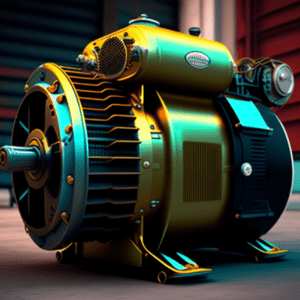

Check and Test the Performance of Electric Motors According to Korean Rules

Worldwide, industrial electric motors are employed in many applications. The International Energy Agency (IEA) estimates that the automobile industry uses up to 70% of industrial energy, 35% of commercial and service energy, and 45% of global power. Electric motors are essential in many industrial applications since motor failures cost thousands of dollars per hour. They create most climate-altering greenhouse gases. Additionally, they are primarily responsible for developing nations’ rising power demand. Global economic potential to boost industrial motor energy efficiency by 20% to 30% exists with most payback times under three years. Electric motors emit 4.3 billion tons of CO2 yearly, 15% of the 26 billion tons worldwide. Energy efficiency is a cheap and safe technique to reduce greenhouse gas emissions and moderate energy usage.

Make use of a reliable motor since:

- Reduced operating expenses

- A less noisy and cooler run

- Improved performance and durability in motors

- Less greenhouse gases are released into the environment.

Table of Contents

How to Begin an Evaluation of a Motor:

Electric motors do not typically transform all the electrical energy they consume into mechanical energy. Friction, windage, and losses in the stator, rotor, and magnetic core are the main sources of energy loss. The motor’s efficiency is being reduced by these losses. It is simple to see why and how crucial it is to assess efficiency and establish minimal energy performance criteria when one considers how much energy is lost and how electric motors are used in industry. Depending on the testing technique used, efficiency and motor loss can be calculated with varying degrees of precision. Every company in the world uses a similar testing method. Although the concept is straightforward, it can be difficult to measure and validate a motor’s energy efficiency using several criteria.

Internationally Recognized Methods for Evaluating Efficacy:

The following testing processes are frequently mentioned in industrial settings:

A common test method for multiphase motors and generators is IEEE (Institute of Electrical and Electronics Engineers) 112-2004. Publication 60034-2-1 by the International Electrotechnical Commission (IEC), 2014. ” . calculating the effectiveness and losses of electrical spinning gear. The Japanese Electrotechnical Committee developed JEC 37 as a standard for induction devices. ANSI/IEEE 112-2004 ANSI/IEEE 112-2004

Ten techniques are included in this approach for assessing energy efficiency. To emphasize what is most important:

- There are easy input and output tests.

- Input and output testing using loss separation.

- Testing in parallel on two linked PCs

- The load losses are calculated using smoothed residual losses.

- Eh-star technique

There are three primary IEC standard testing categories:

- Figuring out a machine’s input and output power.

- Monitoring the flow of electricity between two devices that are linked side by side.

- One machine had losses, which were totaled.

The Japanese JEC standard 37 test procedures entirely disregard the increasing load losses. Businesses may conserve energy and money by reducing the amount that their machinery and appliances consume. This is only one of many important economic and environmental advantages. We provide motor start analysis services in Seoul, Busan, Incheon, Daegu and Gwangju, among other important cities.

RELATED NEWS

Coordination

RELATED NEWS