Explanation Arc flash hazard analysis and mitigation strategies

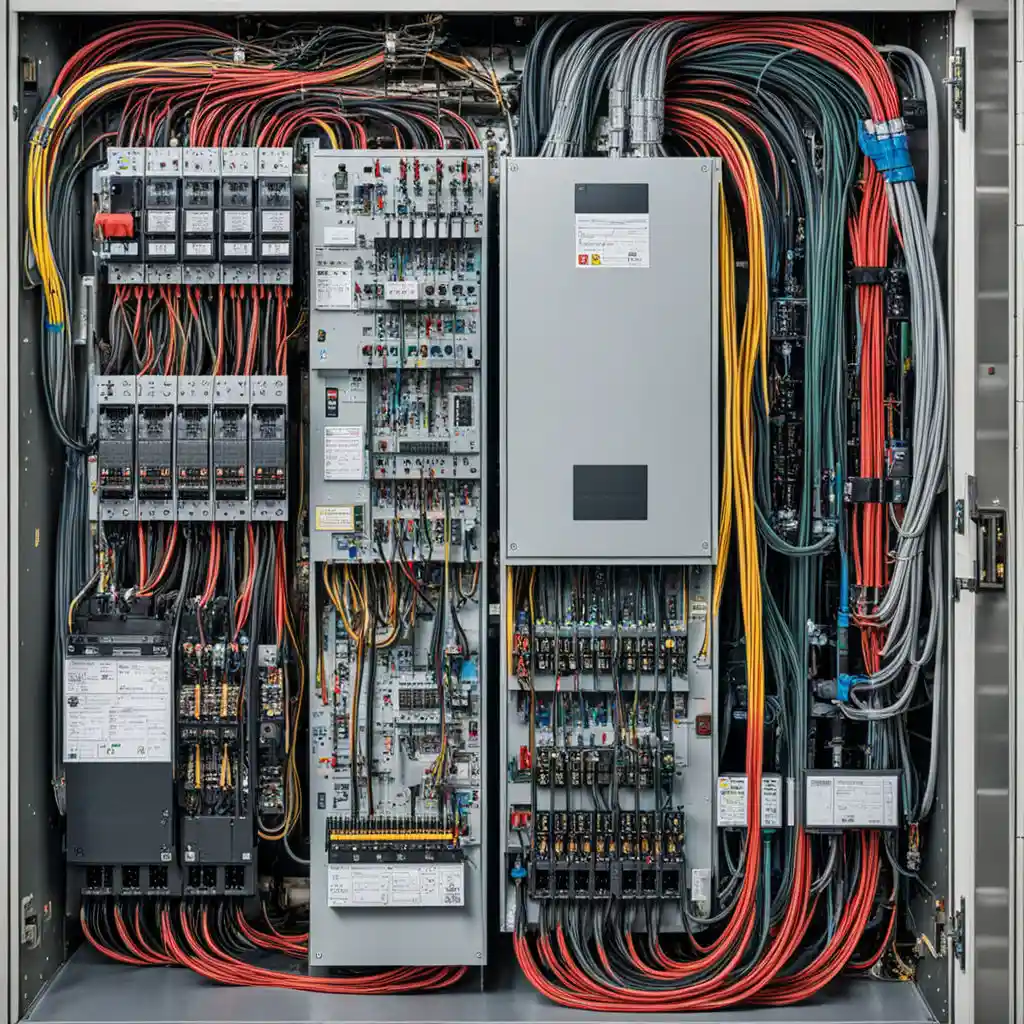

Arc flash hazard analysis involves assessing the potential risks associated with arc flash incidents in a facility. This analysis typically includes:

- Identification of Potential Hazards: This involves identifying areas in the electrical system where arc flash incidents could occur. It includes evaluating equipment, system configurations, and operational procedures.

- Arc Flash Boundary Determination: Establishing the boundary beyond which a worker could be exposed to a second-degree burn if an arc flash were to occur. This boundary helps in implementing safety protocols and protective measures.

- Arc Flash Energy Calculation: Calculating the amount of energy that could be released during an arc flash event. This helps in determining the level of personal protective equipment (PPE) required for workers.

- Equipment Labeling: Properly labeling electrical equipment with arc flash warnings, incident energy levels, and required PPE information. This ensures that workers are aware of potential hazards and can take appropriate precautions.

- Engineering Controls Assessment: Evaluating engineering solutions such as equipment design modifications, protective barriers, and arc-resistant switchgear to minimize the likelihood and severity of arc flash incidents.

- Once the hazards have been identified and analyzed, mitigation strategies can be implemented to reduce the risk of arc flash incidents. These strategies may include:

- Administrative Controls: Implementing policies, procedures, and training programs to ensure that workers understand the hazards associated with arc flash incidents and know how to work safely around electrical equipment.

- Personal Protective Equipment (PPE): Providing workers with appropriate PPE such as arc-rated clothing, face shields, gloves, and other protective gear to minimize the risk of injury in the event of an arc flash.

- Equipment Maintenance and Testing: Regularly inspecting and maintaining electrical equipment to identify and address potential issues before they lead to arc flash incidents. This includes testing for proper functioning of protective devices and conducting infrared thermography inspections.

- System Design Improvements: Upgrading electrical systems with features such as current-limiting fuses, arc-resistant enclosures, and arc flash relays to mitigate the effects of arc flash incidents and minimize their likelihood.

- Work Practices: Implementing safe work practices such as de-energizing equipment before performing maintenance or troubleshooting tasks, using proper tools and techniques, and following established safety procedures.

To know more about arc flash studies click here.

Safe and Sustainable Hydropower in Canada

Hydropower in Canada- Past, present, and future! Imagine a world where 60% of the power demands are met by renewable energy sources. Wonder not, because it is a reality in Canada where hydropower is the star. Over a century ago, Canada took its first strides toward becoming a global leader in sustainable hydropower. As time […]

Cost Effective Arc Flash Study in Canada

The importance of arc flash studies in Canada’s robust manufacturing and energy sectors cannot be overstated. Why? Because it evaluates the risks associated with any electrical system. It is a core element to ensure the safety of personnel and equipment in a facility. Traditionally, it involves significant manpower, time, and resources. Enter Carelabs, a pioneer […]

The Role of Short Circuit Analysis in Enhancing Workplace Electrical Safety

Introduction Canada has one of the world’s most robust workplace electrical safety regulations. The Occupational Health and Safety (OHS) summarizes employers’ and supervisors’ rights and duties. Short circuit analysis identifies potential fault sections and their consequences in complex electrical systems. This helps develop a proper protection strategy and thus contributes to workplace electrical safety. Let […]