ELECTRICAL SWITCHGEAR RISK ASSESSMENT IN AUSTRALIA

Care Labs provides several services for electrical installations such as electrical safety inspection, testing, calibration, and certification services and we offer electrical switchgear risk assessment and hazard analysis services for all types of buildings.

Our qualified and experienced professionals will examine electrical switchgear assembly risks, workers safety training programs, documentation, and PPE to ensure your electrical safety program is relevant, compliant, and comprehensive.

Care Labs are capable of efficient assessment of risks in using switchgear to manage its safe operation and to minimize the risk of danger. Care Labs help in identifying and taking sensible appropriate measures to control the risks in your workplace.

What is Electrical Switchgear?

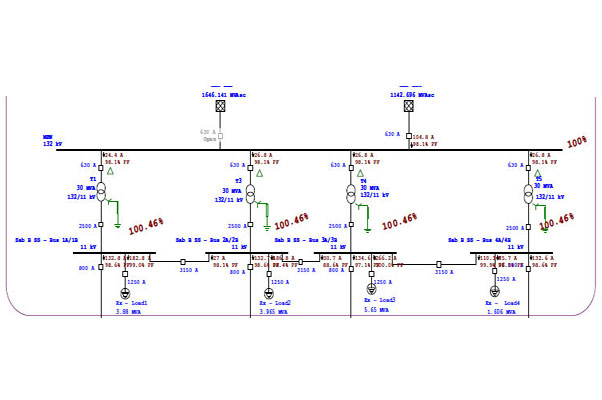

In an electrical infrastructure, switchgear is an assembly of electrical disconnecting switches, relays, circuit-breakers, or fuses that are used to control, protect, and isolate electrical equipment. It can be used to de-energize electrical equipment to carry out maintenance work and to clear faults downstream. Switchgear operation is directly related to the reliability of the electrical supply.

Switchgear interrupts electrical short circuits and overload fault currents while allowing uninterrupted service to healthy networks. Switchgear provides separation of circuits from power supplies and enhances system availability by allowing more than one source to feed a load.

There are three types of switchgear based on the level of voltage:

- Low voltage switchgear

- Medium voltage switchgear

- High voltage switchgear

Risks and Problems Associated with Switchgear:

- Absence of maintenance

- Overstressing of switchgear

- Movement of switchgear dependent on the movement of the operating handle

- Absence of anti-reflex handles

- Insufficient means of protection against fire

- limited access and outlet

Reasons for Electrical Switchgear Failure:

- Presence of dampness

- Unauthorized access/interference

- Damaged condition of firefighting equipment

- Failure in general housekeeping

- Conditions like high temperature, hot substances, ozone, leakage of oil/compound

- Corrosion and leaks in switchgear

- Damaged condition of labels, padlocks, and interlocks

- Damaged condition of batteries, chargers, and control panels

Over 325 electrical fatalities were reported in Australia during the year 2018-2019.

Thus, there is a high probability for the failure of electrical switchgear leading to the risks and problems mentioned above which results in the damage of both equipment and lives of people. So, a periodic electrical switchgear assessment is essential in any electrical system which includes

- Avoid operating overstressed switchgear

- Avoid access to switchgear when it is live

- Reduction in fault levels by reconfiguring the network

- Replacing overstressed switchgear

Work Process of Care Labs for Switch Gear Assessment:

- Identifying the limits and scope of use of switchgear assembly which includes design and type of switchgear and its rated values, ambient working conditions, work procedures, maintenance cable testing, etc.

- Examination of the associated hazards like an electric shock, arc faults, and mechanical hazards. It looks into the history of service experience including minor and major failures on the equipment.

- Estimation of harms and their probability of occurrence like switching rate and probability of failure on switching operation.

- Evaluation of switchgear is carried out to determine the tolerable risk, and measures for risk reduction are proposed.

- Implementation of risk reduction techniques based on priorities

Service Benefits of Care Labs:

Australia has introduced a new AS/NZS 61439 standard in 2016, completely in effect from 2021 for low voltage switchgear and control gear assemblies by replacing the old AS/NZS 3439 series.

This is a copy of the IEC 61439 series specifically for Australia and New Zealand. Key points of this standard are

- AS/NZS 61439 has 8 parts

1.Guide for specifiers to be used at the tender

2.General guidelines

3.Low voltage switchgear and control gear assembly

4.Distribution boards intended to be operated by unprofessional persons

5.Assemblies for construction sites

6.Assemblies for electrical power distribution in a network

7.Busbar trunking systems

8.Marina, camping, market, and charging

- Verification by comparison with a reference design demonstrating the new characters are better

- IEC 61439 can be used to validate the manufacturers verification assessment of the switchboard design to AS/NZS 61439

Care Labs has its crew members deployed in various locations, so our specialists are nearby in case of a routine or emergency. In a very short period, Care Labs has been established as an ISO 9001:2008 certified organization and has acquired a reputed client base with excellent feedbacks.

We offer electrical switchgear risk assessment services in all the major cities of New South Wales, Queensland, South Australia, Tasmania, Victoria and Western Australia.

Book your electrical switchgear risk assessment in Australia or get a quote today by contacting us!