How Are the

Dependability

and Performance of

Commercial Motors

Assessed?

The easiest, most affordable, and fastest way to get consistent electricity is to increase energy efficiency. In the industrial sector, motors use around 46% of the total power and 69% of the total energy. One of the most significant challenges that many organizations encounter is energy use. The first thing that has to be fixed are poor design and excessive energy use. The main causes of rising energy prices and the inability to meet the growing demand for electricity are poor design and improper use. Most motors operate between 50% and 100% of rated load; the highest efficiency is 75% of rated load, and it deteriorates over time. At 50% load, an electric motor’s efficiency starts to degrade automatically.

Four Variables That Affect Motor Performance Include:

- Poor power quality has a direct effect on motor performance since transients, imbalance, sags, swells, and harmonics can seriously hurt a machine or even cause it to malfunction.

- The effect of torque on effectiveness and overall performance is seen when a motor generates rotational force to drive a mechanical load at the rated speed of the spinning shaft. Given that it operates at the required frequency and torque speed, the electric motor is trustworthy. An electric motor’s condition may be accurately determined by measuring torque.

- The electric motor’s anticipated performance and its operational circumstances: The connection, bearings, and insulation are only a few of the internal parts of the motor that are mechanically strained by overloading. This lowers the motor’s efficiency and increases the likelihood of malfunction or early failure.

- The first step in predictive and preventative maintenance is gathering baseline data since motor efficiency is directly related to it.

An annual downtime of 1-6 days per site is the consequence of 75% of industrial motor breakdowns. 90% of motor failures occurred within a month after the early warning, and 36% occurred within a day. To avoid motor failure and operational issues Regular assessments, analyses, inspections, and audits may help to lessen all electrical motor problems and improve the reliability and performance of the motors.

Information About Enhancing Motor Function:

Increase an induction motor’s efficiency by 68% over a 53-year period (1960 to 2013). Minimize losses in electrical induction motors over the course of a year to boost efficiency. The energy efficiency of induction motors has risen throughout time (data of 45 kW, 4p design motor). Electric motor reliability and performance are evaluated by Care Labs for a variety of commercial structures and industries. To help you minimize losses and improve motor performance, we discover and investigate problems. As seasoned professionals with skill, our goal is to provide clients with outstanding services.

Benefits from Employing Care Labs' Services Include:

- Always takes full responsibility for our work

- Outstanding customer service.

- Quick responses to your chats.

- The presence of a capable and competent electrician benefits our team.

- Knowledge of Hungary norms.

- Decide on a time that works for the appointment.

- Offer a digital report with all the necessary details to ensure your total satisfaction.

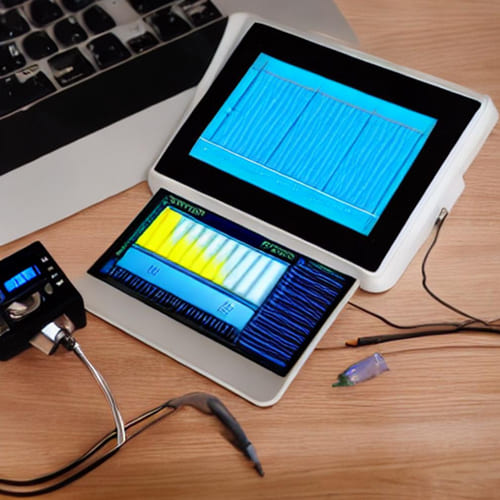

Methods for Conducting Electrical Motor Efficiency Audits:

- We gather all site-related documentation prior to the audit starting for research purposes.

- To advance your position, create a one-line diagram and an inspection checklist.

- Utilize the inspection checklist for electrical motors to continue the audit.

- Technicians inspect and test electrical motors after checking off all the items on the checklist.

- Collect the electric motors’ inspection findings.

- Make that there are no problems with load flow or power quality.

- Our experts will guarantee solutions to any problems that could occur.

- Check to see if the motor satisfies national efficiency standards.

- Provide a digital report that includes advice on safe work procedures.

Care Labs conducts motor acceleration study to confirm that the motor operates properly under conditions of maximum load and increases productivity (by mitigating the losses). Motor reliability is improved by lowering motor losses. We provide motor start analysis services in all major Hungarian cities, including Budapest, Debrecen, Szeged, and Miskolc for further details and a price on analysing the operation of industrial electrical motors, get in touch with Care Labs.

RELATED NEWS

How Are the Dependability and Performance of Commercial Motors Assessed? The easiest, most affordable, and fastest way to get consistent …

Hungarian Guidelines for Testing and Verifying Electrical Motor Efficiency In the global economy, industrial electric motors power a wide range …

The Importance of Load Flow and Short Circuit Analysis to a Hungarian Business Everyone is aware of how important energy …

Why Analysis of the Power System Considers Relay Coordination, Short Circuits, And Load Flow? To provide your facility with a …

Principles of Operation for the Power Quality in Hungary The performance and basic operation of the equipment connected to the …

How to Analyze the Power Quality in Hungary? The ability of equipment to use the energy supplied to it is …

Why Are Harmonic Why Are Harmonic Research and Analysis Research and Analysis So Crucial to Hungarian Businesses? Hungarian Businesses? Since …

Analysis of the Hungarian Power System’s Harmony: System’s Harmony: Power is a necessary component of life in the modern day. …

Hungarian Arc Flash Analysis: A Complete Guide A Complete Guide When a gas is exposed to a voltage that exceeds …

Analysis of Arc Flash Analysis of Arc Flash Hazards and Mitigation Techniques: Mitigation Techniques: Electrical arcs can develop when a …