How Can the Performance and Dependability of Commercial Motors Be Measured?

Improving energy efficiency is the cleanest, least expensive, and quickest way to provide reliable electricity. Approximately 46% of all power utilized and 69% of all industrial energy is used by motors. The usage of energy is one of the most important challenges that many businesses must face. The first issue that must be addressed is the inadequate architecture and power usage. Bad design and incorrect use are the key reasons for high-power prices and difficulties in meeting the growing energy demand. Most motors run between 50% and 100% of their rated load, although their greatest efficiency is achieved at 75% of their rated load and begins to drop as the motor ages. After 50% load, an electric motor’s efficiency begins to drop on its own.

Four Elements Influence the Performance of a Motor:

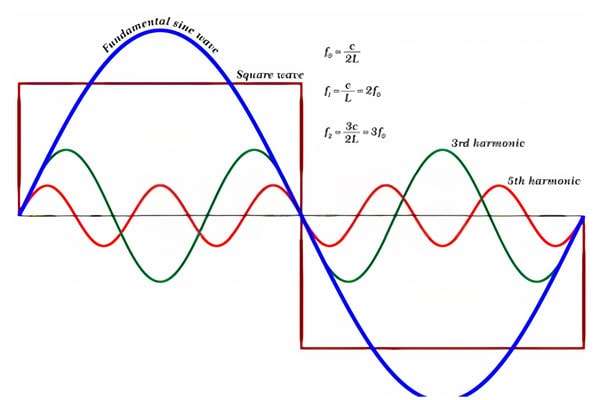

- Transients, imbalances, sags, swells, and harmonics can cause severe damage and, in extreme situations, render the motor inoperable.

- When a motor generates rotational force to drive a mechanical load at the rated speed of the spinning shaft, efficiency and overall performance are compromised. The dependability of the electric motor is ensured by its operation at the set frequency and torque speed. It is possible to determine the efficiency of an electric motor by measuring torque.

- The specifics of the electric motor’s operation and what to expect from it: When a motor is mechanically overworked, it places stress on its connections, bearings, and insulation. This decreases the motor’s efficiency and may lead to its failure or untimely demise.

- In conclusion, the efficiency of a motor has a direct effect on the bottom line. Predictive and preventive maintenance begins with the collection of baseline data.

75% of industrial motor failures result in yearly plant shutdowns of one to six days. 90% of motor failures following a warning happened within a month, whereas 36% occurred within a day. To avoid motor failure and operating issues Evaluating, analysing, inspecting, and auditing your electric motors on a regular basis will help you avoid problems and improve their performance and dependability.

Statistics Regarding the Enhancement of Motor Performance:

Boost the efficiency of an induction motor by 68% over a 53-year period. (1960 to 2013). Reducing losses in electric induction motors will boost their efficiency over the course of a year. The use of energy by an induction motor has decreased with time (data of 45 kW, 4p design motor). CareLabs investigates the performance and dependability of electric motors in a range of commercial buildings and enterprises. We examine and diagnose the issue, allowing you to decrease losses and improve motor efficiency. As skilled and experienced professionals, we endeavor to give our clients superior service.

CareLabs' Services Give Various Advantages:

- Always bears responsibility for our acts.

- Provide outstanding service to your customers.

- Responds quickly to your talks.

- Our team is strengthened by the presence of a skilled and reliable electrician.

- Understanding of Portuguese standards.

- Plan a time that is convenient for you.

- Provide a comprehensive report in digital format to assure your satisfaction.

Methods for Evaluating Electric Motor Performance:

- Before conducting the audit, we gather all documents pertaining to the site for inspection.

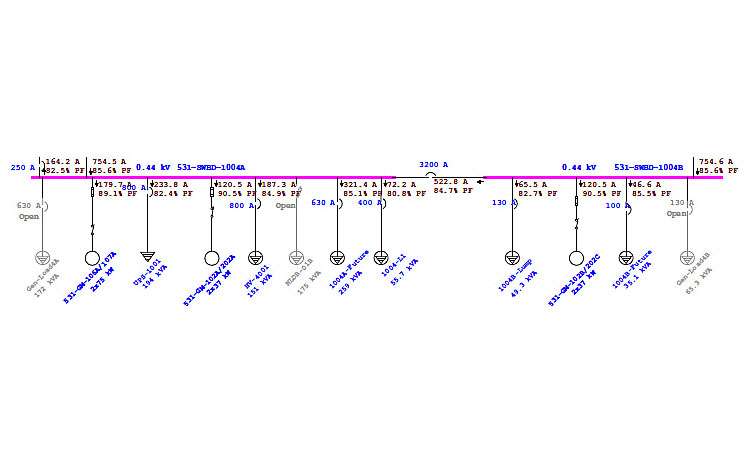

- To improve your standing, develop a one-line diagram and a check list.

- Use the electrical motor inspection checklist to continue the audit.

- Specialists evaluate and inspect the electric motor after finishing the check list.

- Obtain the examination results for the electric motor.

- Ensure that the load flow and power quality are not compromised.

- Our professionals will guarantee that any concerns are rectified if they arise.

- Ensure that your motor’s performance meets national standards.

- Deliver an electronic report and safety suggestions.

CareLabs conducts motor acceleration research to guarantee that the motor works well under high-load conditions and enhances productivity (by mitigating the losses). Eliminating losses improves the reliability of motors. We provide motor start analysis services in all major cities, including Lisbon, Porto, Vila Nova de Gaia, and Braga. Contact CareLabs for auditing the efficiency of commercial electric motors and for a quote.

Share Post

Related Posts

-

How to Conduct a Power Quality Analysis in Portugal?

-

Power Quality Working Principles in Portugal

-

The Importance of Load Flow and Short Circuit Analysis for a Portuguese Business

-

Test and Verify Electrical Motor Efficiency in accordance with Portuguese Guidelines

-

How to evaluate efficiency and dependability of commercial motors?

-

Arc Flash Analysis in Portugal: A Step-by-Step Guide

-

Load Flow, Short Circuit, and Relay Coordination in Power System Analysis

-

Why is Harmonic Analysis and Study Important for Portuguese Businesses?

-

Importance of Arc Flash Hazard Analysis and Mitigation Methods

-

Harmonic Analysis in Power System in Portugal