Care Labs has authorized high, medium, and low voltage auditors to assist in the inspection of high, medium, and low voltage installations. Care Labs Conduct statutory audits to ensure the safe operation of facilities and to ensure compliance with laws, regulations, and rules.

Care Labs provides review guidelines for large projects to avoid unexpected delays in the review process and provides recommendations on what documents and reviews are needed.

In short, an electrical safety audit program is designed to prevent loss of productivity, any damage or losses to the property, and prevent loss of life or injury.

At Care Labs, experienced electrical engineers conduct comprehensive electrical safety audits to help customers reduce risks, use standard operating procedures for electrical equipment and help ensure compliance with applicable safety regulations.

The risk of death or injury due to electricity largely depends on where and how it is used. For example, the risk is higher, if used:

Certain types of equipment are also riskier than other types of equipment, such as:

Between 2003-15:

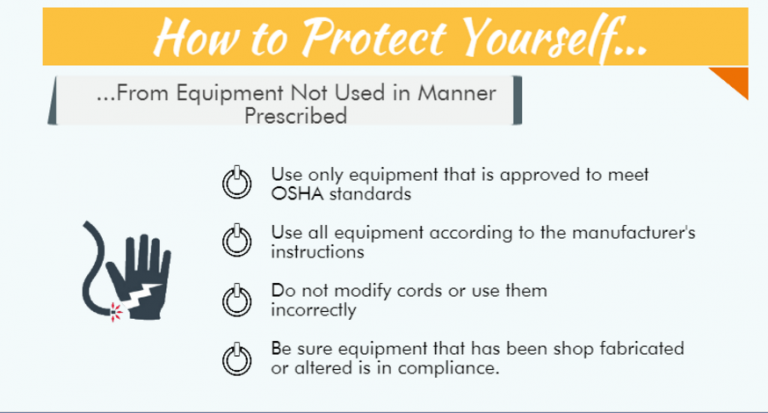

Electrical safety is very important to prevent electric hazards. This infographic summarizes all the preventive and safety measures of OSHA in terms of electricity.

If not properly done?

It may lead to:

The danger of electric shock continues to threaten the safety of people and property in the form of electric shocks, burns, injuries, fires, and explosions. Since electricity has become an indispensable part of our lives, it is necessary to effectively manage electricity risks.

In the processing industry, fires are extremely likely to occur due to electrical reasons, especially in industries that use flammable chemicals.

In the service industries like information technology, telecommunications, banking, and other commercial business enterprises, business operation interruption and loss due to risk of electric shock (fire in the server room, damage to expensive communication equipment, data loss, cable gallery fire, etc.) may be important. The solution is an electrical safety audit.

Generally, electrical equipment used under “adverse operating conditions” should be inspected at least once every 12 months. Other guidelines can be found in the manufacturer’s guidelines and Australian standards, such as:

AS/NZS 3760: 2010 Safety inspection during operation and testing of electrical equipment.

AS/NZS 5033: 2014 installation and Safety requirements for electrical equipment.

The legislative framework for electrical safety includes:

Several businesses invest in high-quality facilities, but smart businesses also pay attention to the safety and reliability offered by the facility. Electrical safety audit in Australia is a comprehensive approach to meet safety standards.

Care Labs offers a comprehensive Electrical Safety Audit service, which is conducted by our experienced electrical professionals who assist you in reducing risks, make use of standard operating procedures of electrical equipment, and help to ensure compliance with applicable national/ global Safety Standards and Regulations.

We offer electrical safety audit services in all the major cities of New South Wales, Queensland, South Australia, Tasmania, Victoria and Western Australia.

Book your electrical safety audit in Australia or get a quote today by contacting us!

From fault analysis to electrical safety compliance, we have the right solution for you at Care Labs.