Electrical safety is a common practice for workers who operate and maintain electrical equipment. To reduce the risk of electric shock and prevent the dangerous consequences of accidents, a series of guidelines are followed.

Failure to comply with electrical safety requirements can lead to accidents, possible accidents, and even death.

On job sites, if workers correctly identify and control hazards, they can be very safe without any electrical hazards. However, insufficient training, experience in handling, and failure to identify potential hazards may result in electric shock or death.

The construction industry is most vulnerable to electric shock. Most of these incidents and deaths were caused by direct contact between workers and overhead power lines, as well as contact with manually moving machinery, tools, and metal objects. Conducting an Electrical Safety Evaluation is crucial to mitigate these risks and ensure workplace safety.

Things That Lead to Electrical Injuries:

- Contact with power cords

- Lack of protection against ground faults

- The ground path is missing or interrupted

- Equipment not used as prescribed

- Improper use of extension cords and flexible cables

Basic Precautions to Reduce Electrical Hazards:

- Check the wiring of the device before each use.

- Replace damaged or frayed power cords immediately.

- Every time you use electrical equipment, please follow the safe working rules.

- Know the location and procedures for handling the circuit breaker and/or circuit breaker panel. In the event of a fire or electric shock, use these devices to turn off the equipment.

- Limit the use of extension cords. Use it only for temporary operations, and only for short-term use. In all other cases, a new outlet needs to be installed.

- The multi-plug adapter must have a circuit breaker or fuse.

- Place exposed electrical conductors behind the screen.

- Minimize the possibility of water or chemicals spilling on or near electrical equipment.

There are lot ways to protect people from electrical hazard risks, including isolation, protection, proper grounding, and electrical protection devices.

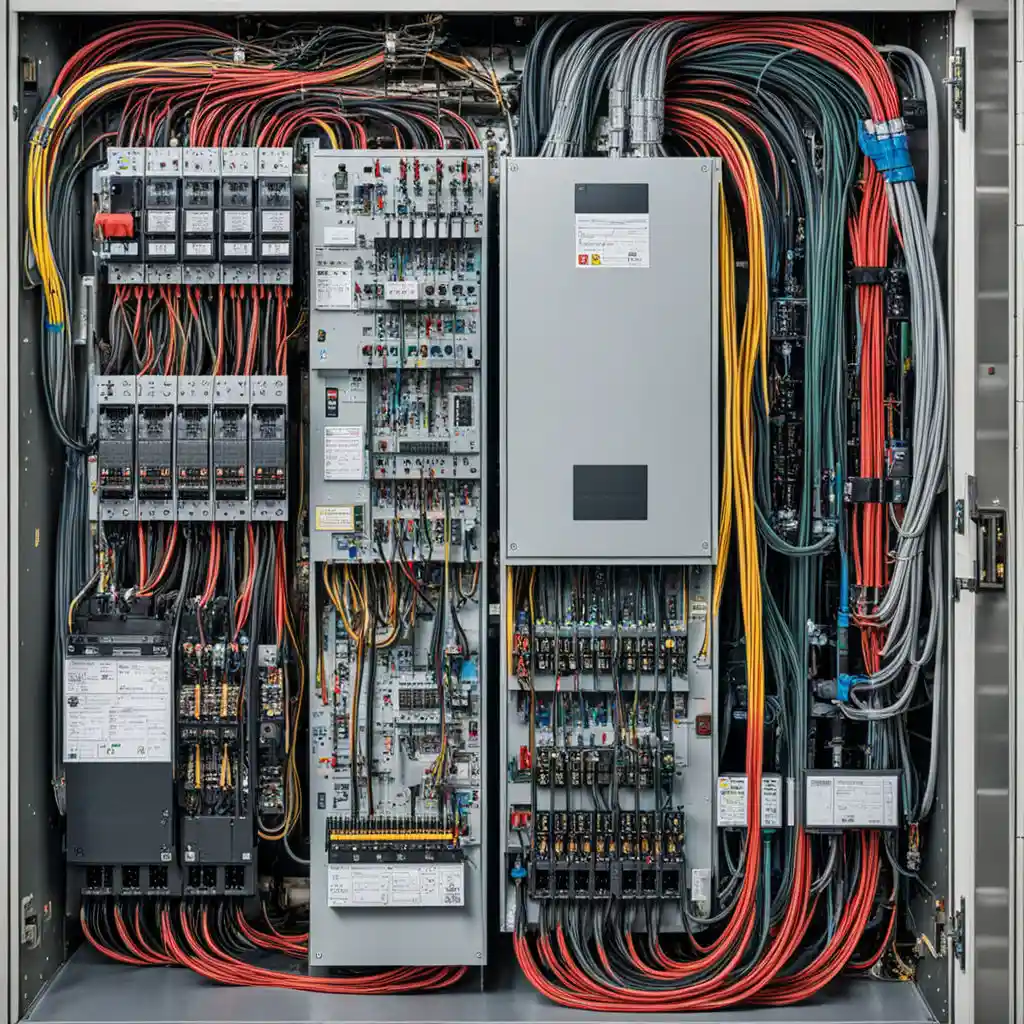

Electrical safety audit examines the complete safety of the electrical installations of any production unit or establishment. Electrical safety audits are conducted through consultation, inspection, testing, and verification.

Stats Related to Electrical Problems:

In Ontario, from 2008 to 2017, 33 workers died of electric shocks (involuntary deaths due to exposure to electricity) or electric burns at work.

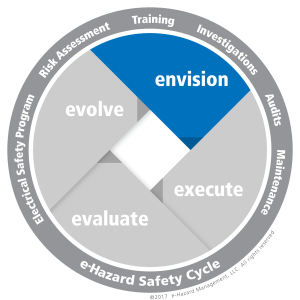

Envision: Set scope, frequency, and types of safety audits

Execute: Perform audits, based on ESP protocols

Evaluate: Review audit procedures

Evolve: Update audit policies

How Can Care Labs Help?

At Care labs, experienced electrical engineers conduct comprehensive electrical safety audits to help customers reduce risks, use standard operating procedures for electrical equipment, and help ensure compliance with applicable safety regulations.

To formulate the electrical safety plan to be implemented, the following electrical safety audit framework has been prepared. Data collection and analysis can be done in a modular manner.

- Pre-audit and coordination meeting

- Pre-audit questionnaire

- Refer to the prescribed list

- Physical inspection

- Test and measurement

- Discuss safety and power issues with employees.

- Research and review records/documents

- Prepare draft report

- Review meeting with management

- Final report submission.

Benefits of Electrical Safety Audits by Care Labs:

- Avoid damage caused by electric shock

- Compliance insurance

- Comply with laws and safety regulations.

- Higher security

- Use resources more efficiently

- Clarify electrical safety responsibilities

- Identify and eliminate security threats

- Ensure the durability of expensive electronic equipment (such as computers and other machines).

- Make sure your customers are confident that their important information (such as data and other documents) is protected from electric shock.

- Improve employee morale

- Prepare dynamic reports on safety performance

- Establish a positive safety improvement cycle

- Improve management awareness of electrical issues

- Ensure compliance with safety-related industry and government labor regulations

Standards and Guidelines:

CSA C22.2 NO. 14-18 (Industrial control equipment)

CSA C22.3 NO. 1 (Overhead Systems)

Care Labs has been approved by high, medium, and low voltage auditors who can assist in the inspection of high, medium, and low voltage installations. Conduct statutory audits to ensure the safe operation of facilities and to ensure compliance with laws, regulations, and rules.

Care Labs provides audit standards for large-scale projects to avoid unexpected delays in the audit process and provides advice on what documents and reviews are needed.

Book your electrical safety audit in Canada or get a quote today by contacting us!

Safe and Sustainable Hydropower in Canada

Hydropower in Canada- Past, present, and future! Imagine a world where 60% of the power demands are met by renewable energy sources. Wonder not, because it is a reality in Canada where hydropower is the star. Over a century ago, Canada took its first strides toward becoming a global leader in sustainable hydropower. As time […]

Cost Effective Arc Flash Study in Canada

The importance of arc flash studies in Canada’s robust manufacturing and energy sectors cannot be overstated. Why? Because it evaluates the risks associated with any electrical system. It is a core element to ensure the safety of personnel and equipment in a facility. Traditionally, it involves significant manpower, time, and resources. Enter Carelabs, a pioneer […]

The Role of Short Circuit Analysis in Enhancing Workplace Electrical Safety

Introduction Canada has one of the world’s most robust workplace electrical safety regulations. The Occupational Health and Safety (OHS) summarizes employers’ and supervisors’ rights and duties. Short circuit analysis identifies potential fault sections and their consequences in complex electrical systems. This helps develop a proper protection strategy and thus contributes to workplace electrical safety. Let […]