Hungarian Arc

Flash Analysis:

A Complete Guide

A Complete

Guide

When a gas is exposed to a voltage that exceeds its insulating capacity, electrical arcs form. The arc starts when the voltage is high enough to ionize the area between the conductors. A gas becomes a great conductor when it is ionized, allowing current to flow, and producing the arc-shaped current known as an arc flash. Unintentional electrical discharge that starts a fire is known as an arc fault.

- High heat produced by arc flashes causes bright brightness and a loud boom.

- A high-pressure wave called an arc blast has the power to spew metal molten and fragments.

- Noxious vapors

Arc flash dangers have the ability to seriously hurt business operations and electrical infrastructure. Arc flash dangers result in the following business losses:

- In addition, there will be additional expenditures for counselling, workers’ compensation, medical care, accident investigation, and missed productivity.

- Legal fees and judgements connected to disputes, fines, insurance premiums, and costs associated with replacing and repairing people.

- Detrimental effect on the company’s reputation and brand.

- A reduction in economic opportunities brought on by a history of mishaps that might lead to the suspension of an electrician’s license.

When Does an Electrical Arc Flash Occur?

- Visible organs on a circuit with inadequate insulation

- Human beings are careless

- Circuit breakers and switches that are not maintained well

- There is cause for concern when there is water close to the apparatus.

- Disconnect any panels that are blocked.

- Installation of high-voltage wire

- Ionization unleashes faulty tools and equipment

Arc Flash Analysis Technique:

An arc flash is a potential whenever high-voltage or low-voltage, high-current switching takes place.

First Phase: Determine the arc flash danger:

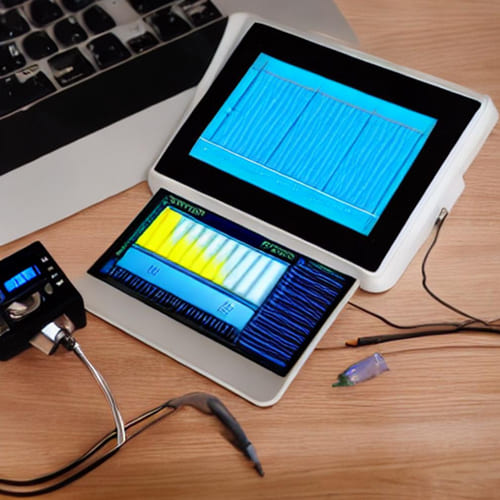

- Complete an arc flash/fault analysis or study, which should include data collection, software-based power system modelling, short circuit analysis, overcurrent protective device coordination study, arc flash analysis, and arc flash evaluation.

- Assessment of a worker’s potential exposure to arc flash

Second Phase: Risk Management:

- Reducing worker exposure to arc discharge hazards by limiting interaction to deenergized apparatus

- Instead of manual mechanisms, automated ones should be used.

- Install physical barriers between laborers and energized machinery to protect them from potential dangers.

Third Phase: Engineering control:

- Reduce incident energy by decreasing short circuit current.

- Detection and suppression systems for arc flares.

- Changing and distant controls

- Upgrades or modifications to the switchboard

- Installing permanent circuit breakers

- Insulating material for transit rail

- Alteration of damaged fuses

Fourth Phase: Administrative controls:

- Identifying incident energy levels by labeling switch rooms, plants, and other relevant locations.

- Arc boundary designation

- Documenting arc discharge data and diagrams.

- To limit exposure, ensure safe policies and procedures.

- Implementing incident energy and PPE levels

Fifth Phase: Personal safety gear (PPE (Personal Protective Equipment):

- Personal protective equipment can lessen an accident’s severity but cannot stop it from happening. It can lessen the severity of an injury even though it is the least effective. The type of personal protective equipment (PPE) used depends on how serious the incident is.

Every arc flash hazard is addressed by CareLabs with a solution. Professionals with the necessary knowledge and skills should evaluate potential arc flash danger hazards and apply suitable mitigation and control measures to safeguard your personnel and property.

Advantages of CareLabs Service:

- More secure power systems in accordance with government guidelines and standards.

- Power systems that are fully integrated save time and money.

- Create a more secure work environment

- When the situation demands it, provide simple solutions.

- Increase the safety margins

- You may gain time-saving benefits by automatically creating arc flash labels and work permits.

- Avoid potential fines and legal troubles.

To guarantee that our professionals are accessible in the event of a routine or urgent emergency, CareLabs has people stationed in many locations. CareLabs has quickly become an ISO 9001:2008-accredited organization and gathered a clientele with a solid reputation and high ratings. Arc flash investigation and analysis services are offered by CareLabs in several significant cities, including Budapest, Debrecen, Szeged, and Miskolc.

RELATED NEWS

How Are the Dependability and Performance of Commercial Motors Assessed? The easiest, most affordable, and fastest way to get consistent …

Hungarian Guidelines for Testing and Verifying Electrical Motor Efficiency In the global economy, industrial electric motors power a wide range …

The Importance of Load Flow and Short Circuit Analysis to a Hungarian Business Everyone is aware of how important energy …

Why Analysis of the Power System Considers Relay Coordination, Short Circuits, And Load Flow? To provide your facility with a …

Principles of Operation for the Power Quality in Hungary The performance and basic operation of the equipment connected to the …

How to Analyze the Power Quality in Hungary? The ability of equipment to use the energy supplied to it is …

Why Are Harmonic Why Are Harmonic Research and Analysis Research and Analysis So Crucial to Hungarian Businesses? Hungarian Businesses? Since …

Analysis of the Hungarian Power System’s Harmony: System’s Harmony: Power is a necessary component of life in the modern day. …

Hungarian Arc Flash Analysis: A Complete Guide A Complete Guide When a gas is exposed to a voltage that exceeds …

Analysis of Arc Flash Analysis of Arc Flash Hazards and Mitigation Techniques: Mitigation Techniques: Electrical arcs can develop when a …