Arc Flash Study

Find Out What It's All About

CareLabs is an economical supplier of electrical arc flash analysis, investigation, and certification services for businesses of all types. Arc flash risks, employee training, paperwork, and PPE requirements will be assessed by skilled specialists to verify that your electrical safety program is up-to-date, compliant, and comprehensive. CareLabs is able to discover arc flash risks early on and take appropriate measures to mitigate the impact of harmonic distortions in order to ensure the safety of the equipment. ETAP (Electrical Transient Analysis Program) software is utilized to analyze and investigate Arc flashes.

What is Involved

The quantity of light and heat produced by an arc fault is called an arc flash. This occurs when current flows between conductors via an air gap. The arc flash ionizes the air and emits a considerable amount of light and heat (approximately 35,000 degrees Fahrenheit).

Arc flash analysis is the process of investigating and analysing the electrical installations of a facility in order to assess the incident energy available for each piece of electrical equipment. By creating safety criteria for competent electricians working on equipment and circuits, arc flash studies encourage safe working conditions. Included also are revised electrical one-line schematics and equipment locations, and a short circuit and coordination analysis.

Arc Flash Research Objectives:

- Determine the extent of damage produced by the incident energy emitted during an arc flash fault.

- Modifying the settings of protective equipment to reduce exposure to incident energy

- Issue safety recommendations for arc flash dangers.

- Adhere to the rules and laws specific to your nation.

- Determine the type of PPE worn on the job.

The Adverse Consequences of Arc Flash:

- Arcs inflict severe skin, facial, and eye burns.

- Gases and hot particles inhaled can cause severe internal burns to the throat and lungs.

- Injuries caused by flying debris and dislodged components

Arc flash studies are essential for lowering risks, boosting electrical employees’ safety, and the general safety of the business. Arc flash studies contribute to the identification of electrical hazard levels and the installation of suitable safety measures to limit the risk of burns and accidents. All utilities, manufacturing, industrial, and commercial businesses that use electrical disconnects, motor control, panel boards, and switchboards must do arc flash analysis.

Arc Flash Research Benefits:

- Enhanced human and mechanical safety

- Decreased medical and legal expenses

- Compliance with regulatory safety regulations

- Decreased number of code violations and penalties

For arc flash analysis, the following procedures are carried out:

- Data collection

- Conducting on-site verification

- Planning of a system

- Analysis of arc flashes

CareLabs Work Method Arc Flash Research

CareLabs delivers exceptional services and will provide any services requested by the construction team, local contractor, or engineering company.

Our work method is comprised of the subsequent steps:

- Data collection

- ETAP modelling of a power system

- Investigation of short-circuit

- An investigation on the coordination of overcurrent protection devices

- An investigation of arc flashes

- Conducting tests for arc flashes

- Maintaining records

- Methods for decreasing arc flash danger

- Full-size one-line diagrams

- Putting up arc flash labelling

- The finished report

Advantages of Using the Services of CareLabs:

- Develop more secure electrical systems that adhere to regulations and standards.

- Integrated modules for complete short circuit, overcurrent coordination, device assessment, and arc flash evaluation are combined with protective devices and bus ratings.

- Creating a more secure workplace

- Quick and easy alternative proposal for optimal design

- Increased safety margins through user-defined arc fault tolerances

- Save time by utilizing our computer-aided analysis to automatically generate arc flash labels.

- Reduce productivity losses and maintenance costs.

Crew members are strategically situated throughout CareLabs to ensure that our professionals are close by in case of a regular or urgent situation. CareLabs has rapidly established itself as an ISO 9001:2008-accredited business with a clientele that has supplied outstanding feedback. In addition to Brussels, Antwerp, Liege, and Ghent, we provide arc flash study and analysis services in all major cities. Contact us immediately for a complimentary estimate on arc flash research and analysis.

Related Services

Arc Flash Study

An arc flash study, also known as an arc flash hazard analysis, is a process of analyzing electrical systems to identify potential hazards related to arc flash events.

Power System Study & Analysis

Power System Study & Analysis service helps you to have a safe, reliable, and efficient power system for your facility under normal and abnormal circumstances.

Power Quality Analysis

Power quality analysis is the process of assessing the electrical power supply to ensure it meets the required standards for safe and efficient operation of electrical systems.

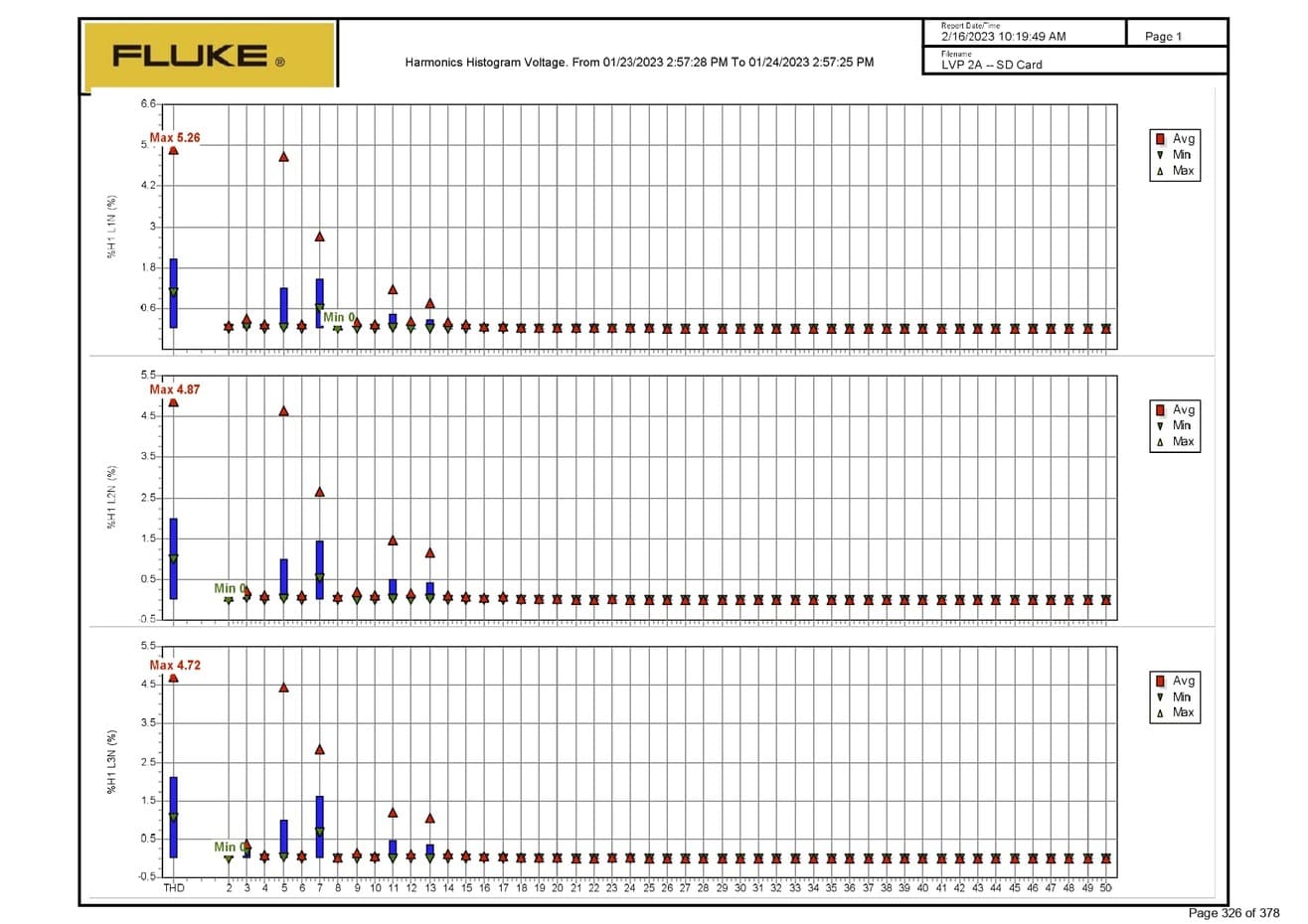

Harmonic Study and Analysis

Harmonic voltage analysis is a mathematical method for predicting potential resonances and harmonic distortion levels based on data.

Motor Start Analysis

Motor Start Analysis service helps you to get perspective on the best way of starting motor, and proper power system design for reducing the impact of the motor starting on the power system.