How to evaluate efficiency and dependability of commercial motors?

The cleanest, most affordable, and quickest approach to delivering dependable electricity is to increase energy efficiency. Around 46% of all electricity and 69% of all energy used in the industrial sector is used by motors. One of the key issues that many companies face is energy consumption. The biggest problem that has to be solved is the inefficient architecture and power consumption. The main causes of high energy costs and challenges in supplying the rising demand for power are poor design and inefficient use. Most motors operate between 50% and 100% of their rated load, but around 75% of that load, they are most effective. As the motor ages, its efficiency starts to decline. An electric motor’s efficiency starts to decline automatically at 50% load.

A Motor's Performance Is Influenced by Four Factors:

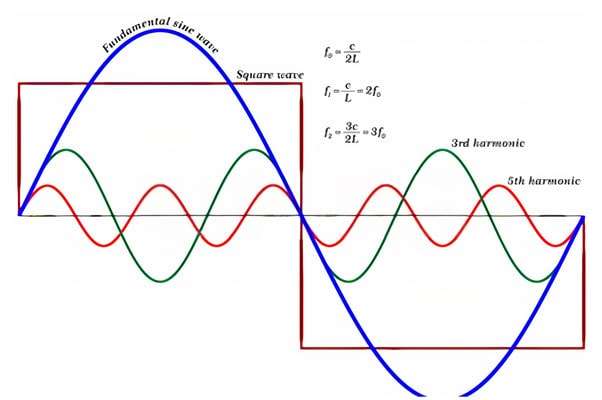

- Poor power quality has a direct impact on a motor’s operation. Transients, imbalances, sags, swells, and harmonics can all lead to severe damage and, in extreme cases, result in the motor ceasing to function.

- When a motor produces rotational force to propel a mechanical load at the rated speed of the spinning shaft, torque is produced. The running of the electric motor at the appropriate frequency and torque speed ensures its dependability. An electric motor’s performance may be assessed by measuring torque.

- This section explains the workings of an electric motor and what to anticipate from it. A motor’s connections, bearings, and insulation are stressed when it is mechanically overworked. This has an impact on the motor’s performance and might cause it to stop working or die earlier than expected.

- In conclusion, a motor’s effectiveness directly affects the bottom line. The gathering of baseline data is the first step in predictive and preventive maintenance.

Seventy-five percent of industrial motor failures each year result in production downtime of one to six days. 36% of motor failures occur within a day and 90% happen within a month of a warning. To prevent motor failure and operational issues You can prevent issues and enhance your electric motors’ dependability and performance by routinely evaluating, analyzing, inspecting, and auditing them.

Data on Motor Performance:

Over a 53-year period, raise the efficiency of an induction motor by 68%. (1960 to 2013). Over the course of a year, electric induction motors’ efficiency will increase as losses decrease. An induction motor’s energy usage has decreased over time (statistics for a 45 kW, 4p type motor). CareLabs evaluates electric motor reliability and efficiency in a variety of commercial and industrial situations. We examine and pinpoint the issue so you can stop losing money and increase motor effectiveness. Our aim as informed and professional technicians is to provide our customers with outstanding service.

CareLabs' Services Have the Following Advantages:

- We are always accountable for our deeds.

- Service your customers with excellence.

- Be as prompt as you can while responding to chats.

- Our team is strengthened by having an experienced and dependable electrician.

- Knowledge of Spanish norms.

- Choose a time that works for you.

- Give you a thorough digital report to make sure you are satisfied.

Techniques for Measuring the Performance of Electric Motors:

- We gather and review all site-related paperwork prior to the audit.

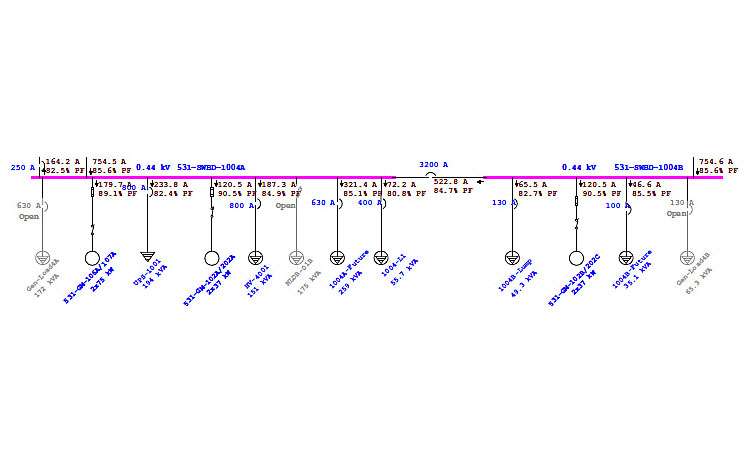

- To advance your position, make a one-line schematic and an inspection list.

- Utilize the inspection checklist for electrical motors to continue the audit.

- After completing the check list, the experts evaluate and inspect the electrical motor.

- Obtain the electric motor’s inspection findings.

- Check for any issues with the load flow and the quality of the electricity.

- If issues do develop, our experts will see to it that they are fixed.

- Check to see whether your motor satisfies national performance requirements.

- Send a digital report with advice on safety.

CareLabs does motor acceleration tests to make sure the motor performs well under heavy loads and that productivity is increased (by reducing losses). Eliminating losses also increases the reliability of motors. We offer motor start analysis services in Madrid, Barcelona, Valencia, and Seville among other important cities. For a price and to audit the effectiveness of industrial electric motors, get in touch with CareLabs.

Share Post

Related Posts

-

How to Conduct Power Quality Analysis in Spain

-

Power Quality Working Principles in Spain

-

The Importance of Load Flow and Short Circuit Analysis for a Spanish Business

-

Test and Verify Electrical Motor Efficiency in accordance with Spanish Guidelines

-

How to evaluate efficiency and dependability of commercial motors?

-

Arc Flash Analysis in Spain: A Step-by-Step Guide

-

Load Flow, Short Circuit, and Relay Coordination in Power System Analysis

-

Why is Harmonic Analysis and Study Important for Spanish Businesses?

-

Importance of Arc Flash Hazard Analysis and Mitigation Methods

-

Harmonic Analysis in Power System in Spain