An electrical switchgear risk assessment is relevant in any circumstance one works with live parts, power tools, or electric circuits. So, for safe work practice, workplaces will need to carry one out.

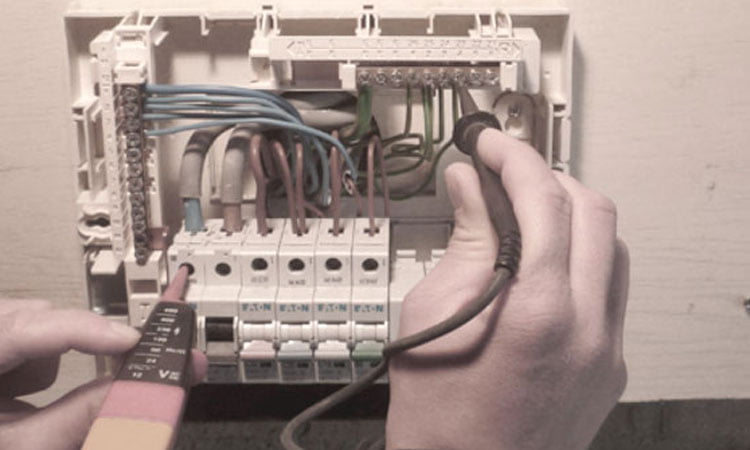

Electrical equipment and electrical switchgear risk assessment is a planned and scheduled event to help ensure a safe and reliable electrical system. It is used to assess and manage hazards within your facility.

Care Labs is providing electrical installation study, testing, inspection, and certification services, and offering risk assessment services for electrical equipment.

As an employer are responsible for electrical equipment’s safety in the workplace, regular inspection, test, and maintenance practice are advisable.

Electrical shock has the potential to cause severe injury or even fatality!

As per statistics

- 25% of overall fires occur due to electricity (NFPA)

- 411 deaths from work-related electrical accidents per year (NIOSH)

- Electrocution – the fifth major cause of death (NIOSH)

Electrocution causes merely 7% of all workplace deaths

Electrical accidents- occurs due to:

- Lack of equipment safeguards

- Avoiding safety practices

- Lack of training on it

- Lack of maintenance

- Signs of water getting in

- Signs of unauthorized access or interference

- Abnormal conditions

- Rough horseplay handling

- Wiring faults with failure of safe electrical energy conditions

These can lead to damage to the working personnel, severe injuries due to existing electrical energy available in the equipment or even fatality.

Regulations guide for electrical switchgear risk assessment:

Electrical hazards inherently associated with electrical equipment and systems. but how to know what they are?

- Act of OSHA 1970 necessitates the employer to assess the workplace safety to determine if any hazards are present, or likely to be present, which requires the use of PPE.

- OSHA 1910-I specifying the hazard assessment and equipment selection requirements.

- NFPA 70E requires an electrical hazard risk assessment in the workplace and the use of the appropriate PPE and to ensure a safe workplace to perform any electrical analysis and to protect employees.

- IEEE-3007 section recommended practice for maintenance, management, and safety of industrial and commercial electric systems.

Figure.1: Electrical equipment incidents summary in a chemical industry

Safety programs aim to provide safe work instructions for a facility, avoiding risks.

When performing electrical switchgear risk assessment, it is very important to involve facilities employees. Employees are the one who work with electrical equipment directly, can help find and develop the best safety practice.

Electrical equipment risk assessments are particularly performed for ensuring equipment safety. Risk assessment involves identifying the undesired events, the causes, and the effects of these events.

A switchgear risk assessment performed in a top-down approach, to mitigate the risks systematic approach has been used.

A hostile operating environment means electrical equipment used in an operating environment like exposure to moisture, heat, vibration, corrosion. These conditions could result in damage to electrical switchgear.

Electrical switchgear that operates in a hostile environment must be inspected and assessed regularly.

A non-hostile operating environment means electrical switchgear used in an operating environment like dry, clean, free from damage to the equipment.

Electrical Switchgear Risk Assessment Steps

- Identifying the electric hazards associated with the respective work and the electrical system.

- Highlighting the possible failures that lead to electrical hazards and the potential harmful damage.

- Assessing the severity of the potential injury due to the electrical hazards.

- Determining the possibility of the occurrence for each hazard.

- Defining the level of risk for the associated hazard.

- Identifying the existing control methods

- If the level of risk is not acceptable, Identifying the additional control measures needs to be done within the electrical system.

These assessment processes carried out simply as follows:

Compromising the assessment process will decrease the likelihood of problems in the future

Identifying the hazards:

Preparing a diverse team of technicians as well as employees. Defining the scope of the assessment that is going to be performed.

Identifying hazards must take into consideration all the possible situations, events, tasks. The examination of hazards must consider the history of the minor and major failures of service experience on the switchgear also.

The age of electrical switchgear, operating environment of the equipment, and work practices and procedures are also must be taken into consideration.

Assess the risk:

To assess the electrical hazard risk, consider:

- The potential impact of the hazard

- Severity of the electrical hazard

- People are exposed to the hazard

- Possible hazard to cause harm

- Happen at any time or being a rare event

Table.1: Risk assessment – severity probability

Table.1: Risk assessment – severity probability

Control the risks:

After the identification of hazards and risk assessment of electrical switchgear and electrical switchgear, corrective control measures must be taken.

The hierarchy of risk control is performed from the highest priority level of protection and reliability to the lowest. Risk control could be elimination, substitution, or isolation method.

Review the control measures:

The control action taken to protect the health and safety must be reviewed to ensure the effectiveness it. When the control measure wasn’t effective, it is not reasonably practicable.

To enquire more about electrical equipment risk assessment and/or avail of our services, contact us.