Electrical arcs happen when gas is exposed to a voltage more than its insulation properties. The arc is initiated when the voltage is adequate to ionize the air across the gap between conductors.

Once ionized the gas becomes a good conductor allowing the current to flow resulting in the arched-shaped current named arc flash. An arc fault is an unintended discharge of electricity resulting in

- High temperatures from arc flash lead to blinding light and deafening noise

- Arc blast is a high-pressure wave that can give out molten metals and shrapnel

- Toxic smoke

Arc flash hazards can be disastrous to industries and electrical facilities. Some of the commercial losses from arc flash hazards include

- Extra costs on medical treatment, rehabilitation, and compensation of workers, cost of accident investigation, and downtime loss of production.

- Loss of legal costs and judgments from litigation, fines, insurance premiums repair costs, and costs for replacement workers.

- Hostile impact on the company’s name and reputation.

- Loss of business opportunities due to the history of accident rate leading to even the cancellation of electrical license.

Causes of Electrical Arc Flash:

- Broken conductor insulation

- Exposed live parts

- Human carelessness

- Improper maintenance of switches and circuit breakers

- Presence of water near the equipment

- Obstructed disconnect panels

- Cables of high voltage

- Static electricity

- Damaged tools and equipment

Steps of Arc Flash Analysis:

Arc flash hazards generally occur wherever high voltage or low voltage high current switching occurs.

Step 1: Assess the Risk of Arc Flash:

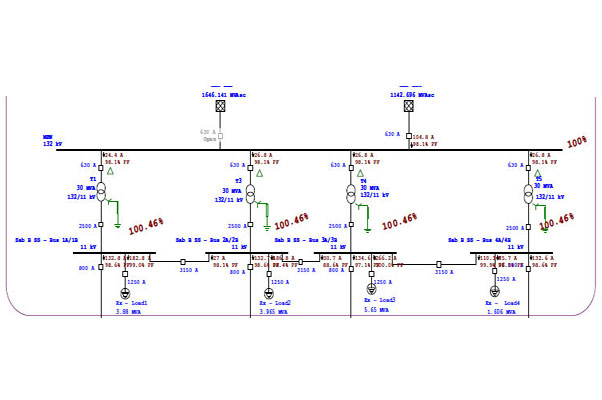

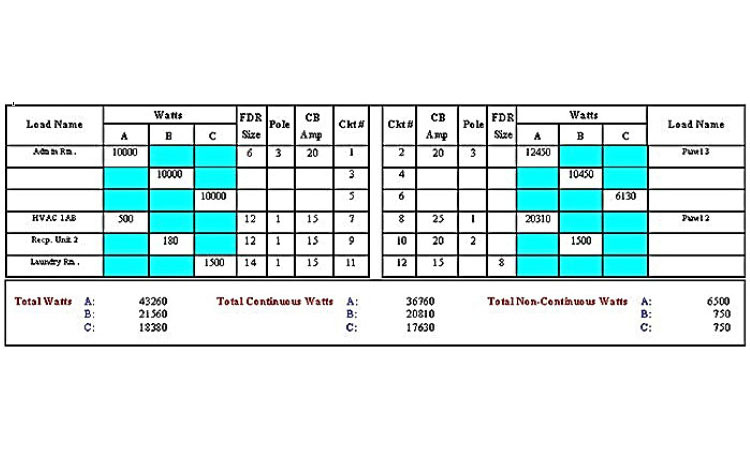

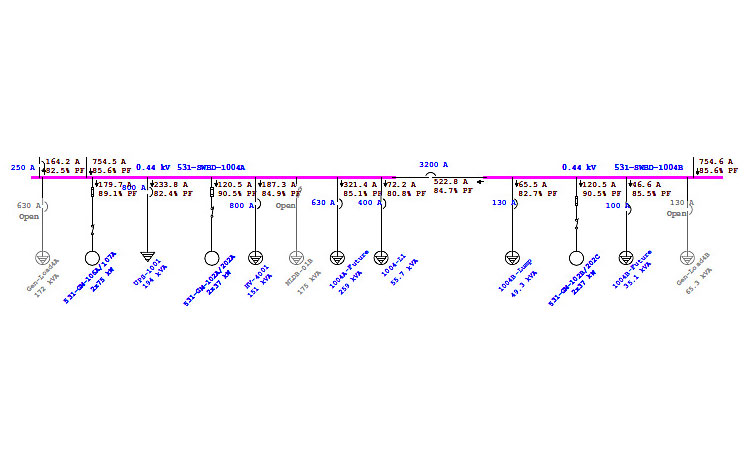

- Undergo an arc flash/fault study or analysis which include data collection, power system modeling using software, short circuit study, overcurrent protective device coordination study, arc flash study, and arc flash evaluation

- Determination of probability of a worker being exposed to an arc flash event

Step 2: Treat the Risk:

- Removal of exposure of workers to arc flash hazards by interacting only with de-energized equipment

- Replace manual operating systems with automated systems

- Separate workers from hazards by installing physical separation from energized equipment

Step3: Engineering Control:

- Reduce incident energy using reduced fault current

- Arc flash detection and suppression systems

- Remote controls and switching

- Upgradation/modification of switchboards

- Installation of fixed circuit breakers

- Bus bar insulation

- Replacement of damaged fuses

Step4: Administrative Controls:

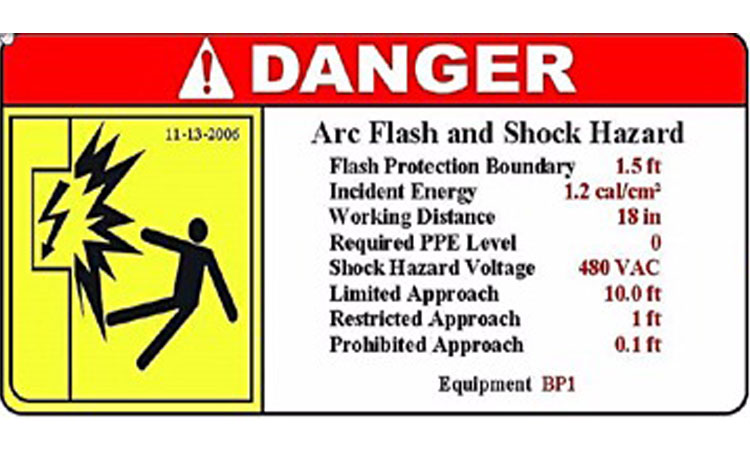

- Labeling of switch rooms, plants, and relevant locations for identifying the incident energy levels

- Labeling of arc boundaries

- Registering arc flash details and diagrams

- Ensuring safe policy and procedures that reduce exposure

- Implementing incident energy and PPE levels

Step 5: Personal Protective Equipment:

- Even though they are the least effective, PPE may reduce the severity of the injury but do not prevent injury. Appropriate PPE is selected based on the incident energy levels

Arc Flash Case Studies in Australia Stats:

- An arc flash explosion happened in Western Australia in 2015 in a shopping center while electrical workers were conducting maintenance on an 11kV fuse switch killing two people and severely injuring two others

- An electrical worker received severe electrical burns to his upper torso following an arc flash while working at Perth on 4 November 2019

- Two electricians suffered from burns from arc flash while working in a switch room with a low voltage main switchboard in January 2021 in Queensland

- An electrician was injured working near energized electrical parts which caused a short circuit and arc flash in February 2021 in Queensland

Care Labs are capable of providing a solution to all your arc flash-related hazards. Well-trained and experienced professionals are capable of identifying potential arc flash hazard risks and can propose appropriate mitigation and control methods to ensure the safety of your people and property.

Care Labs Service Benefits:

- Safer power systems according to government standard rules and guidelines

- Save time and money with fully integrated power systems

- Ensure a safer working environment

- Propose quick alternatives in case of emergency

- Increase safety margins

- Save time by automatic generation of arc flash label and work permits

- Avoid potential fines and litigation costs

Australian Guidelines for Arc Flash Analysis:

Australian Energy Council published the electrical arc flash hazards management guidelines in march 2019 for the awareness of arc flash hazards and to minimize the risk of injury

This guideline focuses on the collective electric arc flash hazard knowledge and experiences. It describes the hierarchy of control for arc flash management.

It identifies many arc flash control measures like proving the electrical equipment is de-energized, IR thermography, racking, etc.

Care Labs have their crew members deployed in various locations, so our specialists are nearby in case of a routine or emergency. In a very short period, Care Labs have been established as an ISO 9001:2008 certified organization and have acquired a reputed client base with excellent feedbacks.

Care Labs offer arc flash study and analysis services in all the major cities of Queensland, New South Wales, South Australia, Victoria, Tasmania, and Western Australia.