It can be defined as the approach that helps predict and prevent electrical hazards in a facility. In other words, instead of waiting for a fault to occur, the proactive safety approach focuses on early detection, and maintenance to prevent damage to the system and personnel.

“Care Labs emphasizes industries in Australia must adopt a proactive safety culture to ensure that your assets and people are always shielded from electrical hazards. Our power system analysis and solutions align with the safety goals and standards of an industry.”

Arc flashes are among the most dangerous electrical hazards, that can result in severe damages and even fatalities. A proactive safety approach identifies key areas of high arc flash risk using advanced technologies and methodologies. Hence, ensuring workplace safety with extensive arc flash study and analysis is imperative, especially in industries with complex electrical networks.

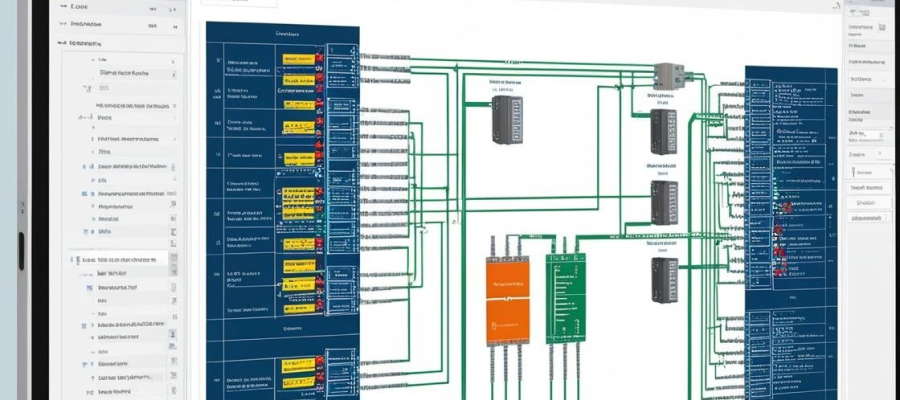

Arc flash assessments are power system analysis techniques to determine the potential levels of incident energy at various nodes in a network. This data helps understand the impact of an arc flash incident along with taking necessary safety measures like appropriate PPE, setting arc flash boundaries, and arc flash labels.

The study identifies high-risk areas by calculating the incident energy levels and safe working distances.

Arc Flash analysis evaluates fault currents, protective device settings, and equipment failures.

Following compliance standards like IEEE, OSHA, AS/NZS 4836, AS/NZS 3000, and AS 2067, helps maintain system reliability and prevent legal liabilities.

Arc Flash studies recommend appropriate PPE for personnel working near energized equipment. This helps prevent incidents due to human errors.

Thus, we can say that arc flash study is a proactive safety measure designed to identify and mitigate electrical hazards before incidents occur. The results of this study help organizations to implement risk mitigation strategies to protect their workplaces.

One of the greatest advantages of arc flash study is to educate the workers on arc flash hazards and protective measures. At Care Labs, we offer training support to employees in any facility. To top this, the use of advanced tools like ETAP helps us give comprehensive arc flash study reports that give insights to make informed decisions.

By embracing a proactive approach to arc flash safety, Australian industries can:

Care Labs is a power system consulting and project management company. We have a well-experienced team of electrical engineers who are trained in providing expert power system analysis solutions in Australia. We adhere to compliance standards for electrical safety which makes our solutions highly-appreciated in the domain.

Arc Flash study is a proactive safety measure to reduce arc flash risks in facilities that have extensive electric networks. Implementing these solutions and adopting the best practices and strategies can bring significant and long-term benefits.

Partner with Care Labs to protect your facility’s critical assets and leverage our expertise to implement safety measures tailored to Australian standards.

Get a Free Quote today!

From fault analysis to electrical safety compliance, we have the right solution for you at Care Labs.