Arc Flash Risk Evaluation and Mitigation Are Essential.

Electrical arcs can form when a gas is exposed to a voltage greater than its ability to block. An arc forms when the voltage between conductors is sufficient to ionize the air between them. When ions are added to air, the air becomes an excellent electrical conductor. Air ionization produces a current that heats and lights the air. This heat causes the ionized air to rise, generating a stream in the shape of an arch. Therefore, the phenomenon is called an arch current. An arc flash can produce temperatures up to 20,000 degrees Celsius.

Arc flash risks pose a threat to both people and property. Among the advantages of arc in flash for businesses are:

- Direct expenses include medical care, rehabilitation, worker compensation, the cost of investigating the incident, and lost productivity.

- Indirect costs include legal and judgement expenditures, litigation costs, fines, insurance premiums, repair fees, and the cost of hiring a substitute worker.

- When undesirable events occur, they can hurt your image, make it harder to get employment, and even result in criminal charges.

- Most consumers will not connect with businesses that have a high number of accidents, resulting in lost income and perhaps the revocation of an electrical license.

- Mishaps involving the use of an electrical circuit Flash leaves an impression, which can lead to missed chances and wasted money.

Where Do Arc Flash Dangers Originate?

- Using the test probe on the improper surface

- Unsuitable equipment, installation, and work methods

- Utilizing inferior electrical components

- Insulation damage or equipment gaps

- Conflict with the disconnect panel

- Dust on electrical equipment or corrosion

- Lack of adequate maintenance of circuit breakers and switches

- Exposure of vital organs to the outdoors or fraying connections

- Wires carrying high voltage or a steady power source

- Dampness in electrical equipment

Methods for Decreasing the Risk of an Arc Flash:

- Deactivating electrical components:

It minimizes possible dangers as much as is practical. Work should not be conducted on electrified equipment, and great care should be taken while testing the equipment after it has been de-energized or after it has been re-energized. The use of remote tracking prevents circuit breakers from being too close to arc flash boundaries, which might endanger the worker using them.

- Utilize technologies that pose less risks:

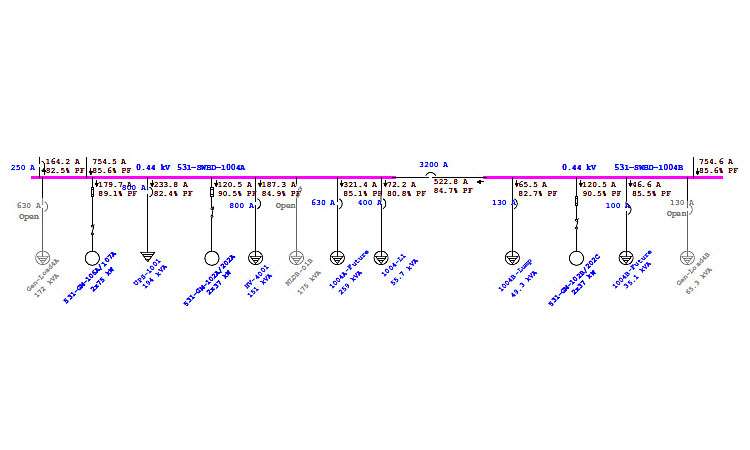

Arc flash analysis and power system studies are conducted to assess the risks involved with short circuits and the interaction of protective devices. Utilize low-threat alternatives, such as remote rack equipment, to protect people and property.

- To replace electrical and control systems:

Verify the availability of the necessary level of PPE (personal protective equipment) based on the intensity of the arc flash. Engineering techniques and tools are being changed to make them safer. Circuit breakers and energy distribution systems are meant to restrict the flow of energy.

- Reduce the fault current available:

By employing non-current limiting breakers, industries will be able to reduce the quantity of available fault current. These items can be utilized during maintenance with an exposed tie. The opening of the connection between dual power supplies during maintenance reduces arc flash dangers by limiting available fault current. Current-limiting reactors can be used to halt the flow of electricity during arc faults.

- Change the energy of the blast:

Promote the utilization of arc-resistant materials. Arc-resistant switchgear transmits the energy and heat released by arc flashes through ducts to an unoccupied area. This is accomplished by utilizing sealed joints, pressure relief vents on the top, and stronger hinges. Care Labs offers a vast array of investigation and analysis services for arc flashes. Experts investigate arc flash dangers to verify that your safety program is current. Care Labs can find potential arc flash dangers and minimize them using innovative technology. ETAP (Electrical Transient Analysis Program) software is utilized for research and analysis in Care Labs

Care Labs employs crew members in many places to guarantee that our specialists are close by in case of an emergency or routine work. Care Labs has rapidly established itself as an ISO 9001:2008-accredited company with a formidable reputation and a lengthy list of satisfied clients. Care Labs offers arc flash testing and analysis in all the major cities of Italy, including Rome, Milan, Florence, and Venice.

Share Post

Related Posts

-

Load Flow, Short Circuit, and Relay Coordination in Power System Analysis

-

Arc Flash Risk Evaluation and Mitigation Are Essential

-

How to evaluate efficiency and dependability of commercial motors?

-

Power Quality Working Principles in Italy

-

Arc Flash Analysis in Italy: A Detailed Guide

-

How to Conduct Power Quality Analysis in Italy

-

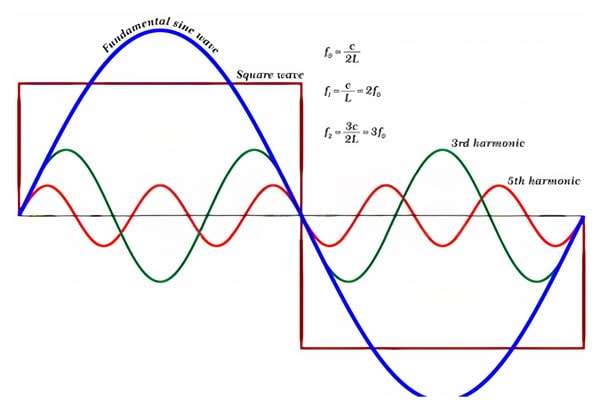

Why Is Harmonic Analysis and Research Important for Italian Businesses?

-

Harmonic Examination of the Italian Power System

-

Test and Verify Electrical Motor Efficiency in accordance with Italian Guidelines

-

The Importance of Load Flow and Short Circuit Analysis for a Italian Business