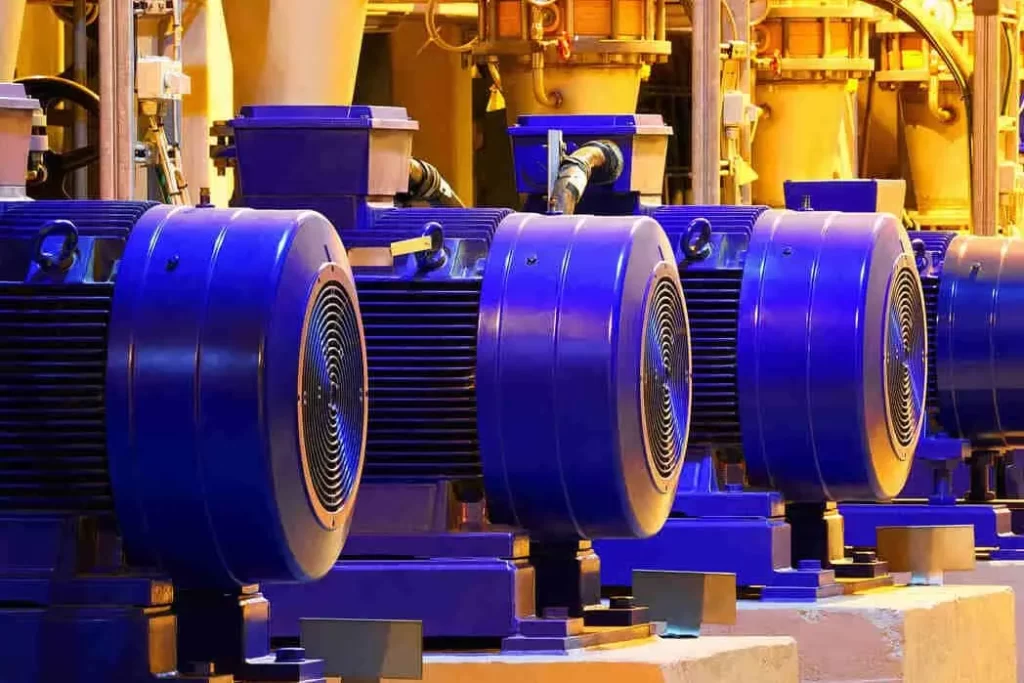

The electrical motor is the main component for many industrial applications that can account for up to 70% of the energy consumed, while up to 46% consumption for worldwide generated electricity.

Most likely, a big part of your monthly electricity bill goes for motor operation accounts. Far too often, electric motors are oversized and mismatched for the load which they intended to assist, or have been rewound several times.

To save your further expenses, you need to test Electrical Motors Efficiency of your electric motors.

What Does Care Labs Do?

Care Labs motor starting analysis service helps you to determine the efficiency of your electric motors, following national and international standards. We ensure that your efficiency of electrical motor complying with the Canadian Electrical Code (CEC).

Care Labs not only help in cut expenses by performing motor efficiency testing but also, improves productivity and reduces carbon emissions.

All electric motors are subject to Canada’s energy efficiency regulations, which set energy consumption performance standards.

The Efficiency of Electric Motors:

Efficient electricity use is not just good to have. In many circumstances, it is the mean difference between profitability and financial losses. The efficiency of your electrical motor makes the output of your electric motor more productive.

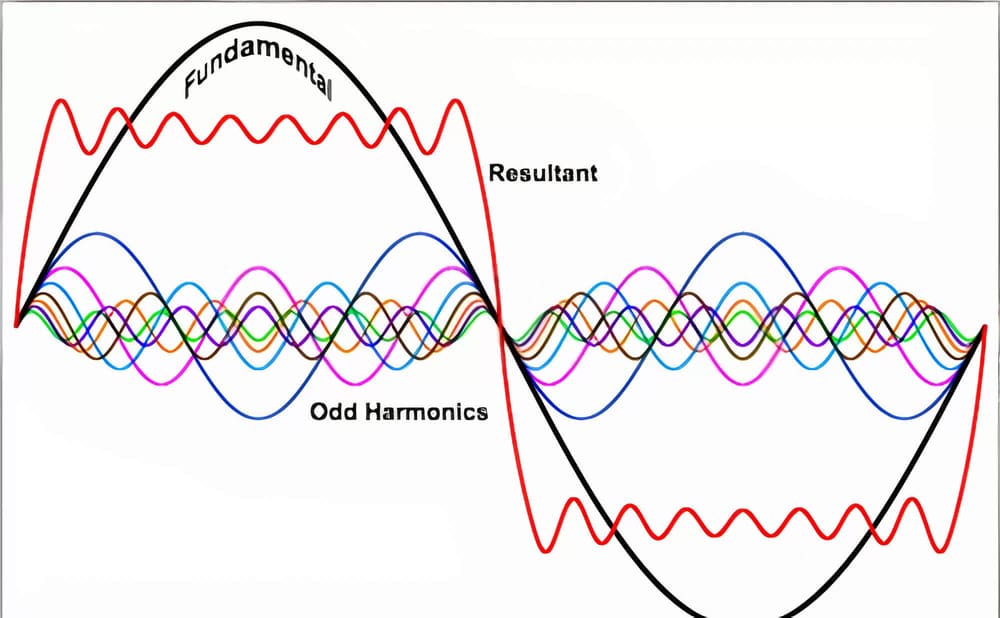

Efficiency can be calculated by:

Efficiency = Mechanical power/Electrical power

Nowadays, most electric motors are manufactured to run at a load of 50% to 100%, and the maximum efficiency usually are of the rated load is 75%. As an example: If we take a 10hp motor, then its load capacity is 5hp to 10hp and the peak efficiency is at approx. 7.5k.

A motor’s efficiency tends to decrease dramatically after getting 50% load.

The ISO 50001 standards provide a framework for establishing and implementing an energy management system for delivering sustainable savings.

How Much You Can Save?

In a word’s, lots. You know, the cost of the motor purchasing for about three percent of the unit’s total lifecycles cost. The remainder of the amount mostly you spend goes for the electricity bill. So, even a small improvement in the energy efficiency of one or two percent can make a big difference in the operating cost of motors.

How Do Care Labs Diagnose the Issues?

Nowadays for measuring motor performance and efficiency is well defined but hiring a Care Labs technician helps you to solve all motor efficiency problems.

The best way of covering issues related to motor efficiency is efficiency mapping and dynamo testing or dynamometer testing.

The organization that has implemented ISO 50001 has reduced energy costs and increase competitiveness while minimizing Green House Gases (GHG) and other environmental impacts.

Parameters of Electric Motors:

Each electric motor is designed for specific kinds of applications or devices depending on the load, and as such, each motor has different characteristics. These characteristics are classified according to International Electrotechnical Commission (IEC) standards and have a direct effect on the efficiency and operation of the motor.

In some cases, you see the motor is exceeding its expected running speed, in which case the motor lifespan may be shortened or pre-mature failure or damage may occur.

Benefits of Motors Start Analysis:

- Allowing you to improve your safety

- Enhance in energy efficiency

- Save your money from costly expenses and repairs.

- It helps to improve your electric motor reliability.

- Improve productivity by mitigating efficiency issues.

- Mitigate the losses can be devastating, sometimes maybe the reason for malfunction or downtime.

Care Labs uses the latest software to calculate slip, speed, electrical torque output, load current, and terminal voltage data at discrete time intervals. The study of electrical motor efficiency helps to verify that the efficiency of the electric motor is up to date with IEC standards.

A routine program of minor inspection, repairs, verification, and testing can improve motor efficiency. It can also assist in prevent or delay failure and reduce downtime.

Care Labs provide services for motor start analysis in Canada, UAE, and many more countries. We deliver quality work to work on, services provided by Care Labs give your business wings to fly.

Contact us today to know more about motor start analysis services offered by Care Labs and get a quote.