Portuguese Arc Flash Analysis: A Comprehensive Guide

Electrical arcs form when a gas is exposed to a voltage greater than the voltage it can block. The arc occurs when the voltage is high enough to ionize the air between the conductors. When a gas is ionized, it turns into an excellent conductor, enabling current to flow and producing an “arc flash” of arched-shaped lightning. An arc fault is an electrical discharge that was not planned.

- Arc flashes create dazzling brilliance and deafening loudness due to their hot temperatures.

- An arc blast is a high-pressure wave that may propel molten metals and metal particles into the atmosphere.

- Toxic vapors

Arc flash hazards are potentially devastating for enterprises and electrical infrastructure. The following are examples of company losses caused by arc flash dangers:

- Medical treatment, rehabilitation, worker’s compensation, accident investigation, and production downtime incur additional expenses.

- Legal fees, penalties, insurance premiums, repair expenditures, and the cost of finding a substitute worker associated to litigation.

- An unfavorable impact on the organization’s brand and reputation.

- Loss of business possibilities due to a history of accidents, which might result in the termination of an electrical license.

The Subsequent Causes an Arc Flash:

- Insulation on a deteriorating conductor

- The bodily parts that are on display

- Individual irresponsibility

- Insufficient upkeep of switches and circuit breakers

- The water is near the gadget.

- Remove all obstacles from the route.

- Elevated voltage wiring

- Destruction of electrostatic charge

- Ruined devices and apparatus

Methodology for Arc Flash Evaluation:

Whenever high-voltage or low-voltage, high-current switching occurs, arc flash hazards may exist.

Step 1: Estimate the likelihood of an arc flash:

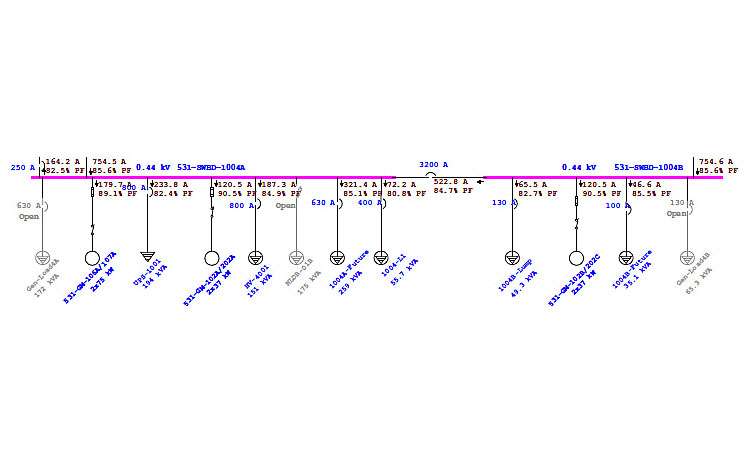

- As part of an arc flash/fault study or analysis, collect data, model the power system using software, analyze short circuits, investigate how overcurrent protection devices interact, analyze arc flashes, and evaluate arc flashes.

- Assessing the likelihood of an employee being hurt by an arc flash

Step 2: React to the danger:

- If workers only handle equipment that has been switched off, they are less likely to be injured by arc flashes.

- Utilizing automated methods would be preferable than manual ones.

- Install physical barriers between employees and all active equipment for their protection.

Step 3: Engineer control:

- Reduce the fault current to reduce incident energy.

- Systems for the detection and suppression of arc flash

- Control devices and remote controls

- Changes or improvements to the switchboard

- Circuit breakers that do not trip

- Insulation of bus bars is important.

- Replace blown out fuses.

Step 4: Administrative controls:

- Labeling switch rooms, plants, and other vital areas to determine where energy levels are occurring.

- Noting the perimeters of the arc

- Developing arc flash diagrams and making notations

- Implementing safe practices and standards to reduce exposure

- Utilizing incident energy and levels of personal protective protection (PPE)

Step 5: Personal protective equipment (PPE):

- Even though it is the least effective PPE, it may mitigate an accident’s severity, but it cannot prevent it. The choice of personal protection equipment (PPE) depends on the severity of the scenario.

CareLabs can assist you with any issues linked to arc flash. To guarantee the safety of your workers and property, professionals with extensive training and understanding can identify arc flash dangers and recommend the most efficient techniques for minimizing and managing them.

The Advantages of CareLabs Service:

- More secure electrical systems that comply with regulatory criteria and rules

- Increasing productivity saves time and money.

- Enhance worker safety.

- Provide rapid options in the event of an emergency.

- Increase the margins of safety.

- Create work permits and arc flash labels automatically to save time.

- Protect yourself against penalties and legal costs.

CareLabs employs personnel in many locations to ensure that our professionals are nearby in the event of an emergency or for normal tasks. CareLabs immediately attained ISO 9001:2008 certification and built a clientele with a solid reputation and positive comments. CareLabs offers arc flash testing and analysis in all of Portuguese‘s main cities, including Lisbon, Porto, Vila Nova de Gaia, and Braga.

Share Post

Related Posts

-

How to Conduct a Power Quality Analysis in Portugal?

-

Power Quality Working Principles in Portugal

-

The Importance of Load Flow and Short Circuit Analysis for a Portuguese Business

-

Test and Verify Electrical Motor Efficiency in accordance with Portuguese Guidelines

-

How to evaluate efficiency and dependability of commercial motors?

-

Arc Flash Analysis in Portugal: A Step-by-Step Guide

-

Load Flow, Short Circuit, and Relay Coordination in Power System Analysis

-

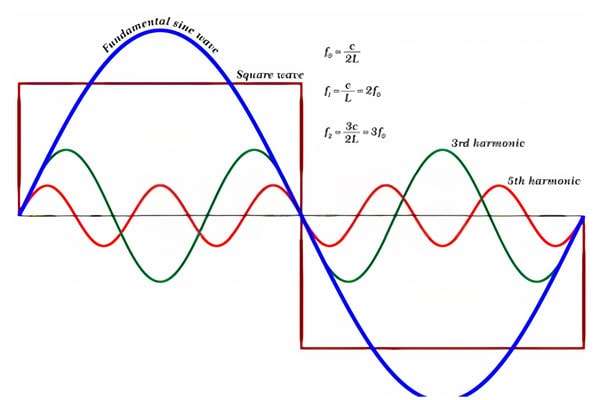

Why is Harmonic Analysis and Study Important for Portuguese Businesses?

-

Importance of Arc Flash Hazard Analysis and Mitigation Methods

-

Harmonic Analysis in Power System in Portugal