OVERVIEW:

Prior to the execution of this solution, a well-known fertilizer company experienced a number of unanticipated outages caused by disruptions in the supplying utility. The power management control system at the facility had degraded and no longer provided appropriate visibility and control of the interconnection tie to the Grid.

REQUIREMENT:

Care Labs was contracted to undertake power system studies in order to assess the unplanned outages, operational inefficiencies, and make recommendations to improve system performance.

The scope also includes the replacement of Bay Control Units (BCU) and Human–Machine Interface (HMI) / Supervisory Control and Data Acquisition (SCADA) systems. Care Labs also assisted the firm in resolving the frequent failure of previously implemented EMS/SCADA, automating their operations, and reducing load shedding.

CHALLENGES:

- Lack of adequate electrical data and power system model at the firm.

- The history of events was not documented.

- Electrical data in Distributed Control System (DCS) was missing.

- Process Interruptions and frequent unplanned outages due to improper protective device settings.

- Nuisance Load shedding triggers induced by power grid frequency variations.

- Excessive termination of processes during load shedding events.

- Outdated and Faulty SCADA system

- Inadequate frequency relay setting and operation, as well as improper generator operating mode.

- High voltage drop as a result of non-sequential motor starting

- There is no infrastructure in place to carry out root cause analysis and effectively monitor energy usage

- Failures in substation control and HMI

- The operator has insufficient system expertise.

SOLUTION

Care Labs and the fertilizer firm collaborated to equip the facility with an integrated power management solution based on a novel model-based approach:

- Creating and evaluating an electrical model for the whole facility

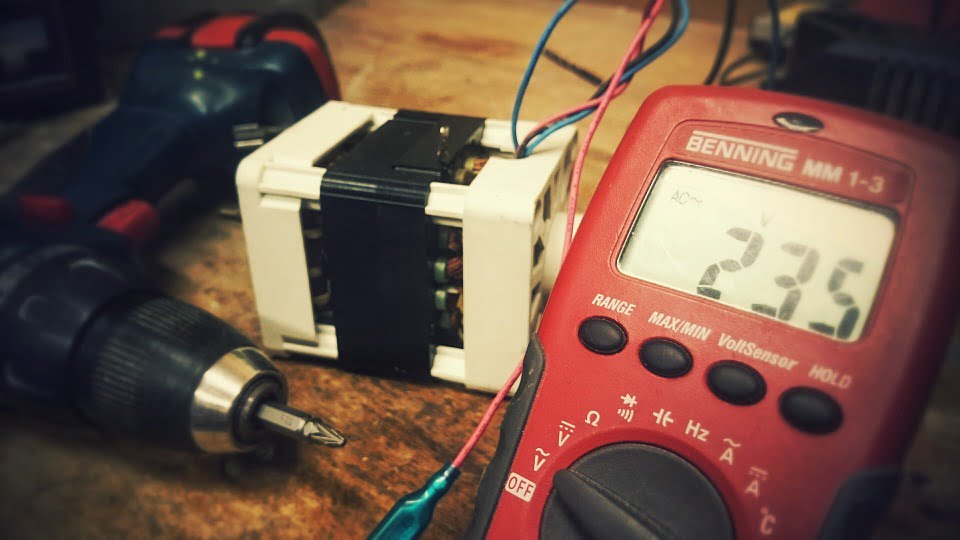

- Conducting extensive power system analysis

- Identifying operational deficiencies

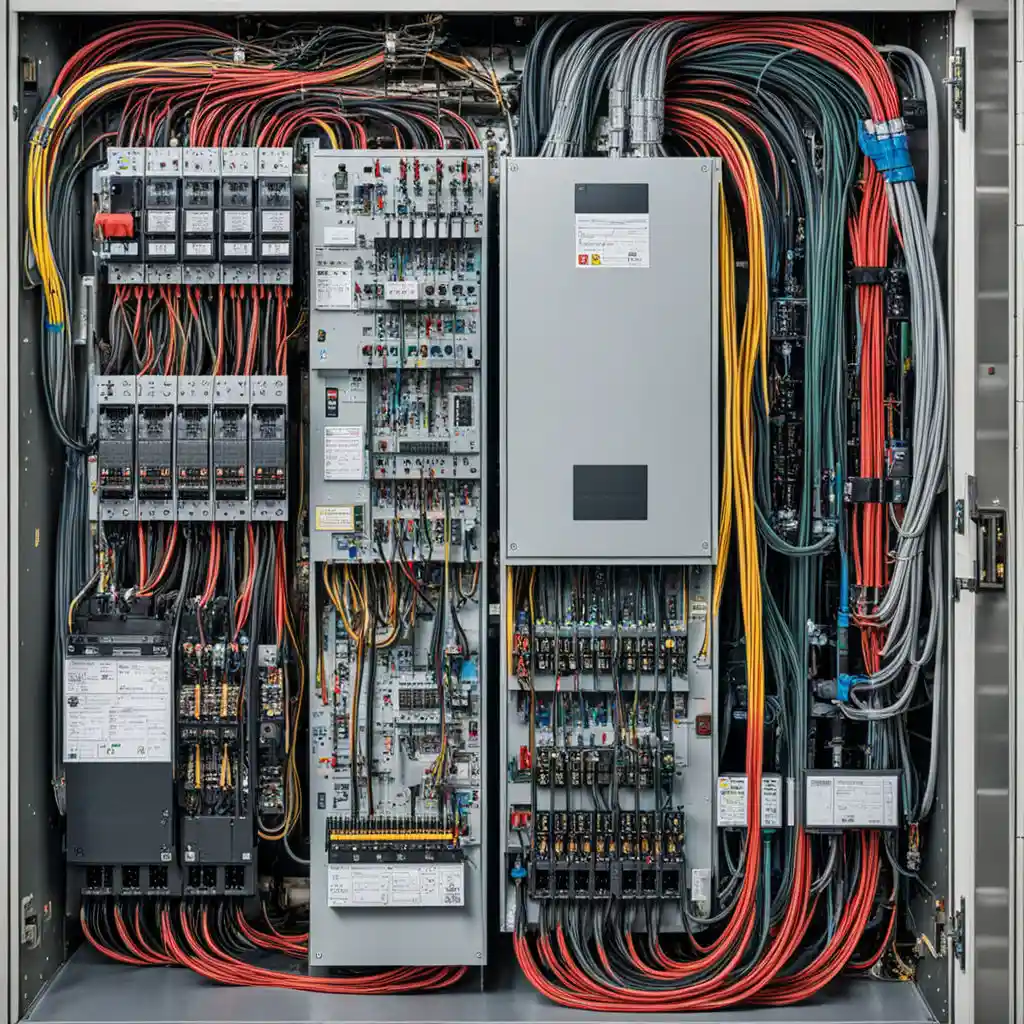

- Replacing old BCUs with new ones

- Segregating and interfacing all electrical data

- PMS tuning and implementation of the same model

- Setting up a user-friendly HMI for easy system operation

- Installation of various interlocks to prevent operational and human errors.

- Advanced monitoring and predictive simulation

- Improving grid synchronization to avoid unnecessary system shutdowns

- Estimation of state and load

- Event reenactment and root cause analysis

- Intelligent load shedding and validation

- Synchronization of the grid

- Web-based HMI dashboards installation

RESULTS

The power quality audit has been beneficial to the firm in terms of operations and validation of their plant’s power system.

- With predictive analysis, overall productivity has been increased and unnecessary system shutdowns have been drastically reduced.

- Reduced process downtime from one hour to 15 minutes

- Increased the efficiency of the operation by 75%

- ROI was 105.6% after the second year.

Over $41,000 in monthly savings on synchronization operations.