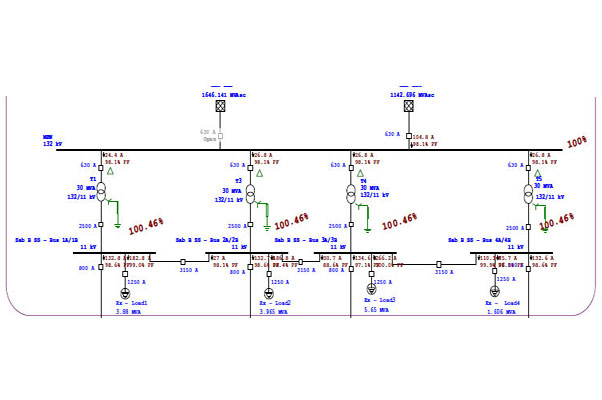

Electrical switchgear assembly is the collection of electrical network protection devices like circuit breakers, relays fuses, or switches which are topped in a metal enclosure. These devices can provide power to different sections of the system and the electrical loads of the system.

Electrical switchgear risk assessment is the quantitative and qualitative process of determining the estimated electrical hazard electrical hazard risks related to the operation of switchgear.

Switchgears are an important part of every company’s power distribution system and their damage can be catastrophic.

- The time required for the replacement and repair of switchgear is so long that it affects the productivity of the company for a long period

- A switchgear failure can prevent power flow leading to additional damage to other cables resulting in additional equipment, labor, and time to repair or replace

- Switchgear failures account for additional costs for replacing both switchgear and other equipment damaged through its failure resulting in financial loss, productivity, and more downtime

- Oil-filled switchgear failure may lead to the ejection of oil and gas resulting in injury to people getting exposed and major damage to the equipment

Causes of Electrical Switchgear Risks:

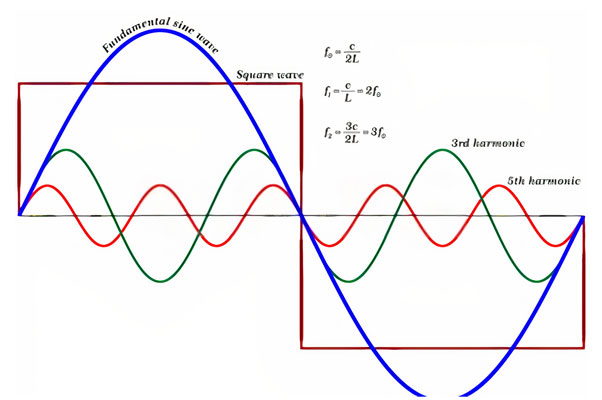

- Presence of humidity and internal arcing

- Presence of dust and surface contamination

- Deteriorated connection points or contact points

- Presence of loose connections

- Insulation breakdown

- Absence of maintenance

- Overstressing of switchgear

- Limited access and outlet

Even though switchgear failures are rare, a timely inspection must be done to ensure its safe operation.

Procedure for Electrical Switchgear Assessment:

It is important to assess the potential risks associated with the switchgear operation and manage them to make sure safe operating environment and control the risk of injury. An electrical switchgear risk evaluation identifies and takes appropriate control measures to eliminate the risks in the workplace.

- Identification of the scope of switchgear assembly which includes the design and type of switchgear, ambient working conditions, intended working conditions of the equipment

- Examining the associated hazards and risks which include shocks, arc faults, and mechanical hazards. These examinations also check into the history of services and also the faults on the equipment

- The next step involves assessing the risk factors and severity of the harms caused by these risks

- An evaluation is performed to determine the potential risk is tolerable or necessary measures are taken to keep the risks under control

- Development of an inherently safe electrical system supplemented by protective devices and information for the user

Control Measures for Electrical Switchgear Risks:

- Avoid the use of switchgear access to switchgear when it is live

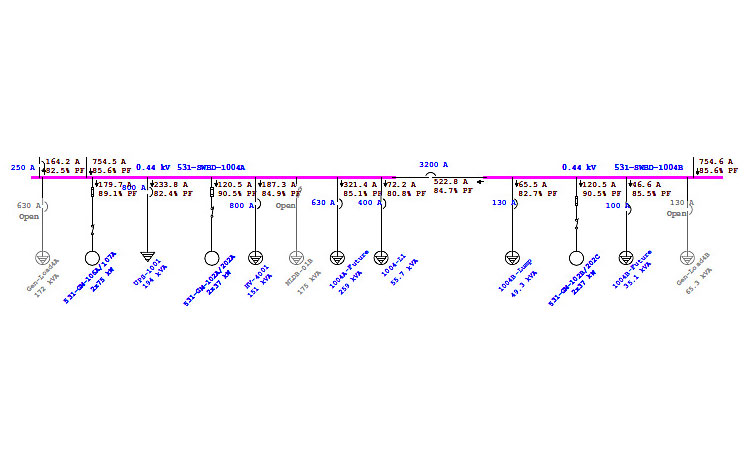

- Eliminate fault levels by reconfiguring the electrical network

- Replacing overstresses switchgear

- Avoiding the use of dependent manually operated switchgear when it is live

Case Study on Electrical Switchgear Risks:

A simple manufacturing company in Australia that runs only on utility power faced an accident involving an explosion and fire in 480V cabinets with tank rupture of the mineral oil-filled 12kV/480V transformer.

On an investigation, it is been found that the company lacked adequate maintenance.12kV switchgear battery has been discharged, 480 V circuit breaker seized and 12kV fuse for the transformer was damaged leading to the accident.

Care Labs are capable of providing electrical switchgear risk assessment for the safe operation of your company’s property and people. Trained and experienced professionals can assess the potential risks associated with your switchgear and propose appropriate control measures regarding the control of risks

Service Benefits of Care Labs:

- Prevents expensive power outages caused by undetected faults which may develop into failures

- improve substation performance, reliability, safety, and regulatory compliance

- Reduce the operational and capital costs of electrical systems

- development of a fully integrated system

- ensure a safer work environment

- Enhance the level of safety margins

- Avoid potential fines and litigation costs

Australian Standards for Switchgear Risk Analysis:

AS/NZS 61439 series is a standard for Low Voltage-LV electrical switchgear and control gear sets in workplace. It is a copied version of the IEC 61439 series for specific to Australia and New Zealand.

This standard includes 8 parts which are:

- Guide for buyers which can be used at the tender

- General rules

- Low voltage electrical switchgear and control gear sets

- Distribution boards which are intended to be operated by workers

- Assemblies for construction sites

- Assemblies for electrical power distribution in utility network

- Busbar trunking system

- Marina, camping, and charging

Care Labs have their crew members deployed in various locations, so our specialists are nearby in case of a routine or emergency. In a very short period, Care Labs has been established as an ISO 9001:2008 certified organization and have acquired a reputed client base with excellent feedbacks.

Care Labs offer electrical switchgear risk assessment services in all the major cities of Queensland, New South Wales, South Australia, Victoria, Tasmania, and Western Australia.

Figure.1: Electricity kills in the 12 years of span data.

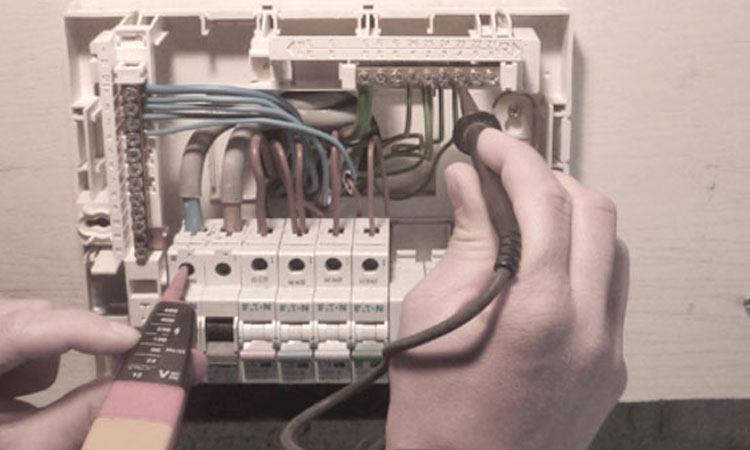

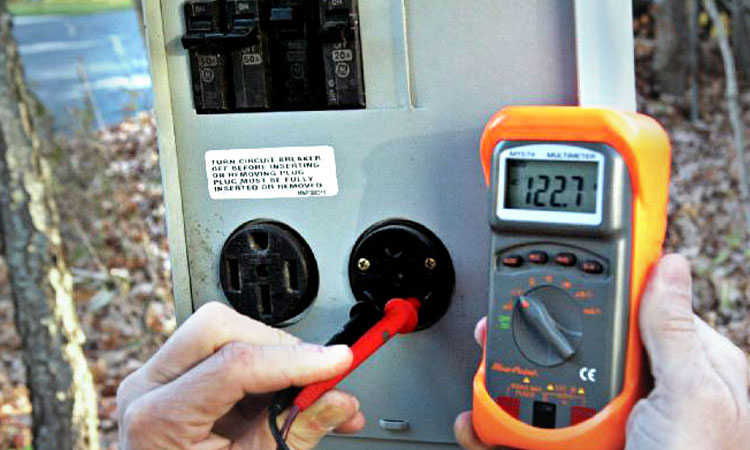

On the past 28th of March, a friend of our technician employee, contact us to perform an electrical safety inspection on their property. We perform visual inspection then, as usual, went for testing and found improper wiring, which can be devastating in future times.

Care Labs technician performs an electrical safety inspection and delivers the clients a quality work in small TAT. After that important electrical safety inspection, our technician provides him a digital inspection report, for the guarantee the safety of their employee, as well as equipment.

If he (a friend of our employee) can do that, then why not you. Having an electrical safety inspection, not only helps you in taking responsibility for employee’s safety, as well as saves your further expenses, which can be caused due to fault or damage to expensive equipment.

Care Labs Service Benefits:

Benefits which you can take advantage of, choosing Care Labs services for your safety concern.

- Focusing on our work is our primary motive.

- We deliver the quality of workplace to work.

- The technician offered by Care Labs always carried with necessary equipment and tools.

- Having experienced electricians makes our team wonder.

- After every inspection, we issue a digital electrical inspection report to the client for their guaranteed safety.

- The issue report has every detail of our action, which is good to know the clients.

- Taking feedback from you, after electrical inspection is our necessary criteria to follow our company first motive customer satisfaction.

- We provide free electrical inspection if we found any misbehave from our side.

Standards:

AS/NZS 3760 is an Australian Standard having goal is to ensure the workplace or facilities are safe by setting recommendations about testing 240 volts, three-phase, and low voltage electrical equipment.