Korean Arc Flash Analysis: A Comprehensive Guide

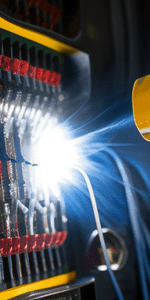

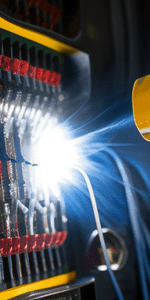

Electrical arcs form when a gas is exposed to a voltage greater than the voltage it can block. The arc starts when the voltage is high enough to ionize the space between the conductors. When a gas is ionized, it turns into an excellent conductor, allowing current to flow and producing an electrical “arc flash” with an arched form. An unexpected electrical discharge is an arc fault.

- Elevated temperatures cause arc flashes to produce blinding brightness and loud noise.

- A high-pressure wave known as an arc blast has the potential to launch molten metal and tiny metal particles into the air.

- Noxious vapors

Arc flash hazards might be disastrous for commercial structures and electrical infrastructure. Here are a few examples of company losses brought on by arc flash hazards.

- Additional expenses for health care, therapy, workers’ compensation, accident investigation, and lost output.

- Legal fees, penalties, insurance premiums, repair costs, and the expenditure of employing a replacement employee associated to a lawsuit.

- A detrimental effect on the brand and reputation of the company.

- Loss of business opportunities brought on by a history of accidents that might result in the termination of an electrical license.

Table of Contents

The Arc Flash Is Caused by the Following:

- Deteriorated insulation on a conductor

- Body parts that are on display

- Human beings are careless

- Inadequate switch and circuit breaker maintenance

- The instrument is near to the water.

- Any obstacles should be taken out of the way.

- Wiring for high voltage

- Electrostatic charge discharge

- Instruments and equipment in bad shape

Arc Flash Analysis Technique:

Anytime high-voltage or low-voltage high-current switching takes place, there is a possibility of an arc flash.

Identify the likelihood of an arc flash:

- Collect data, model the power system using software, analyze short circuits, learn how overcurrent protection devices interact, analyze arc flashes, and evaluate arc flashes as part of an arc flash/fault study or analysis.

- Estimating the likelihood that a worker may be hurt by an arc flash

React to the danger:

- If employees exclusively contact off-the-grid equipment, they are less likely to sustain arc flash accidents.

- Automated systems would be preferable to manual ones in use.

- To protect employees from any active equipment, install physical barriers between them.

Engineer control:

- To reduce incident energy, decrease the fault current.

- Arc flash detection and suppression systems

- Switches and remote controls

- Improvements or changes to the switchboard

- Circuit breakers that fail to trip

- Insulation for bus bars is important.

- Replace blown fuses.

Administrative controls:

- Locating energy levels by marking switch rooms, plants, and other important locations

- Taking note of the arc’s boundaries

- Sketching up arc flash diagrams and taking notes

- Putting in place secure guidelines and practices to reduce vulnerability

- PPE (personal protective equipment) levels and incident energy

Personal protection equipment (PPE):

- Although it is the least effective PPE, it may lessen an accident’s severity but cannot stop it. The type of personal protection equipment (PPE) used depends on how serious the issue is.

You can get assistance from CareLabs with any arc flash-related issues. Experts with extensive training and understanding can identify arc flash dangers and provide the best mitigation and control strategies to guarantee the safety of your staff and property.

The Advantages of CareLabs' Service Include:

- Safer electricity systems that adhere to regulations and criteria

- Working to your full potential helps you save time and money.

- Bolster workplace safety.

- In case of emergency, give immediate options.

- Raising the safety margins

- To save time, produce arc flash labels and work permits automatically.

- Avoid penalties and legal costs by taking precautions.

This strategy is based on what has been done to avoid electric arc flashes and what is known about their risks. It talks about the arc flash management control sequence. It includes several methods for avoiding arc flashes, including turning off electrical devices, using infrared thermography, racking, etc. To ensure that our professionals are available nearby in the event of an emergency or normal work, CareLabs employs crew members in many locations. CareLabs quickly attained ISO 9001:2008 certification and built a clientele with a solid reputation and positive reviews. Seoul, Busan, Incheon, Daegu and Gwangju are just a few of the main cities where CareLabs provides arc flash testing and analysis services.

RELATED NEWS

Coordination

RELATED NEWS