The failure of any electrical system can have serious consequences, ranging from service interruption to the effective paralysis of an entire country.

Switchgear assembly forms the backbone of the electrical distribution network. Switchgear comprises the metal enclosure, the circuit breakers, protection relays, and the associated protection and control devices.

Switchgear assembly is used not only for protection, switching, and de-energize distribution system circuits, but also to include all the regulating, controlling, metering, and isolating devices.

A reliable and efficient switchgear set translates to a high-quality distribution network. The reliability and efficiency of the switchgear can be addressed in the design stage first and then during the operation and maintenance stage.

So, for safe work practice, workplaces will need to carry out a risk assessment on electrical switchgear assembly.

Care Labs provides electrical installation study, testing, inspection, and certification services for electrical projects. We have been offering risk assessment services for electrical switchgear.

Generally, switchgear assembly is reliable and stable. But the failure of electrical switchgear can cause severe injuries, major damage, and even death.

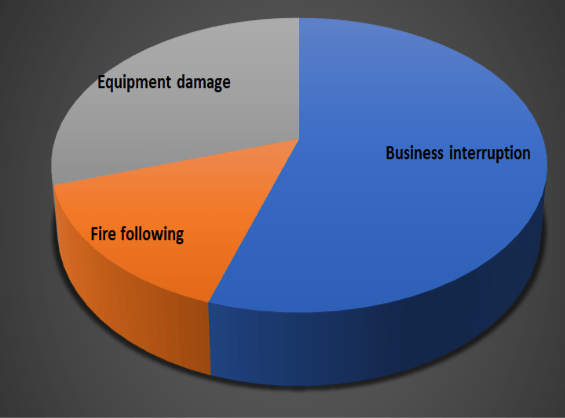

Beyond the loss of the switchgear set, it will result in catastrophic failure of controlled equipment, and business interruption.

As part of their efforts to ensure workplace safety, employers are required by the CSA Z462 Standard, and Occupational Health and Safety (OH&S) legislation to make suitable and sufficient assessments of the health and safety risks arising from their workplace operations.

The electrical switchgear risk assessment should include aspects such as the work organizing way, safety of the facility, effects on the local community, and ecology. The objective of a risk assessment is to identify all-hazard risks or potential risks arising from the work.

So that precaution can be taken to prevent damage to safe & health of workers and facility.

Figure.1: Effects of switchgear failure

The words ‘hazard’ and ‘risk’ are often used and are misunderstood.

Hazard – is the inherent property that could cause harm. Risk – is a combination of the probability of the hazard causing harm and the likelihood of occurrence of injury or damage to health, and the potential hazards.

In CSA Z462, Risk assessment is defined as is a comprehensive quantitative or qualitative evaluation of the probability that identifies hazards and estimates the potential severity of injury or threat to health that results from a hazard.

A risk assessment takes account of all the significant factors that can affect the chance of harm, examines the hazards, risks, and control measures relating to fire and rescue personnel, public when dealing with incidents involving electricity.

It should conclude on corrective measures needed to manage the risk for the benefit of workers and the organization.

Residual risk level | Not likely to occur | Could happen | Very likely to happen, frequently |

High- Risk level is unacceptable, severe consequences | High | High | High |

Medium-Risk level is acceptable, repairable damages | Low | Medium | Medium |

Low- Risk level is acceptable, | Low | Low | Medium

|

Table.1: Risk assessment matrix

Our distinct processes carried out to undertake risk assessment are:

If you own or operate this type of equipment in industrial or commercial organizations, periodic risk assessment on your facility electrical switchgear helps you to select, use and maintain switchgear safely and reduce the risk of accidents.

To know more about electrical equipment risk assessment and/or avail of our services contact us today!