torque/current vs. rated speed characteristics

There are two main things to be considered in starting AC motors: (a) the starting current drawn from the supply, and (b) the starting torque.

The starting current should be kept small to avoid heating of the motor and excessive voltage drops in the whole network. The starting torque must be up to 50 to 100 % more than the expected load torque to ensure that the motor runs up reasonably in a short time.

Motor Start Analysis:

A motor acceleration analysis is performed to find the voltages, currents, and starting time involved while starting large motors.

IEEE – 3002.7TM-2018 describes guidelines to conduct motor-starting studies and analysis of industrial and commercial power systems.

As per the standard, a motor acceleration study should be conducted, such that the motor’s life and its application performance will be satisfactory and the remaining loads of the power distribution system will not be adversely affected.

Care Labs motor start analysis is helpful for:

- The large-sized motor can be started with an existing generator rating

- The rating of the generator for a given load and largest motor size

- Knowing voltage dip during starting conditions for given motor details and deciding the key parameters while design (max allowable starting current)

- Deciding the cable size/number of runs etc.

- Reduction in motor stalling

- Reliability and life of motors improved, hence reduced costs

Care Labs performs motor starting analysis by two methods i.e., by both static and dynamic simulation techniques. Dynamic motor starting studies are more effective, that reproduce observed motor starting conditions.

Motor Start Study and Analysis Methodology:

- Initially, data collection procedures performed at the client site as per NEC requirements,

- A comprehensive model & simulation of the system is developed on power system analysis software.

- Calculations are made for the voltage drop on each feeder, bus, and the projected power flow.

- Predict the operation for new installations, diagnose problems, and offer traditional solutions that may be applied based on the data collected and project requirements.

- Results are then evaluated based on the prescribed limits by IEEE standards and the values.

- Recommendations are provided to minimize the voltage dips and acceleration issues based on the performed analysis.

Care Labs is an authorized ETAP service provider and using it to calculate speed, slip, output torque, load current, and terminal voltage of motor at discrete intervals from no load to full load speed.

Our experts utilize industry standard software to test and ensure that individual motors are functioning well. This analysis report allows us to find the impact of load changes on the power system.

The best method of starting, proper functionality of motor, and proper system design for minimizing the impact of the motor starting on the system can be provided by motor start analysis.

Care Labs offer motor start analysis service to various industries including manufacturers, plants, retailers, traders, governments, NGOs, and various other buyers & sellers in the global markets.

We offer our motor start study services in New York, Ohio, Illinois, New Mexico, New Jersey, Texas, Georgia, Florida, Washington, California, Massachusetts, Michigan, North Carolina, Pennsylvania, Virginia, and all the major states and cities in the United States of America.

Contact us today to avail of motor start study and analysis service.