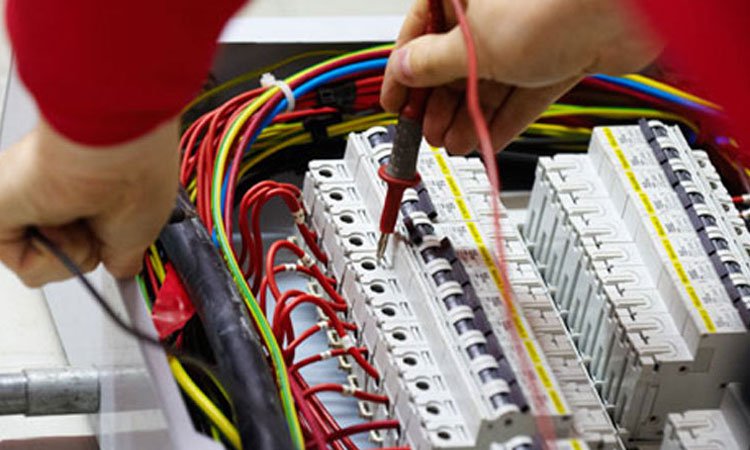

All electrical installations deteriorate over time making it widely prone to faults, fires and electric shocks. To avoid such electrical hazards, it’s always preferred to carry out electrical safety inspections from time to time. An electrical inspection refers to the thorough check-up of all electrical wiring, connections and installations at a residence.

Care Labs offers an all-inclusive commercial testing and inspection service for your business to ensure all electrical systems and appliances are working safely and efficiently. This service comprises of checking the condition of electrical installations and equipment at your premises.

The main objective of carrying out electrical inspection is to prevent harm of life, possessions and valuables. Given the vital importance of electrical inspection, it is mandatory to adhere to electrical safety standards laid out in the province. The National Electrical Code (NEC) is the standard code for electrical safety.

What is a Commercial Electrical Inspection?

Commercial spaces such as offices, factories, shopping complexes and restaurants have a higher public inflow and ensuring safety of the public is the key responsibility of the owner.

A commercial electrical safety inspection is recommended for the safety of you and your employees as it checks all electrical systems for necessary maintenance, electrical damages, overloads, repairs and out of code wiring with relevant NEC standards.

Why are Commercial Electrical Safety Inspections so important and why you need to get it done?

- Electrical overloads – one of the most prominently occurring issue that normally goes unnoticed until there is a tripping of the circuit breaker or any other visible damage. Having a commercial electrical inspection can help identify electrical points where the system may be overloaded and thus, provide the required recommendations for smooth operations.

- It is always a best practice to ensure that all electrical systems are properly maintained and installed professionally to minimize chances of electrical hazards. Commercial electrical inspection ensures to eliminate potential threats and aids in determining critical defects that might cause problems.

- Commercial electrical inspections are also highly recommended for those looking to purchase a new building. Older buildings are susceptible to being outdated, not meeting the given standards, and having electrical damage far greater than newer buildings. So, while purchasing a new building, make sure that you get an electrical inspection first.

- Since the construction of the building numerous repairs and replacements would have been performed by various technicians from various companies. It’s recommended that you find a good company and stick with the same one on a long-term basis, to ensure consistency and thoroughness when maintenance, repairs, and other work is done in the future

Commercial inspection checklist and services:

The checklists are planned to help inspectors keep track of the various aspects of an electrical installation that must be examined for NEC compliance. The checklist also serves as an organizational tool for contractors and project managers to carry out self-inspections. Inspections are usually carried out in two phases; A series of rough or general inspection and final inspection. A building must pass both the phases before it can be occupied.

General safety Inspections is the basic hazard analysis and includes inspection questions like – Does the inspection task involve exposed energized conductors or circuit parts? Can the risk of this exposure be justified? Where are the boundaries for shock protection? Etc.

The General requirement of Electrical inspection include:

- Identifying installations or parts of installations that are covered by the NEC. 90.2(A) and (B)

- Verify that all installations are according to the instructions provided in the listing and labelling of materials and equipment. NEC 90.7, 110.3(B)

- Verify that interrupting and SC current ratings are satisfactory for the conditions of the installation. NEC 110.9, 110.10, 110.24.

- Verify that all unused openings are closed well. NEC 110.12(A), 408.7

- Check for damaged/unrepaired parts and contamination caused by the use of foreign materials NEC 110.12(C)

- Check for solid mounting and ventilation. NEC 110.13

- Check for proper use, temperature and electrical ratings of terminations and splices. NEC 110.14(A) and (B)

- Check for enclosure markings and verify ratings of the surrounding environment. NEC 110.28

- Verify satisfactory working clearances, and adequate headroom around the equipment. NEC 110.26(A) and (E)

- Check for switching circuits and circuit directories for switchboards, panel boards and similar equipment

Further inspection is performed based on the type of electrical installation. Main categories of which are-

- Wiring methods and devices:

- Identifying the wiring method sand verifying it’s aptness for the

- To check if all conductors of a circuit are bundled together

- To check insulation standards, insulating bushings and grommets.

- To check for spacing from edges of frames and from nails and screws

- Verifying that cable trays& raceways are used solely for electrical conductors

- Services, feeders and branch circuits

- Verifying that each structure has only one service line. If more than one, the presence of additional services is justified.

- Checking clearances from building openings, roofs, swimming pools and other structures.

- Grounding and Bonding

- Identify the type of grounding electrodes present on site.

- Verify the size of grounding electrode conductor and ensure they are protected and secured.

- Check for proper connections and grounding of the related enclosures and wiring methods for installations with grounding conductors.

- Dwelling units and Manufactured home sites

- Special occupancies

- Emergency, standby systems and fire pumps.

The checklist of an electrical safety inspector is exhaustive. By hiring a professional from Care Labs, will help you take load off of your shoulders and ensure that everything at your company is up to code and in line with state regulations.

Care Labs offers our services in California, New York, Illinois, Ohio, Texas, New Jersey, Pennsylvania, Georgia, Washington, Florida, Massachusetts, Michigan, North Carolina, New Mexico, Virginia, and all the major states and cities in the United States of America.

Book your commercial electrical safety inspection or get a quote today!

The Importance of Relay Coordination in Power System

Introduction Relays are protective elements that help control faults in a power system. Proper relay coordination helps isolate the fault sections from healthier sections in a power system. Being a fundamental part of ensuring reliability and operational continuity, the strategic configuration of protective relays is imperative in the design of a power system. One way […]

Which of these Facts About Arc Flashes are True?

Introduction In electric hazards, arc flashes are among the most dreadful threats. Despite their criticality, many myths surround arc flashes. Although IEEE and NFPA continuously strive to enhance awareness, five to ten arc flashes happen in the USA daily. We, at Care Labs understand the importance of maintaining a healthy electrical infrastructure. To help companies […]