Hungarian Guidelines

for Testing and

Verifying Electrical

Motor Efficiency

In the global economy, industrial electric motors power a wide range of applications. According to estimates from the International Energy Agency (IEA), up to 70% of all energy used in industrial settings, 35% of all energy used in the commercial and service sectors, and 45% of all power generated globally are all attributed to the automotive industry. Electric motors are crucial in many industrial applications, as evidenced by the hundreds of dollars per hour that motor-related downtime costs. They bear most of the blame for power plant greenhouse gas emissions and environmental harm. They are also largely to blame for the developing world’s sharply rising energy consumption. With typical payback times of under three years, there is a global economic potential to increase industrial motor energy efficiency by 20 to 30%. About 15%, or 4.3 billion tons, of the world’s annual emissions of 26 billion tons of carbon dioxide are attributable to electric motors. One of the most affordable and risk-free ways to minimize rising energy consumption and greenhouse gas emissions is to increase energy efficiency.

Use a powerful motor for the following purposes:

- Reduced operating expenses

- The motor’s dependability and lifetime were increased

- Its greenhouse gas emissions were reduced,

- For a quieter and more steady operation.

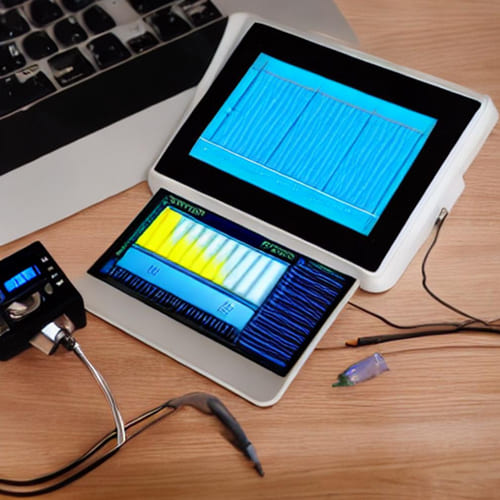

Start of the Motor Analysis:

A percentage of the energy lost by electric motors is due to windage and friction losses, as well as losses in the stator, rotor, and magnetic core. The decline in motor efficiency is caused by these losses. It is obvious that efficiency evaluation and minimal energy performance standards are necessary and appropriate given the energy consumption and industrial use of electric motors. Depending on the test method used, the predictions for motor efficiency and motor loss may not be accurate. Various testing techniques are used in various sectors. Although it is a straightforward concept, it may be difficult to assess and certify a motor’s energy efficiency using numerous criteria.

Internationally recognized methods for evaluating efficacy:

It is common to talk about the following testing methods in industrial applications:

A common test method for polyphase motors and generators is IEEE 112-2004. IEC 60034-2-1 tests, 2014, International Electrotechnical Commission. techniques for figuring out how efficient and wasteful spinning electrical equipment is. The Japanese Electrotechnical Committee created JEC 37 as a standard for induction devices. ANSI/IEEE 112-2004

Ten techniques for measuring energy efficiency are included in this strategy. To use the most crucial:

- Fundamental input and output testing.

- Verify that there is no loss in the input or the output.

- Test for connected machines with separation loss conducted back-to-back.

- Using smoothed residual losses to calculate load loss

- The Eh-star approach

The three main categories covered by the IEC standard test are:

- Figuring out a machine’s input-output power.

- Measurement of two machines’ input-output power simultaneously.

- One machine’s losses were totaled.

The increased load losses are completely disregarded in the test methods for the Japanese JEC standard 37. Reducing operating expenses for businesses is one of the most important economic and environmental benefits of improving the energy efficiency of machinery and appliances. We provide motor start analysis services in all major Hungary cities, including Budapest, Debrecen, Szeged, and Miskolc.

RELATED NEWS

How Are the Dependability and Performance of Commercial Motors Assessed? The easiest, most affordable, and fastest way to get consistent …

Hungarian Guidelines for Testing and Verifying Electrical Motor Efficiency In the global economy, industrial electric motors power a wide range …

The Importance of Load Flow and Short Circuit Analysis to a Hungarian Business Everyone is aware of how important energy …

Why Analysis of the Power System Considers Relay Coordination, Short Circuits, And Load Flow? To provide your facility with a …

Principles of Operation for the Power Quality in Hungary The performance and basic operation of the equipment connected to the …

How to Analyze the Power Quality in Hungary? The ability of equipment to use the energy supplied to it is …

Why Are Harmonic Why Are Harmonic Research and Analysis Research and Analysis So Crucial to Hungarian Businesses? Hungarian Businesses? Since …

Analysis of the Hungarian Power System’s Harmony: System’s Harmony: Power is a necessary component of life in the modern day. …

Hungarian Arc Flash Analysis: A Complete Guide A Complete Guide When a gas is exposed to a voltage that exceeds …

Analysis of Arc Flash Analysis of Arc Flash Hazards and Mitigation Techniques: Mitigation Techniques: Electrical arcs can develop when a …