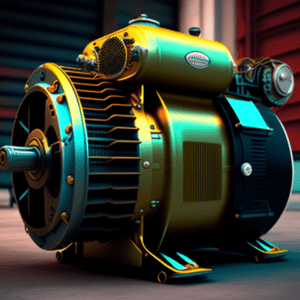

Check and Test the Performance of Electric Motors According to Taiwanese Rules

In the global economy, industrial electric motors power a vast array of uses. The automobile industry is responsible for up to 70% of all energy used in industrial settings, 35% of all energy used in the commercial and service sectors, and 45% of all electricity produced worldwide, according to the International Energy Agency (IEA). The fact that motor-related downtime costs thousands of dollars per hour highlights the significance of electric motors in a range of industrial applications. They are responsible for most greenhouse gas emissions and environmental deterioration caused by power plants.

In addition, they are responsible for the fast-rising demand for electricity in developing countries. There exists a global economic potential to boost the energy efficiency of industrial motors by 20 to 30 percent, with typical payback times of less than three years. Electric motors account for 15%, or 4.3 billion tons, of the world’s annual carbon-CO2 emissions of 26 billion tons. Increasing energy efficiency is one of the most cost-effective and low-risk ways to minimize the rising demand for energy and greenhouse gas emissions.

Utilize an efficient motor because of the following:

- Lower operating expenses

- Cooler and quieter performance

- Enhanced durability and dependability of motors

- Reduced greenhouse gas emissions

Table of Contents

Starting with the Motor Analysis:

Some of the energy received by electric motors is lost due to friction, windage, and stator, rotor, and magnetic core losses. These losses are responsible for the decrease in motor efficiency. Considering energy consumption and industrial usage of electric motors, the necessity and importance of efficiency evaluation and minimum energy performance standards are evident. The chosen test method affects the precision with which motor efficiency and motor loss are determined. There is no one testing procedure used widely across all industries. Despite being a basic concept, evaluating and validating the motor’s energy efficiency using the various criteria can be difficult.

Techniques Globally Acknowledged for Gauging Performance:

The following testing methods are frequently mentioned in industrial applications:

IEEE 112-2004 is a typical motor and generator testing procedure. 2014 edition of Tests, International Electrotechnical Commission (IEC) publication 60034-2-1. Methodologies for estimating the efficiency and losses of electrical spinning equipment. JEC 37 is the standard developed by the Japanese Electrotechnical Committee for induction devices. IEEE Standard 112-2004

This methodology includes 10 energy efficiency testing methodologies. To utilize the most essential:

- Simple testing of inputs and outputs

- Evaluate loss-separated input and output.

- Test for back-to-back machine separation loss.

- Determination of load losses using smoothed residual losses

- The Eh-star technique

For the IEC standard test, three main categories exist:

- Determining the input-output power of a single device.

- Measuring the input-output power of two connected-in-series devices.

- One machine’s losses were measured.

The additional load losses are completely disregarded by the test procedures for Japanese standard JEC 37. Increasing the energy efficiency of equipment and appliances provides several significant economic and environmental benefits, including reduced operating expenses for businesses. We provide motor start analysis services in every major city in Taiwanese, including Taipei, Kaohsiung, Taichung, and Tainan.

Methods for Evaluating the Performance of Electric Motors:

- Before performing the audit, we gather and review any paperwork pertaining to the location.

- Create a one-line diagram and a check list to enhance your reputation.

- Using the inspection checklist for electrical motors, continue the audit.

- After completing the check list, the specialists test and evaluate the electrical motor.

- Obtain the electric motor’s inspection results.

- Examine the load flow and power quality for any potential issues.

- If difficulties develop, our experts will guarantee that they are resolved.

- Determine if your engine fulfils national performance requirements.

- Provide a digital report with safety recommendations.

CareLabs performs motor acceleration testing to ensure that the motor performs best under high-load circumstances and that productivity is maximized (by mitigating the losses). The removal of losses also improves the reliability of motors. We provide motor start analysis services in Tokyo, Yokohama, Osaka, and Kyoto, among other important cities. Contact CareLabs for business electric motor efficiency auditing and a quotation.

Among the Advantages of Power System Analysis Are the Following:

- The electricity infrastructure has been upgraded.

- Using the proper equipment with the appropriate power rating.

- Electrical dangers will be less dangerous and safer.

- Adhere to all relevant electrical installation regulations and legislation.

- The proposal of several techniques to improve the system’s performance and dependability.

- For future inspections, a record of the current state of the power system is preserved.

CareLabs provides Load Flow analysis, Short Circuit analysis, and Relay coordination analysis to monitor the voltage at various buses in addition to the actual and reactive power flow between buses, analyze the system under various fault conditions, and determine how well the system handles small and momentous changes. If your company in Japan need an audit of its power system, please contact us, or request a quotation We will contact you within 24 hours by one of our customer service specialists.

RELATED NEWS

Coordination

RELATED NEWS