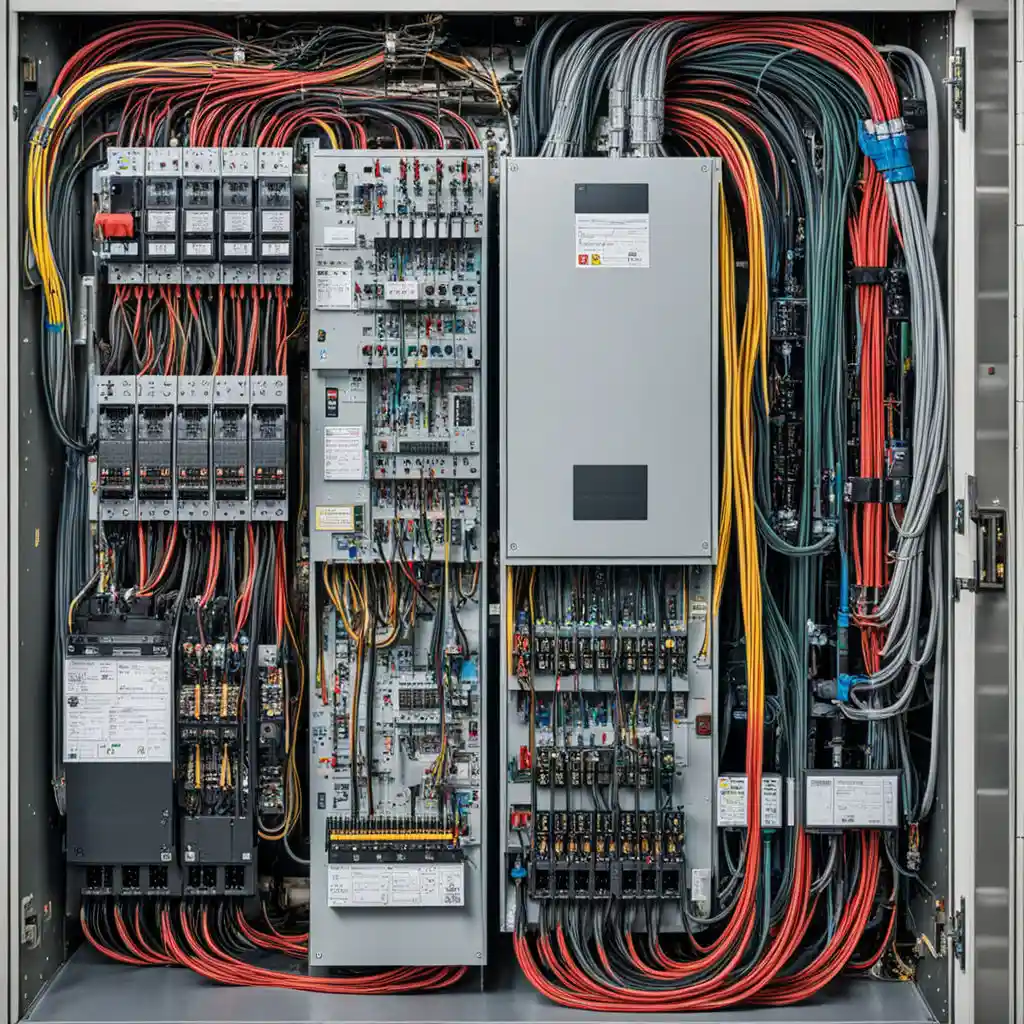

The switch gear system is connected to the electrical supply system. It is placed in the high and low voltage of the power transformer. It is used to power off equipment for maintenance and testing to correct defects

Whenever the power system fails or malfunctions (such as a short circuit), a large current will flow through the electrical equipment, which will severely damage the equipment and interrupt the user’s power supply.

The switchgear can not only power off the equipment but also complete the work and troubleshoot downstream failures.

Although switchgear is generally reliable and works well, failures are rare, this can be catastrophic. A rupture of an oil-filled GIS storage tank usually results in hot oil and gas clouds that can cause death or serious injury damage to nearby factories and buildings.

Switchgear failure may also cause serious economic losses.

Care Labs offers a comprehensive electrical switchgear risk assessment for your company to ensure that all electrical devices are safe and functional.

Switchgear is commonly used in power transmission and distribution systems and large and medium-sized commercial or industrial facilities. The IEEE (North America) and the IEC (Europe) and the rest of the world define the standards of switchgear.

Standards:

IEC 60439 (Low-voltage switchgear and control gear assemblies)

Switchgear should adhere to the Canadian Electrical Code (CEC), and National Electrical Code (NEC) standards.

How Does Switchgear Work?

The automatic switchgear protective unit mainly includes a circuit breaker and a relay.

When a fault occurs, the relay will activate and usually close a trip circuit, which automatically disconnects the fault line. After that, the useful and useful parts will handle the normal and necessary load. This means that there will be no damage to the equipment or power outages.

Types of Switchgear:

HV: High voltage switchgear

The power system monitors voltages above 36 kV, which is called high voltage.

Since the voltage is usually higher, the arc generated during switching is also higher.

Therefore, special attention should be paid to the manufacture of high-voltage switchgear. The high-voltage circuit breaker is the main part of the high-voltage switchboard. Therefore, the high-voltage circuit breaker must have special characteristics to operate reliably and safely.

LV: Low voltage switchgear

In most cases, switchgear up to 1 kV is usually referred to as low-voltage switchgear.

The term “low-voltage switchgear” includes low-voltage circuit breakers, leakage circuit breakers, HRC fuses, discharge isolators, molded case circuit breakers (MCCB), and circuit breakers (MCB).

MV: Medium Voltage Switchgear

3 to 36 kV switchgear is classified as medium voltage switchgear or medium voltage switchgear.

Most of these switches are of various types. They are usually located in outdoor metal cabinets, indoor metal cabinets, indoor or outdoor metal-free cabinets, etc.

The interrupt channels for this particular battery are vacuum, SF, and oil. The main task of a medium voltage power system is to cut off high currents in the event of a fault, no matter what type of switch is used in the medium voltage power distribution system.

Electrical Switchgear Risk Assessment:

Safety risk assessment consists of a series of steps:

- Determine the scope and scope of the geographic information system; -The design and type and classification of switchgear-environmental conditions-expected operating procedures other than normal switching operations, such as maintenance, cable testing, operation of low-voltage control equipment

- The next step involves investigating related hazards, such as electric shock, arc damage, electromagnetic fields, accumulated charges (electrical/mechanical), mechanical hazards. Hazard studies must also consider the history of operating experience, that is, the understanding of possible minor and major equipment failures.

- The subsequent risk assessment considers the severity of the damage and the possibility of its occurrence; for example-the degree and degree of damage caused by an arc fault-the switching frequency and the possibility of failure during the switching process.

- Finally, an assessment is made to determine whether the acceptable risk has been reached or whether other measures are needed to reduce the risk. This can be done using risk graphs. The acceptable risk category in this field depends on the specific industry.

- Reducing risk means prioritizing. Whenever possible, the structure itself should be intrinsically safe, and protection devices and information should be provided to users.

Protective measures:

- Elimination of the hazard

- Substitute methods that provide lower risks

- Engineering controls

- Consciousness/awareness

- Administrative control (procedures)

- Training

- The purpose of training is to ensure that all affected personnel can understand when and how dangerous situations occur and how best to reduce the risks associated with these situations.

- Personal protective equipment (PPE)

- Employees should maintain and use it as needed to ensure that the residual risk remains at the required level.

- Mitigation: Emergency procedures,

Care Labs offer switchgear risk assessment study and hazards analysis to ensure that everything at your company is up to code and in line with state regulations.

Book your inspection or get a quote today by contacting us!

Safe and Sustainable Hydropower in Canada

Hydropower in Canada- Past, present, and future! Imagine a world where 60% of the power demands are met by renewable energy sources. Wonder not, because it is a reality in Canada where hydropower is the star. Over a century ago, Canada took its first strides toward becoming a global leader in sustainable hydropower. As time […]

Cost Effective Arc Flash Study in Canada

The importance of arc flash studies in Canada’s robust manufacturing and energy sectors cannot be overstated. Why? Because it evaluates the risks associated with any electrical system. It is a core element to ensure the safety of personnel and equipment in a facility. Traditionally, it involves significant manpower, time, and resources. Enter Carelabs, a pioneer […]

The Role of Short Circuit Analysis in Enhancing Workplace Electrical Safety

Introduction Canada has one of the world’s most robust workplace electrical safety regulations. The Occupational Health and Safety (OHS) summarizes employers’ and supervisors’ rights and duties. Short circuit analysis identifies potential fault sections and their consequences in complex electrical systems. This helps develop a proper protection strategy and thus contributes to workplace electrical safety. Let […]