Recent developments in technology & electronic devices are with nonlinear voltage-current characteristics, so generate harmonics....

ViewMotor Start Analysis in Canada

Motors are broadly used as an electric drive in various industrial applications like industrial motion control systems and to drive various machines, such as pumps, conveyors, fans, compressors as well as in main powered home appliances.

Starting a large motor, can cause severe disturbances to the motor, other connected loads in the network, and electrically remote loads from the motor starting. Care Labs helps you to identify the best of starting a motor and its impact on power system and connected appliances.

The main purpose of performing a motor start study includes:

- To check whether the starting motor can be successfully started under the operating conditions

- To recognize whether starting the motor will seriously affect the normal operation of other loads in the system.

Why Motor Start Study and Analysis is Done?

The starting torque will change or varies directly as the square of the applied voltage. Thus, excessive starting current results in a drop in terminal voltage which results in

- Low starting torques cause the failure of motor starting.

- Occurs unnecessary operation of under-voltage relays.

- Results in stalling of other running motors connected to the network.

- At the power source’s voltage, dips will occur and a consequent flicker in the lighting system takes place.

The most severe consequence of a large voltage drop is an increase in the current of all devices that servicing a constant load.

Static power supplies like computers and ballasts for lighting must rise the current to deliver the same quantity of power resulting in overheating and eventually burn-out.

Motor starting studies and analysis helps to assists in the choice of the appropriate motor design, the finest method of starting, and the correct system design for reducing the effect of the motor starting.

A motor starting study can be performed at the time of the design phase of the power system when it is still economically viable to create design modifications to verify that the system will achieve within the limits recommended by the utility.

Steps for Motor Start Analysis:

Step 1: Motor starting analysis starts at the consumer site to collect electrical supply data and historical information regarding the motor operation.

Step 2: With the measured data and information from the manufacturer are used to run the simulations.

Step 3: By using simulation software like ETAP, will help to calculate the operation for new installations and to diagnose problems. Moreover, it will provide solutions for existing motor installations.

Step 4: Apply both static and dynamic techniques to create the starting sequence of motors and normally depend on dynamic analysis to reconstruct the observed and measured starting conditions.

Motor start methods include:

- Direct on-line

- Capacitor assisted

- Resistor or inductor

- Open and closed transition auto-transformer starting

Soft starters with:

- Current ramp

- voltage ramp

- current limit

- Slip ring resistor insertion

- Manufacturer-supplied curves

- Open and closed transition Star Delta starting

Advantages of using soft starters are:

- Starting current can be controlled.

- Starting torque can be improved.

- Energy Saving is possible.

- Input power factor is increased.

- Minimizes transient during running conditions.

For Synchronous Motor Starting:

The several starting methods are:

- Across the line starting

- Shunt capacitor-assisted starting

- Resistor and/or inductor assisted starting

- Open or closed auto-transformer starting

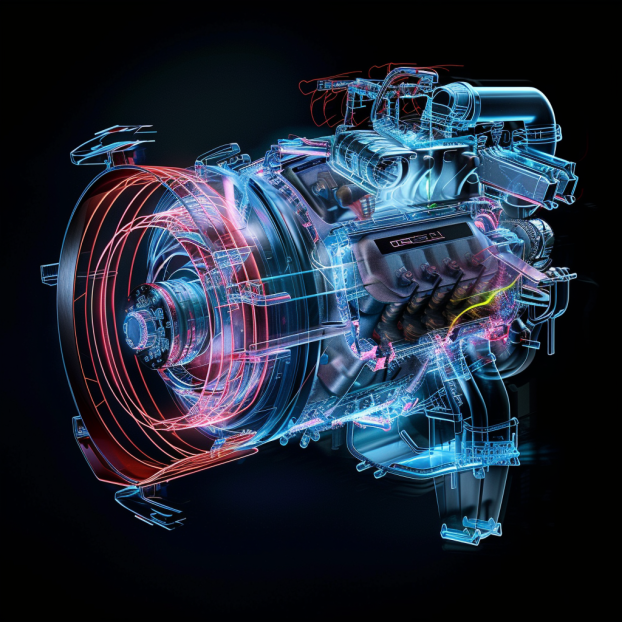

Motor Start Analysis using ETAP:

ETAP software provides two types of motor start analysis:

- Dynamic motor acceleration and

- Static motor starting.

In the Dynamic motor acceleration analysis, the motor starting can be demonstrated by dynamic motor modelling and the motor acceleration module can simulate the whole acceleration process of motor. This method is used to evaluate if a motor can be started and how much time is required for the motor to reach its rated speed, as well as to find the effect of voltage dips on the system.

In Static motor starting, the motor starting can be denoted by the locked-rotor impedance throughout its acceleration period, simulates the starting impact on normal operating loads. This technique is suitable for verify the impact of motor starting on the entire power system when the dynamic model for starting motors is not available. Dynamic motor acceleration calculations are used for analysis purposes.

As per the Canadian Electrical Code (CEC), the motor-related codes are Rule 28-012, Rule 28-014, Rule 28-016, Rule 28-504, Rule 28-506 these codes deal with the controlling, condition of the motor, method guarding motors, starters having different running and starting positions, safety, etc. Get advanced safety and service satisfaction from the leading professionals of the world. We offer electrical safety audit in Ontario, Quebec, Manitoba, Saskatchewan, British Columbia, Alberta and all the major states in the Canada. Contact us to get motor starting study and analysis services.