Taiwanese Arc Flash Analysis: A Comprehensive Guide

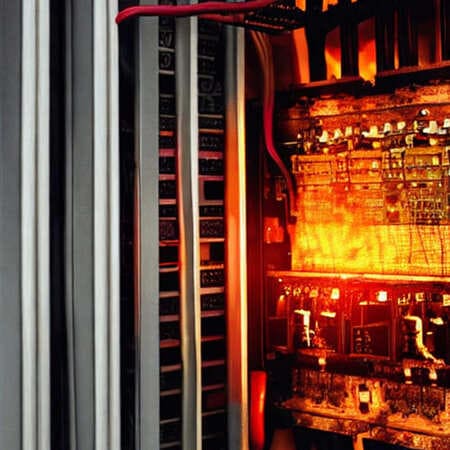

When a gas is exposed to a voltage greater than its insulating properties, electrical arcs result. The arc is initiated when the voltage is sufficient to ionize the air between the conductors.

- When a gas is ionized, it becomes a good conductor, allowing current to flow and producing the arc-shaped current called arc flash.

- An arc fault is an electrical discharge that occurs unintentionally and causes a fire.

- During an arc burst, toxic gases are emitted.

Arc flash hazards may have disastrous consequences for businesses and electrical infrastructure.

- Additional expenditures for medical treatment, rehabilitation, and worker compensation, in addition to costs connected with accident investigation and production downtime.

- Legal expenses and judgements associated with litigation, fines, insurance premiums, repair fees, and replacement worker expenses.

- Negative impact on the name and reputation of the firm

- Loss of business opportunities due to a history of accidents, which may result in the cancellation of an electrical license.

Table of Contents

The Following Brings About an Arc Flash:

- Conductor insulation failure

- Exposed live parts

- Human negligence

- Improper switch and circuit breaker maintenance

- Water near equipment

- Obstructed disconnect panels

- High-voltage cables

- Electrostatic discharge

- Damaged tools and equipment

Methodology for Evaluating an Arc Flash:

Arc flash dangers can occur whenever high-voltage or low-voltage, high-current switching happens.

Determine the arc flash risk:

- Conduct an arc flash/fault analysis or study, including data collection, software-based power system modelling, short circuit analysis, overcurrent protective device coordination study, arc flash analysis, and arc flash evaluation.

- Evaluation of the likelihood that a worker may be exposed to an arc flash

React to the risk:

- Requiring interaction with only de-energized equipment to reduce worker exposure to arc flash hazards.

- Automated systems are superior to their manual counterparts.

- Protect personnel from potential threats by installing physical barriers between them and energized equipment.

Control of engineering operations:

- By lowering fault current, you may reduce incident power.

- Detection and prevention techniques for arc flashes

- Automated systems and remote controls

- Switchboard improvement or modification

- Installation of permanent circuit breakers

- Insulation of bus bars

- Replacement of blown fuses

Administrative controls:

- Labeling switch rooms, plants, and other pertinent places with incident energy levels.

- Labeling arc perimeters

- Documenting arc flash information and diagrams.

- Implementing safe processes and policies to limit exposure

- Implementing incident energy and PPE (Personal Protective Equipment) levels

Personal protective equipment (PPE):

- Personal protective equipment, although being the least effective, can mitigate an accident’s severity but cannot prevent it. The selection of personal protective equipment (PPE) is based on the energy levels of the incident.

CareLabs provides a solution for all arc flash-related risks. Professionals with the necessary training and expertise can analyze the potential for arc flash risks and provide suitable mitigation and control techniques to safeguard your personnel and property.

Advantages of Using CareLabs Service:

- Power systems that are more secure in accordance with government rules and standards.

- Fully integrated electrical systems are cost and time effective.

- Create a safer workplace environment.

- Provide quick alternatives in the event of an emergency.

- Enhance safety margins

- Save time by manufacturing arc flash labels and work permits automatically.

- Avoid potential penalties and legal expenditures.

This guideline emphasizes the accumulated information and experiences about the hazards of electric arc flash. It outlines the control hierarchy for arc flash management. It includes a variety of arc flash control procedures, such as de-energizing electrical equipment, IR thermography, and racks. CareLabs has staff members stationed in several areas to guarantee that our specialists are easily reachable in the case of a routine or urgent situation. CareLabs established itself as an ISO 9001:2008-accredited company very rapidly, and it has since gathered a customer with a good reputation and good comments. In all major cities, including Taipei, Kaohsiung, Taichung, and Tainan, CareLabs provides arc flash analysis and investigation services.

RELATED NEWS

Coordination

RELATED NEWS