A Comprehensive

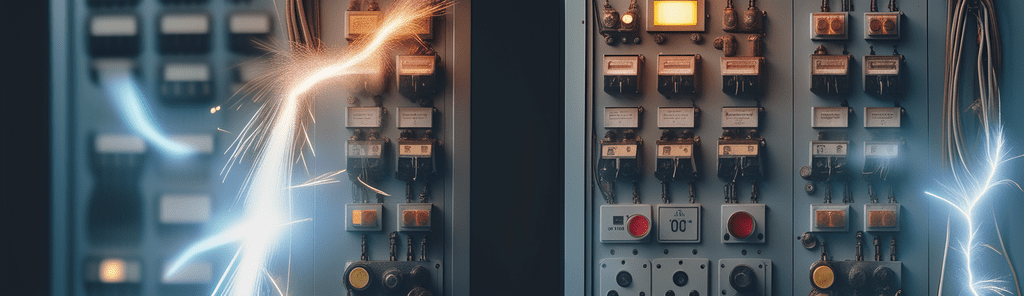

Introduction to Arc Flash Analysis

in South Africa:

Electrical discharges happen when a gas is subjected to a voltage that is higher than its insulating capacity. This causes the gas to release electrons into the surrounding space. The arc will start to develop as soon as the voltage is high enough to ionize the air in the gap between the conductors. When a gas undergoes the process of ionization, it is converted into an excellent conductor. This enables the flow of current and results in the production of an arc-shaped current that is known as an arc flash. An unintended electrical discharge that results in a fire is referred to as an arc fault.

- The elevated temperatures of an arc discharge result in overwhelming luminosity and deafening noise.

- An arc detonation is a high-pressure wave with the potential to discharge fragments and liquid metal.

- Vaporous toxins

Concerns about arc discharge have the potential to adversely hurt both business operations and electrical infrastructure. As a result of arc discharge dangers, businesses suffer the following losses:

- Additional costs for medical care, rehabilitation, workers’ compensation, and costs associated with the accident investigation and delay in production.

- Legal fees and judgments related to a dispute, as well as fines, insurance premiums, and costs associated with the replacement and rehabilitation of individuals.

- Effects detrimental to the company’s reputation and brand.

- A loss of business opportunities brought on by a history of incidents that could lead to the revocation of an electrical license.

Reasons for Electrical Arc Flash:

- Destruction of a conductor’s insulation

- Responsibility of humans

- Incorrect switch and circuit breaker maintenance

- When water is near the apparatus, there is cause for concern.

- Unplug any panels that have been blocked.

- Arrangement of wiring for high voltage

- Discharge by ionization

- Equipment and apparatus with defects

Arc Flash Analysis Methodologies:

Whenever high-voltage or low-voltage, high-current toggling occurs, the possibility of an arc discharge exists.

Evaluate the Risk of Arc Flash:

- Conduct an arc flash/fault analysis or study, which includes data collection, software-based power system modeling, short circuit analysis, overcurrent protective device coordination study, arc flash analysis, and arc flash evaluation.

- Assessment of a worker’s potential arc discharge exposure

Risk Management:

- To reduce worker exposure to arc discharge hazards, only interact with equipment that is deactivated.

- It is necessary to replace manual systems with automated ones.

- To safeguard workers from potential hazards, erect physical barriers between them and move machinery.

Engineering Management:

- Reduce the short circuit current to lessen the incident energy.

- Detection and suppression of arc discharge equipment

- containing and remote controls

- Modifications or upgrades to the switchboard

- Installing irreversible circuit breakers

- Material for insulation of transit rail

- Replacement of blown circuits

Procedures Administrative:

- Developing energy measurement indicators for manufacturing facilities, switch rooms, and other locations.

- Identifying the perimeter of an arc

- Data collection and documentation for Arc flash.

- Providing methods and procedures to reduce exposure through prevention.

- Personal protective equipment (PPE) levels and incident energy management implementation

Equipment Protective to the Individual (PPE):

- Personal protective equipment can mitigate the severity of an injury but cannot prevent it. It may reduce the severity of an injury despite being the least effective treatment. Personal protective equipment (PPE) is utilized according to the severity of the incident.

CareLabs has a remedy for every hazard associated with arc flashes. Assessing the risks posed by arc flash hazards and implementing effective mitigation and control measures to protect your property and personnel are tasks that are best delegated to professionals with the necessary training and experience.

CareLabs Service Advantages:

- Safer electrical systems that adhere to regulatory standards.

- Fully integrated power systems are labor and cost efficient.

- Create a workplace that is secure.

- When a circumstance calls for simple solutions, provide them.

- Boost the margins of safety.

- You can save time by automatically generating arc flash labels and work permits.

- Avoid penalties and legal expenses.

To ensure that workers are easily reachable in the event of a routine or urgent emergency, CareLabs has staff members stationed in different places. CareLabs has acquired a customer with a superb reputation and quickly established itself as an ISO 9001:2008-accredited company. Arc flash investigation and analysis services are available from CareLabs in all of South Africa’s major cities, including Johannesburg, Cape Town, Durban, and Pretoria.

Related News

Significant Is Harmonic Analysis in South African

Firm?

South African Electrical Motor Performance Regulations Compliance:

How Significant Is Harmonic Analysis in South African Firm?

Why Does South African Business Need Short Circuit and Load Flow Analysis?