Analysis of Arc Flash

Analysis of Arc

Flash

Hazards and

Mitigation Techniques:

Mitigation

Techniques:

Electrical arcs can develop when a gas is subjected to a voltage that is higher than the gas’s insulating capacity. An arc will occur when the voltage is high enough to ionize the area between the conductors. Ionized air has increased conductivity, which enables electricity to move through it. Ionization of the air creates a current that emits heat and bright light. The way in which this heat forces ionized air to ascend and create an arch-shaped circulation gives rise to this phenomenon. The temperature of an arc flash is 20,000 degrees Celsius.

Arc flash hazards put people and property at peril. Arc in flash has several business repercussions, including:

- The cost of an accident investigation, lost production, and worker compensation are all examples of direct expenses.

- Legal and judgement fees, litigation costs, fines, insurance premiums, repair costs, and replacement worker fees are examples of indirect expenditures.

- The possibility of receiving criminal charges, your reputation, and your capacity to compete on the job market are examples of consequences.

- Customers reject electrical contractors that have a high incident rate, which can lead to missed business opportunities and even license revocation.

- The usage of electrical circuits in accidents Flash usually leaves a lasting impact, leading to lost opportunities and squandered resources.

Causes of Arc Flash Hazard:

- Utilizing the test instrument on an improper surface.

- Inappropriate equipment, installation, and methodologies of labor.

- Using electrical components that are flawed.

- Insulation damage or equipment openings.

- Disconnect panel interference.

- Electrical equipment grime or corrosion.

- Unsuitable circuit breaker and switch maintenance.

- Exposed vital organs or a frayed connection.

- High-voltage wires or a constant power source.

- Electrical equipment moisture.

Techniques for Reducing Arc Flash Risk:

Electrical Equipment Shutoff:

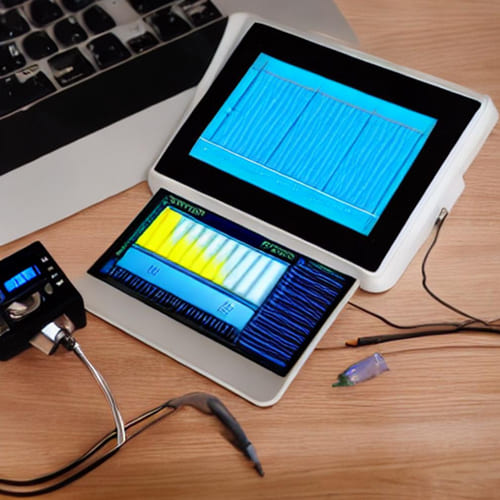

It reduces risks as much as is practical. When testing or re-energizing de-energized equipment, proceed with utmost caution. With the use of remote tracking technology, circuit breakers are maintained away from arc flash boundaries that might endanger their users.

Make Use of Low-Risk Technology:

An arc flash analysis and power system study are carried out to ascertain the risks connected with short circuits and the coordination of preventive devices. Protect people and property by using low-threat choices, such as remote rack equipment.

Reconceptualize Electrical and Control Systems:

Make sure you have access to the degree of PPE (Personal Protection Equipment) necessary by the arc flash hazard category before redesigning your electrical and control systems. To reduce risks, engineering practices and techniques are being modified. Energy distribution systems and breakers are made to reduce incident energy.

Reduce the Level of Available Fault Current:

The industry will benefit from circuit breakers without current restrictions by lowering the level of fault current that is available. With an open tie, these tools can be used for maintenance. By reducing the available fault current during maintenance, opening the link between dual power supplies reduces the risk of an arc flash.

Change The Energy of the Blast:

Current-limiting reactors can successfully stop the flow of electrical current during arc faults by impeding it. Encourage the use of arc-resistant materials to alter the weapon’s energy. Energy and heat from an arc flash are transferred through ducts to an unoccupied area using arc-resistant switchgear with sealed joints, pressure relief vents on top, and stronger hinges. Arc flash is thoroughly investigated by CareLabs. Arc flash risks are assessed by experts to help you enhance your safety program.

CareLabs is able to locate and put into practice cutting-edge strategies for averting arc flash risks. CareLabs is prepared to conduct and put into practice innovative arc flash risk reduction research. ETAP (Electrical Transient Analysis Program) software is used in CareLabs for research and analysis. Crew members are placed in various locations to ensure our knowledge is available in routine and emergency circumstances. We quickly attained ISO 9001:2008 accreditation and loyal clients. Cities in Hungary include Budapest, Debrecen, Szeged, and Miskolc.

RELATED NEWS

How Are the Dependability and Performance of Commercial Motors Assessed? The easiest, most affordable, and fastest way to get consistent …

Hungarian Guidelines for Testing and Verifying Electrical Motor Efficiency In the global economy, industrial electric motors power a wide range …

The Importance of Load Flow and Short Circuit Analysis to a Hungarian Business Everyone is aware of how important energy …

Why Analysis of the Power System Considers Relay Coordination, Short Circuits, And Load Flow? To provide your facility with a …

Principles of Operation for the Power Quality in Hungary The performance and basic operation of the equipment connected to the …

How to Analyze the Power Quality in Hungary? The ability of equipment to use the energy supplied to it is …

Why Are Harmonic Why Are Harmonic Research and Analysis Research and Analysis So Crucial to Hungarian Businesses? Hungarian Businesses? Since …

Analysis of the Hungarian Power System’s Harmony: System’s Harmony: Power is a necessary component of life in the modern day. …

Hungarian Arc Flash Analysis: A Complete Guide A Complete Guide When a gas is exposed to a voltage that exceeds …

Analysis of Arc Flash Analysis of Arc Flash Hazards and Mitigation Techniques: Mitigation Techniques: Electrical arcs can develop when a …