What is it?

Power quality analysis checks the power supply for safety and efficiency.

Years of experience?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus

Terms of service?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus,

Electrical Standards

LRED

LRED

LRED

LRED

LRED

LRED

LRED

LRED

LRED

LRED

LETS DISCOVER MORE

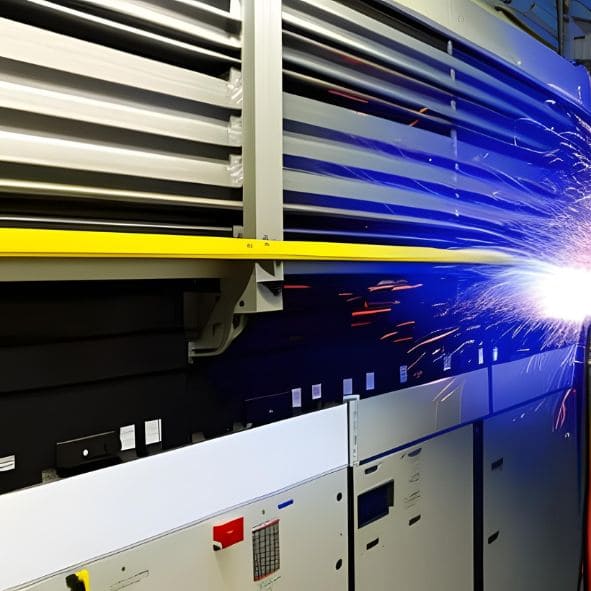

CareLabs offers low-cost analysis, investigation, and certification services for electrical arc flash in a range of sectors. Certified professionals will analyze the arc flash hazards, employee training, documentation, and PPE (Personal Protection Equipment) requirements to ensure that your electrical safety program is current, compliant, and exhaustive. CareLabs may discover arc flash risks early and perform the appropriate actions to mitigate the impact of harmonic distortions to ensure the equipment’s safety. ETAP (Electrical Transient Analysis Program) software is used for the analysis and study of Arc flashes.

The arc flash is the amount of light and heat produced by an arc fault. This occurs when current flows via an air gap between two conductors. The arc flash ionizes the surrounding air and emits a considerable amount of light and heat (approximately 35,000 degrees Fahrenheit). Arc flash analysis is the research and evaluation of the electrical systems of a facility to determine the incident energy available for each piece of electrical equipment. Arc flash studies improve workplace safety by detailing the safety criteria for electricians who operate on equipment and circuits. In addition, updated electrical one-line diagrams and equipment locations as well as a short circuit and coordination analysis are provided.

Research Goals for Arc Flash:

- Determine the level of damage resulting from incident energy emitted during an arc flash fault.

- Adjusting protective equipment settings to limit exposure to incident energy

- Develop rules for arc flash safety.

- Observe the laws and standards of your country.

- Determine the type of PPE utilized on the job.

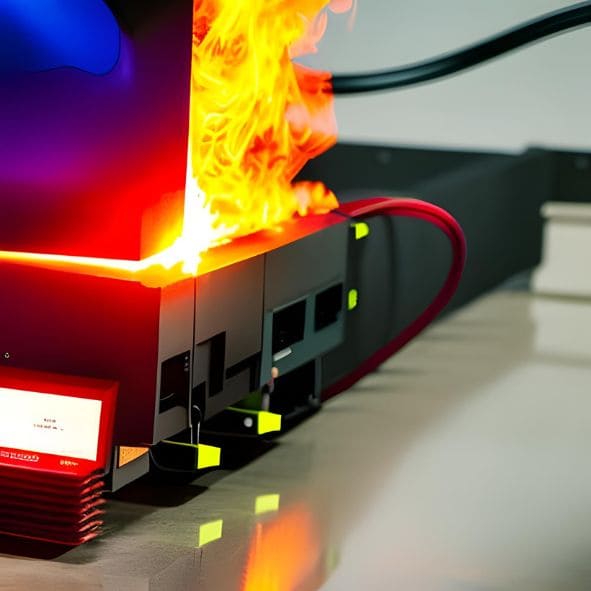

The Negative Effects of Arc Flash:

- Arcs produce severe burns to the skin, face, and eyes.

- Inhaling gases and hot particles can cause serious burns to the throat and lungs.

- Accidental injuries resulting from flying debris and unsecured pieces

Arc flash studies are vital for reducing hazards, enhancing the safety of electrical people, and the organization’s general safety. Arc flash research contributes to the evaluation of electrical hazard levels and the adoption of appropriate safety measures to reduce the risk of burns and accidents. Arc flash analysis is required for all utilities, manufacturing, industrial, and commercial enterprises that utilize critical electrical components, such as electrical disconnects, motor control, panel boards, and switches.

The Benefits of Arc Flash Research:

- Improved human and machine safety

- Medical and legal expenses are reduced.

- Compliance with regulatory standards for safety

- Reduced standard infractions and punishments

The steps involved in arc flash analysis are as follows:

- Acquisition of Knowledge

- Field verification

- System design

- Exploration of arc flashes

CareLabs Work Procedure:

CareLabs provides exceptional services and will provide any services requested by the construction crew, local contractor, or engineering firm.

Our method of conducting business comprises of the following steps:

- Acquisition of Knowledge

- ETAP is applied for power system modelling.

- Short-circuit analysis

- Coordination of overcurrent protection

- An analysis of arc flashes

- Arc flash assessment

- Keeping a record

Methods to reduce the possibility of an arc flash:

- Full-size one-line diagrams

- Currently, arc flash indications are being added.

- The finished report

Advantages of Using CareLabs' Services:

- Develop power systems that adhere to established rules and criteria.

- Protective devices and bus ratings are paired with integrated modules for thorough short circuit, overcurrent coordination, device assessment, and arc flash evaluation.

- Developing a safer workplace

- Simple alternative design proposal

- Utilization of user-defined arc fault limits increases safety margins.

- With our computer-aided analysis, you may save time by automatically developing arc flash labels.

- Reduce lost productivity and maintenance costs.

Crew members are assigned to various areas throughout our CareLabs, ensuring that our experts are never too far away in the event of a routine or urgent problem. CareLabs has quickly established itself as an ISO 9001:2008-accredited company whose customers have given excellent feedback. We provide investigation and analysis services for arc flash in all major cities, including Tokyo, Yokohama, Osaka, and Kyoto. Contact us right now for a free quote on our arc flash investigation and analysis.

RELATED SERVICES